Detection method of welding defect rate and bonding rate of target components

A welding defect and detection method technology, which is applied in the direction of analyzing solids by using sound waves/ultrasonic waves/infrasonic waves, can solve the problems of low detection accuracy of welding defect rate and bonding rate, and can not reflect the welding status of target components well, etc., to achieve The effect of saving raw materials, accurate detection accuracy, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

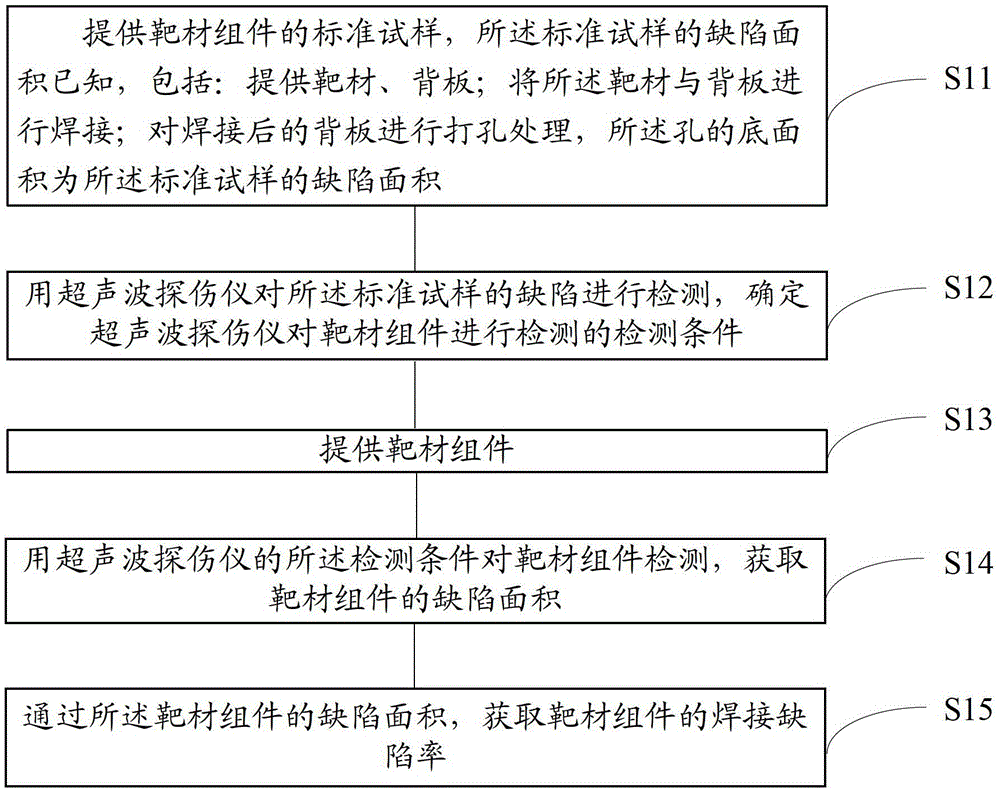

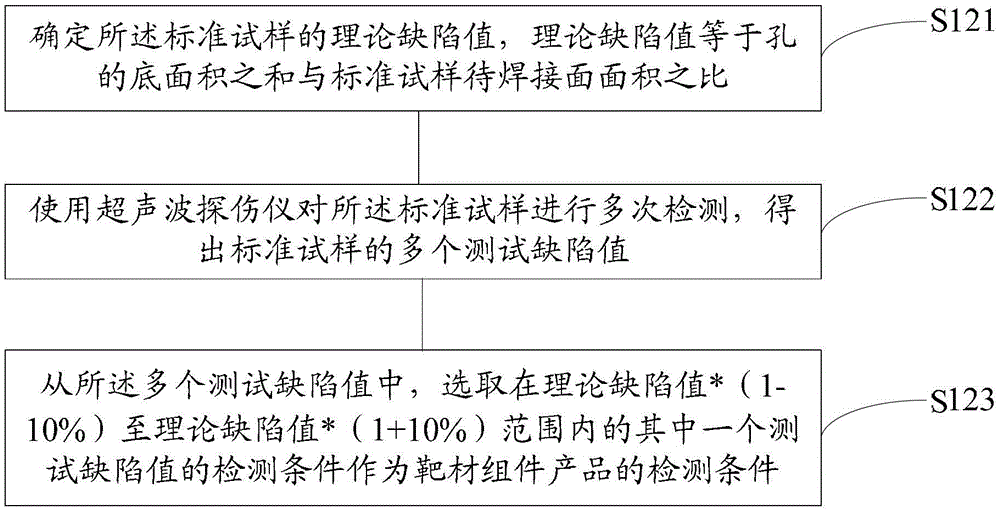

Method used

Image

Examples

Embodiment Construction

[0039] After careful research and analysis, the inventor found that the existing detection methods for the welding defect rate and bonding rate of target components have limitations, especially the detection accuracy of the welding defect rate and bonding rate is not high, and cannot reflect the entire target component well. The reasons for the welding condition of the material components are:

[0040] In the prior art, the detection of welding defect rate of target components generally adopts radiographic inspection method, which refers to the non-destructive testing method that uses x-rays or gamma rays to penetrate target components and uses film as the recording information. The specific principle is: when x-rays or γ-rays irradiate the film, the silver halide in the emulsion layer of the film can produce a latent image. Since substances with different densities have different absorption coefficients of rays, the energy of rays irradiated to various parts of the film will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com