Automatic assembly equipment for intelligent manufacturing of tire pressure sensor

A tire pressure sensor, intelligent manufacturing technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing, etc., can solve the problems of large labor force, single assembly line, affecting the assembly efficiency of tire pressure sensor, etc., to reduce labor force and improve transportation efficiency. , the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

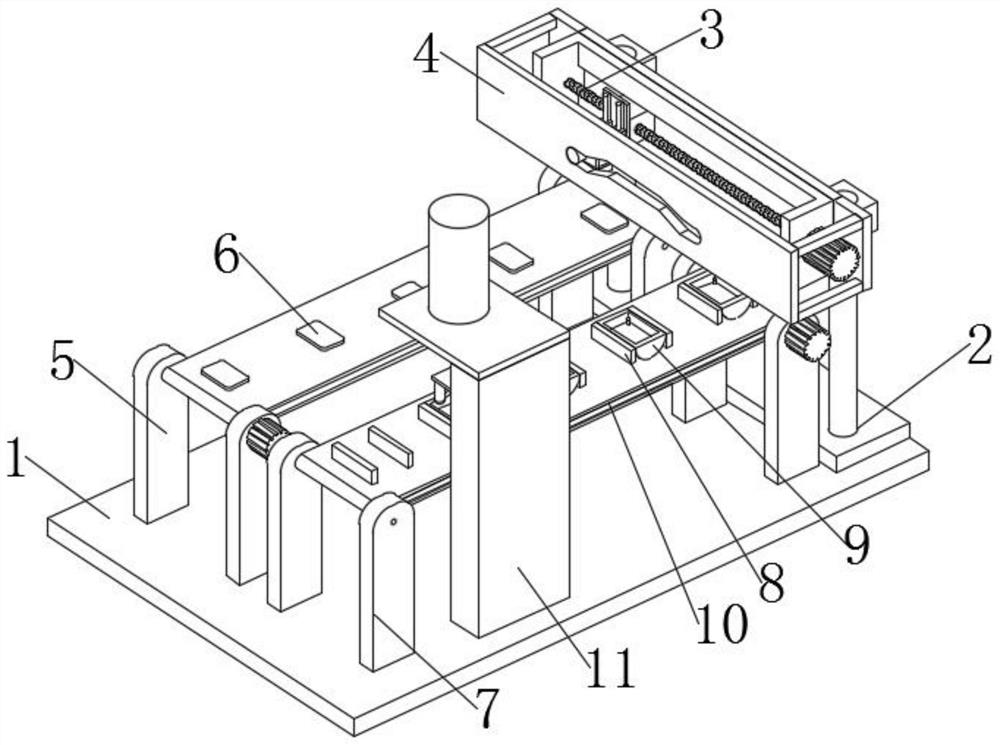

[0030] An automatic assembly equipment for intelligent manufacturing of tire pressure sensors, such as figure 1 As shown, it includes a base 1, a support device 2 is fixedly connected to the rear of the upper end of the base 1, a clamping device 3 is movably interspersed in the support device 2, the front end of the support device 2 is fixedly connected to the limit device 4, and the left part of the upper end of the base 1 is fixedly connected There is a first conveyor belt 5, the upper end of the first conveyor belt 5 is equidistantly provided with several circuit boards 6, the right part of the upper end of the base 1 is fixedly connected with a second conveyor belt 7, and the upper end of the second conveyor belt 7 is equidistantly provided with two for A group of several sets of limit strips 8, and several sets of limit strips 8 are interspersed with shells 9, the second conveyor belt 7 is fixedly interspersed with force plates 10, and the front part of the upper end of th...

Embodiment 2

[0033] On the basis of Example 1, as Figure 2-5As shown, an automatic assembly equipment for intelligent manufacturing of tire pressure sensors includes a base 1, a support device 2 is fixedly connected to the rear of the upper end of the base 1, a material clamping device 3 is movably interspersed in the support device 2, and the front end of the support device 2 is fixedly connected Limiting device 4, the upper left part of the base 1 is fixedly connected with the first conveyor belt 5, the upper end of the first conveyor belt 5 is equidistantly provided with several circuit boards 6, the upper right part of the base 1 is fixedly connected with the second conveyor belt 7, the second The upper ends of the two conveyor belts 7 are equidistantly provided with two groups of limiting strips 8, and the casings 9 are interspersed in the several groups of limiting strips 8, and the second conveyor belt 7 is fixedly interspersed and connected with force plates. 10. A pressing device...

