Method of assembling a lower electrode mechanism for welding and lower electrode mechanism for welding

An assembly method and electrode mechanism technology, applied in welding equipment, electrode features, welding medium, etc., can solve the problems of reduced stroke detection accuracy, bad influence on welding quality, and inability to replace, and achieve easy connection, reliable connection, and durability. Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be described.

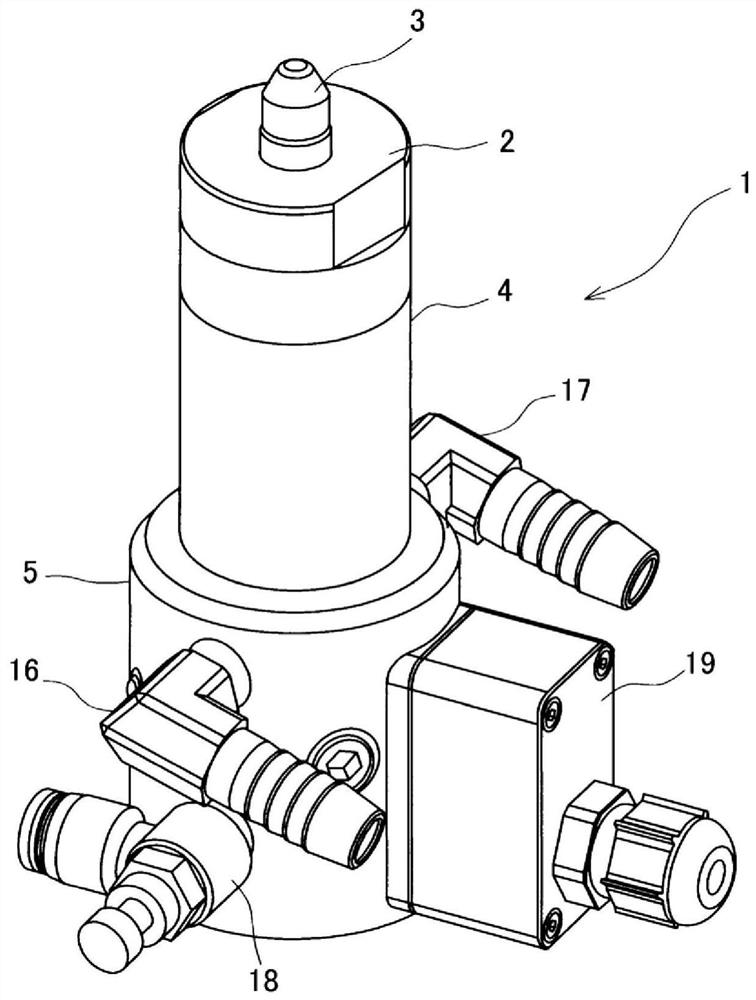

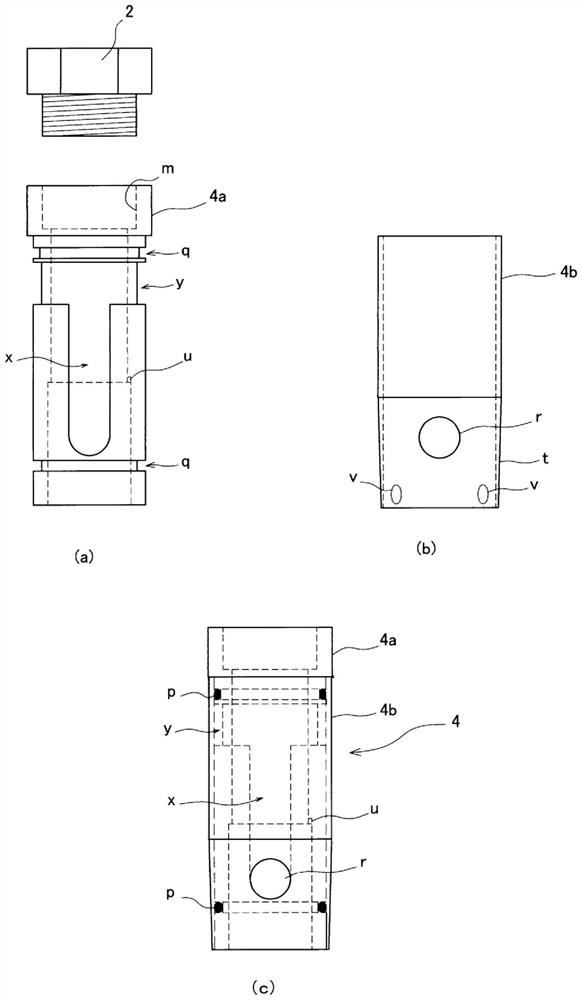

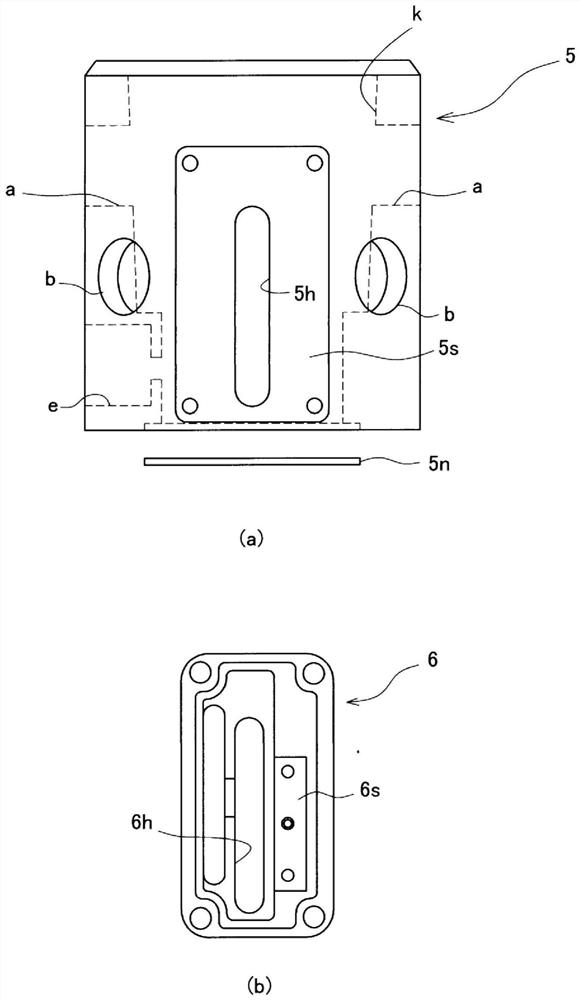

[0038] The lower electrode mechanism for welding according to the present invention relates to a lower electrode mechanism for downsizing and simplification in a resistance welding machine that conducts welding by applying pressure while clamping an object to be welded. At the same time, the technology to improve the welding quality, in which the lower electrode mechanism is used in combination with the upper electrode mechanism, and the technology of utility model registration No. Improvements such as dew condensation that tends to occur on the periphery or around the rod of the central axis will adversely affect the slide sensor, and ease of handling when replacing the slide sensor.

[0039] Hereinafter, it will be described based on the drawings, figure 1 It is an overall view of the lower electrode mechanism 1 for welding, which is arranged below the upper electrode mechanism not shown, and is welded between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com