Calcining device capable of separating powder from crushed stone after crushing of limestone

A calcination device and limestone technology, which is applied in the field of lime, can solve the problems of incomplete heating of limestone, affecting product quality, and difficulty in reaching the required temperature in the calcination furnace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

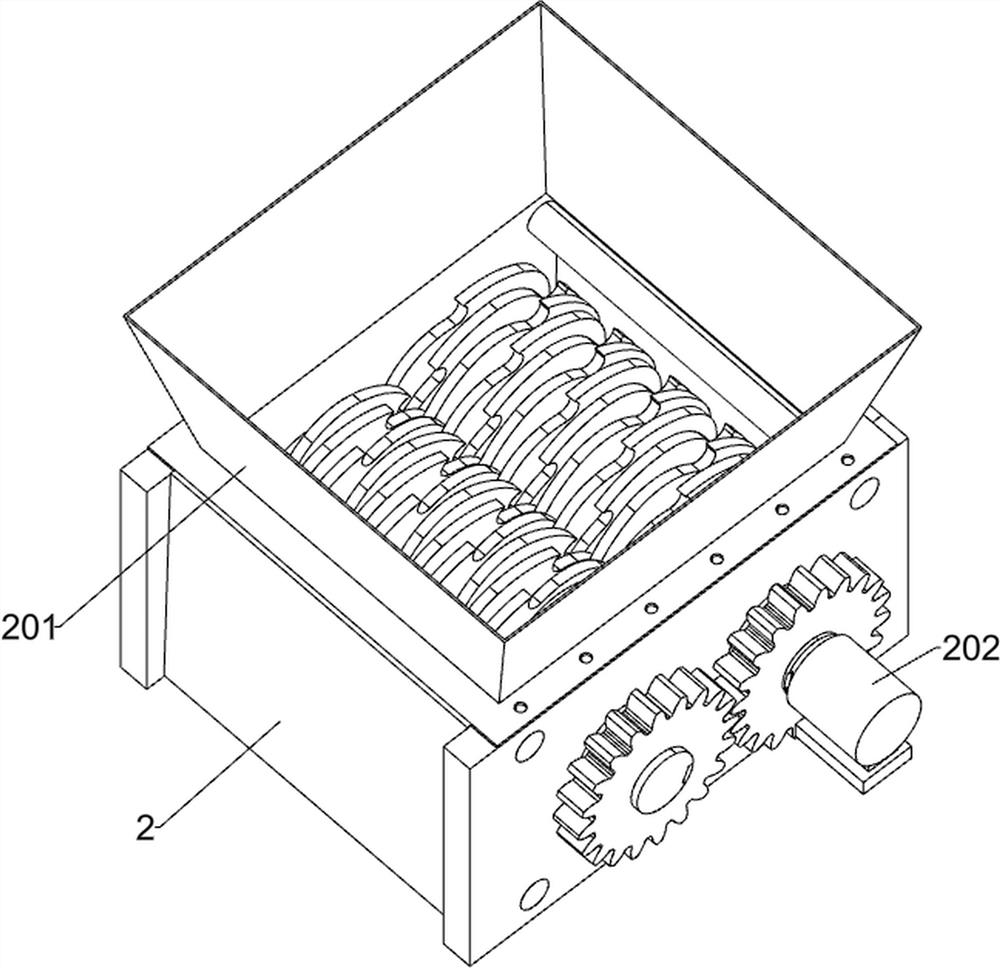

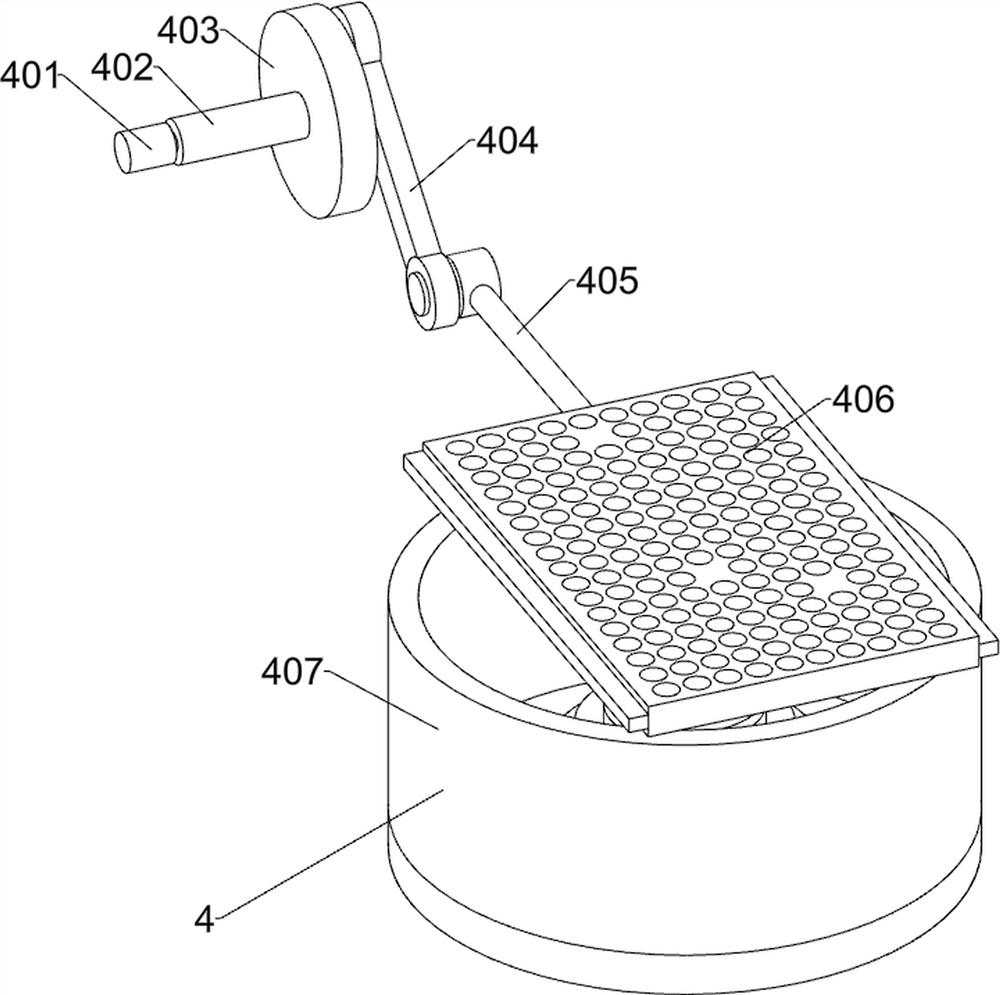

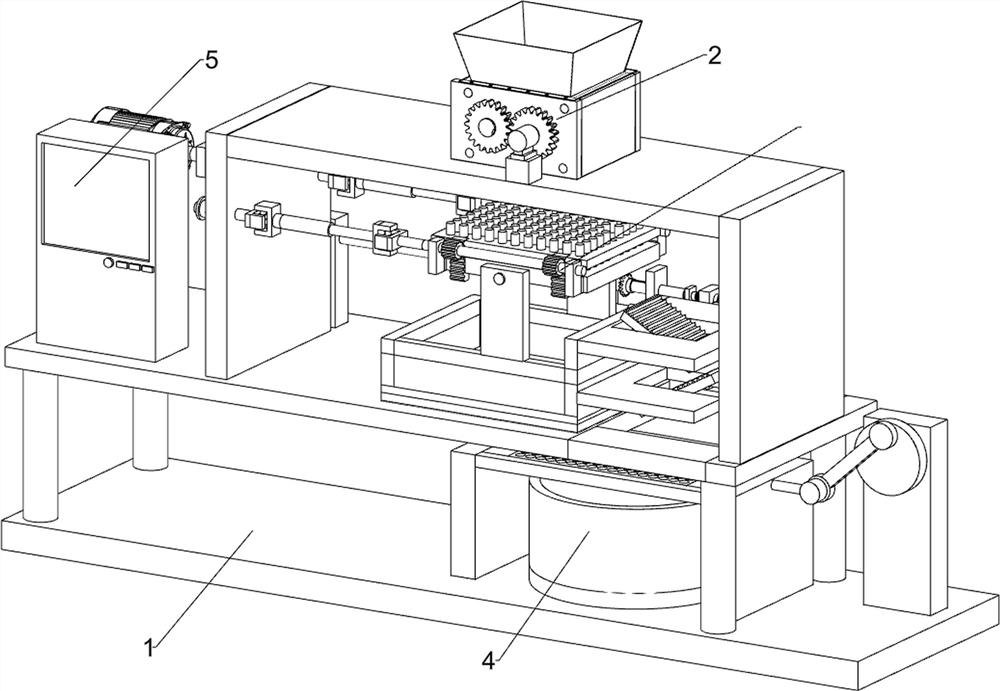

[0031] A device for separating powder and crushed stone after crushing limestone, such as Figure 1-10 As shown, it includes a bottom plate assembly 1, a crushing unit 2, a powder separation unit 3, a calcination unit 4 and a control panel 5; the bottom plate assembly 1 is connected with the crushing unit 2; the bottom plate assembly 1 is connected with the powder separation unit 3; the bottom plate assembly 1 It is connected with the calcining unit 4; the bottom plate assembly 1 is connected with the control panel 5.

[0032] Working principle: When in use, place a limestone crushed, separated powder and crushed stone calcination device at the position to be used, then connect the external power supply, and start it through the control panel 5; firstly, the staff will place the larger limestone in the The crushing unit 2 fixed on the bottom plate assembly 1, then, use the crushing unit 2 to crush the limestone, and then transfer the crushed limestone to the powder separation ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap