A method and device for friction-assisted riveting of ultra-thin plates

A plate and riveting technology, which is applied in the field of friction-assisted riveting of ultra-thin plates, can solve the problems of complex structure of the device, damage to the strength of the base material, and poor reliability, and achieve the effects of simple operation steps, improved efficiency, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

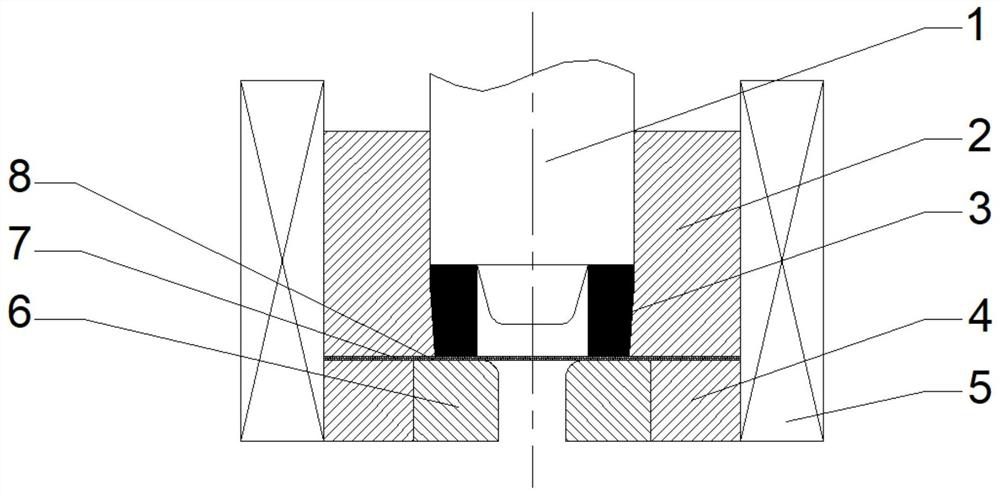

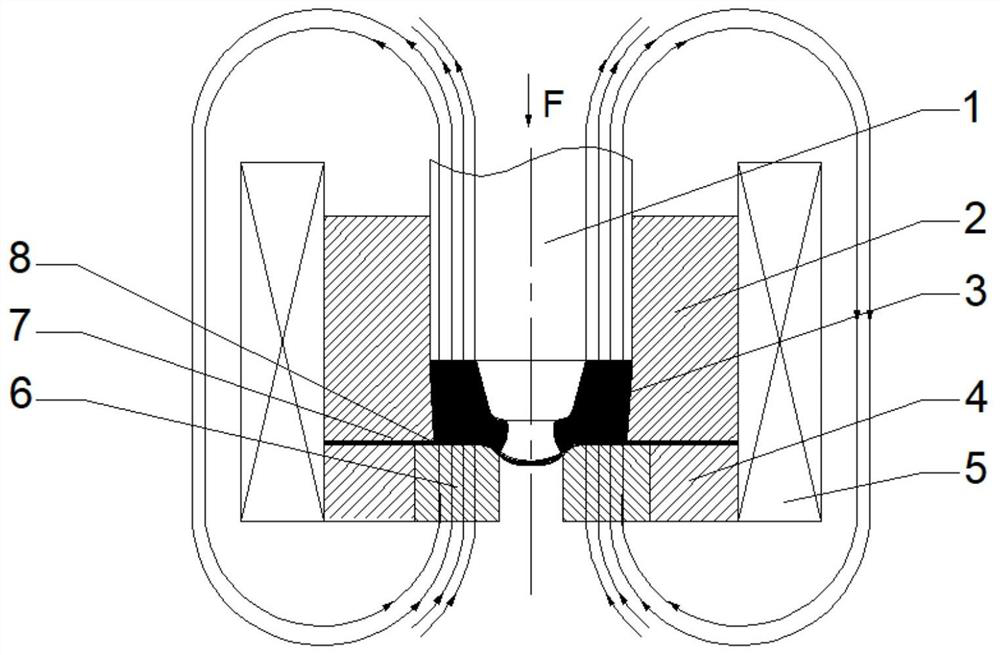

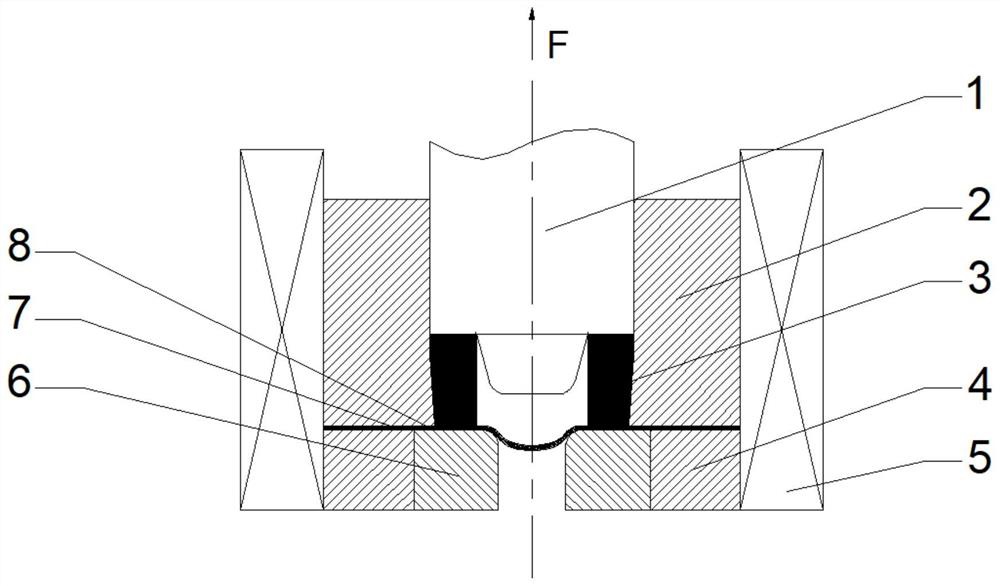

[0045] A method for friction-assisted riveting of ultra-thin plates of the present invention, the device used is such as figure 1 As shown, it includes an extrusion punch 1, a blank holder 2, a magnetorheological elastic ring 3, a lower die 4, a coil 5, a first die 6, a second die 9, a forming punch 10, and a flat bottom punch 11. ; The extrusion punch 1 is a cylinder with a boss at the working end, and the height of the boss is less than the height of the magneto-rheological elastic ring 3; the forming punch 10 is a cylinder with a protrusion in the middle of the working end; the flat-bottom punch 11 is a cylinder body; the edge of the cavity entrance of the first concave mold 6 is a transition fillet; the cavity diameter of the second concave mold 9 is larger than that of the first concave mold 6 .

[0046] The upper plate 7 and the lower plate 8 are generally copper foil or aluminum foil with a thickness of 30-70 μm.

[0047] In a preferred embodiment of the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com