Embodiment 3

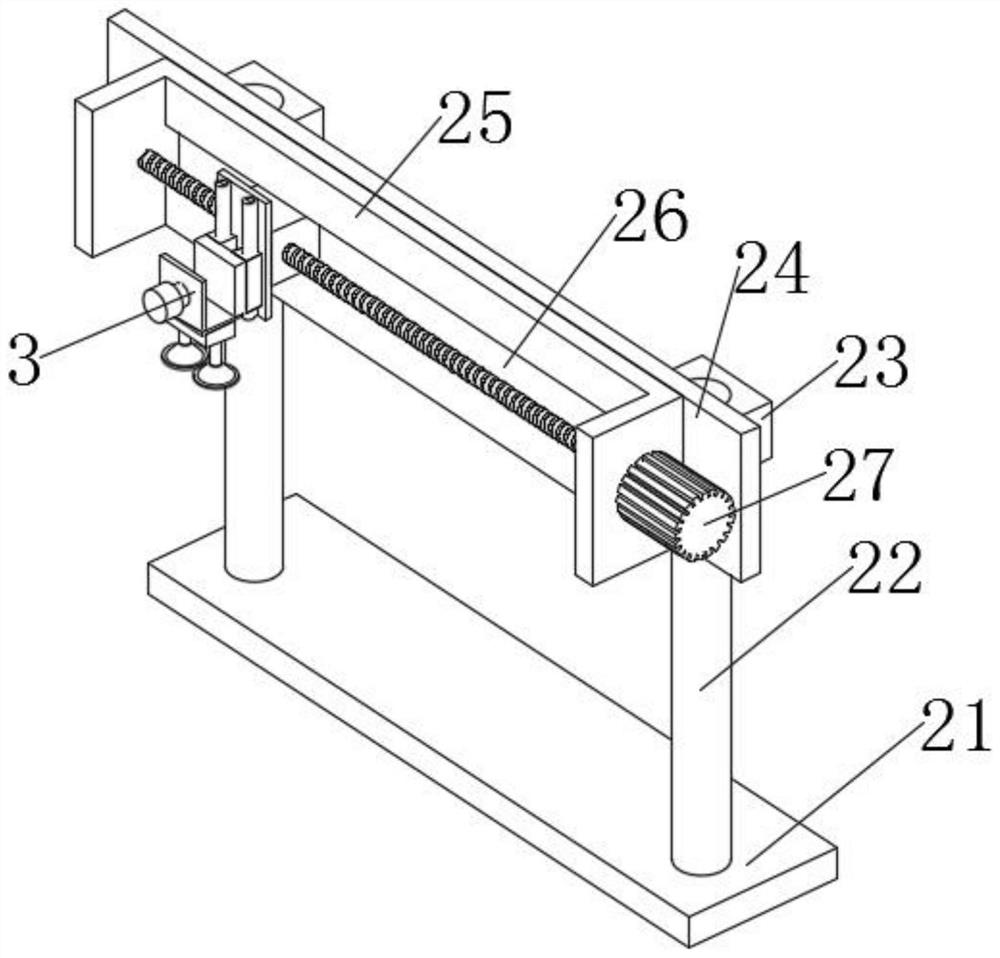

[0036] On the basis of Example 1, as Image 6 As shown, an automatic assembly equipment for intelligent manufacturing of tire pressure sensors includes a base 1, a support device 2 is fixedly connected to the rear of the upper end of the base 1, a material clamping device 3 is movably interspersed in the support device 2, and the front end of the support device 2 is fixedly connected Limiting device 4, the upper left part of the base 1 is fixedly connected with the first conveyor belt 5, the upper end of the first conveyor belt 5 is equidistantly provided with several circuit boards 6, the upper right part of the base 1 is fixedly connected with the second conveyor belt 7, the second The upper ends of the two conveyor belts 7 are equidistantly provided with two groups of limiting strips 8, and the casings 9 are interspersed in the several groups of limiting strips 8, and the second conveyor belt 7 is fixedly interspersed and connected with force plates. 10. A pressing device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com