Positioning jig for 5G communication module manufacturing and use method thereof

A communication module and positioning fixture technology, which is applied in the direction of manufacturing tools, conveyor objects, transportation and packaging, etc., can solve the problems of large contact wear of communication modules, affecting the processing process, and inconvenient blanking, so as to improve the processable area, Effect of reducing frictional damage and improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them. The electrical components involved in the embodiments (not specifically marked and illustrated) all adopt the prior art.

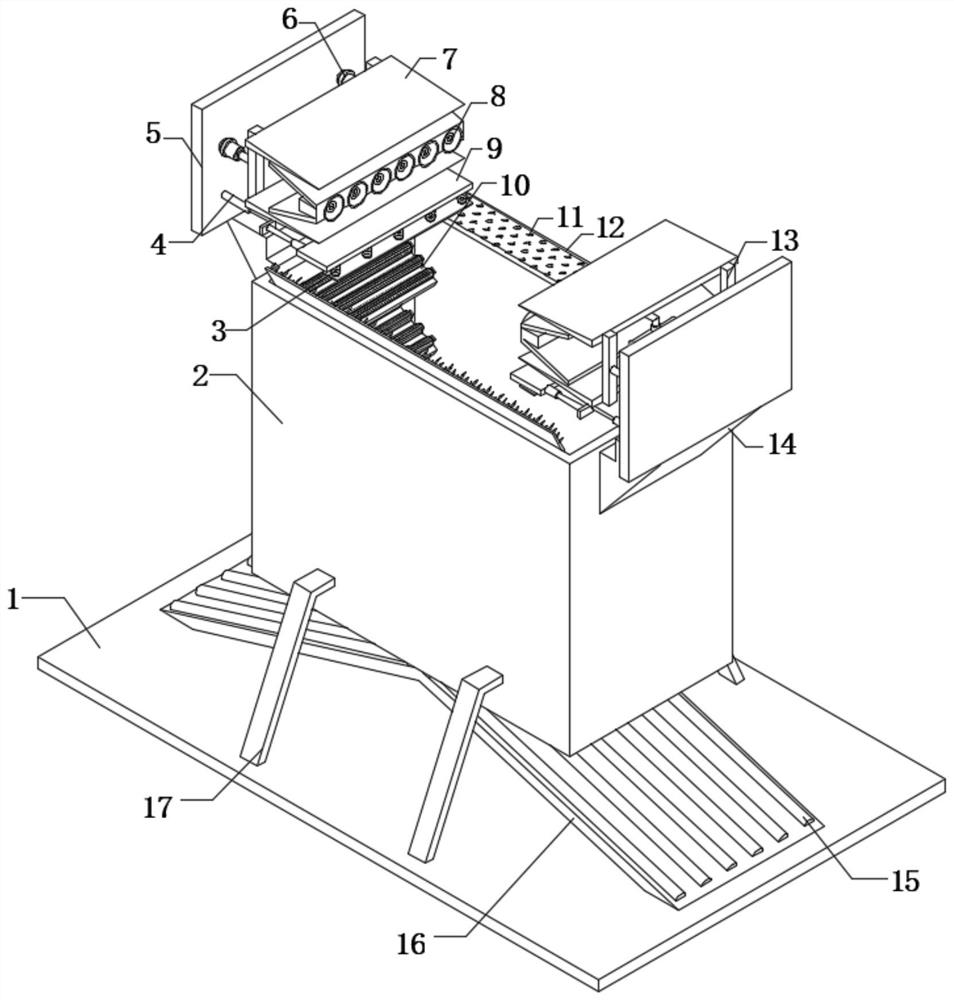

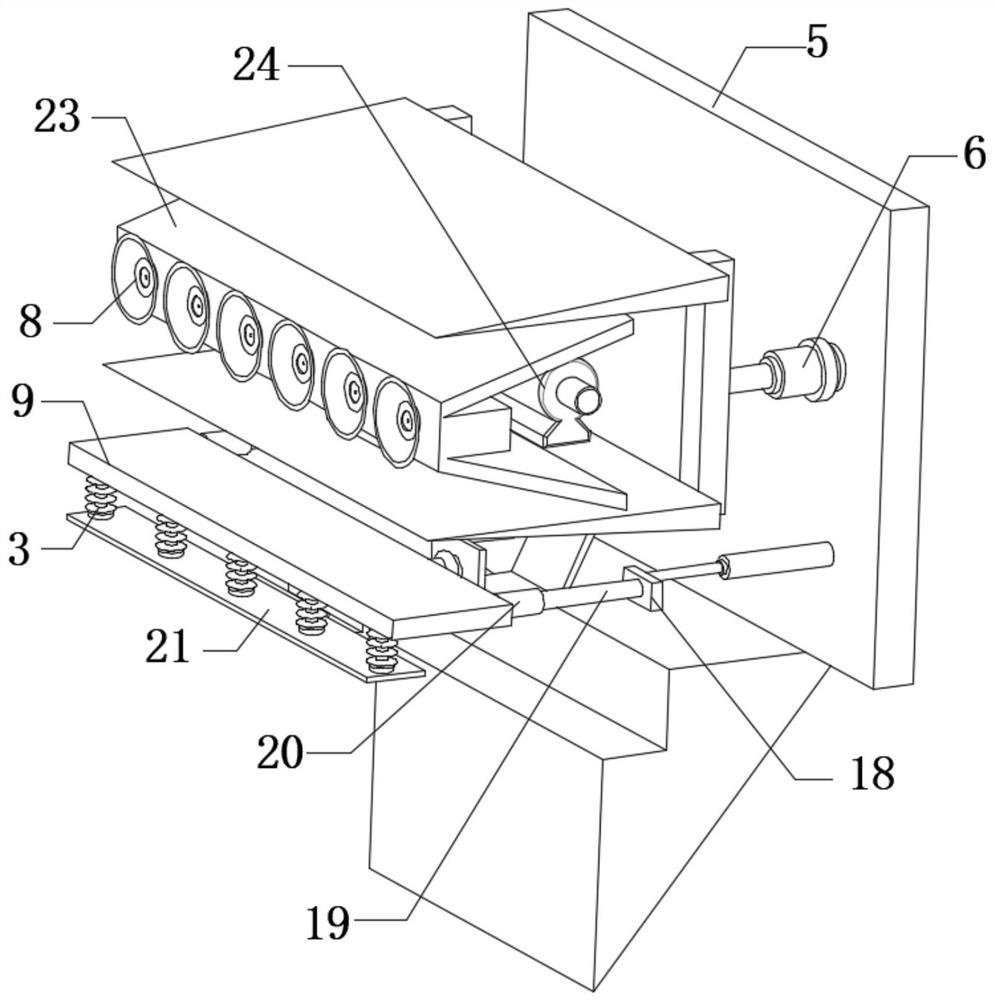

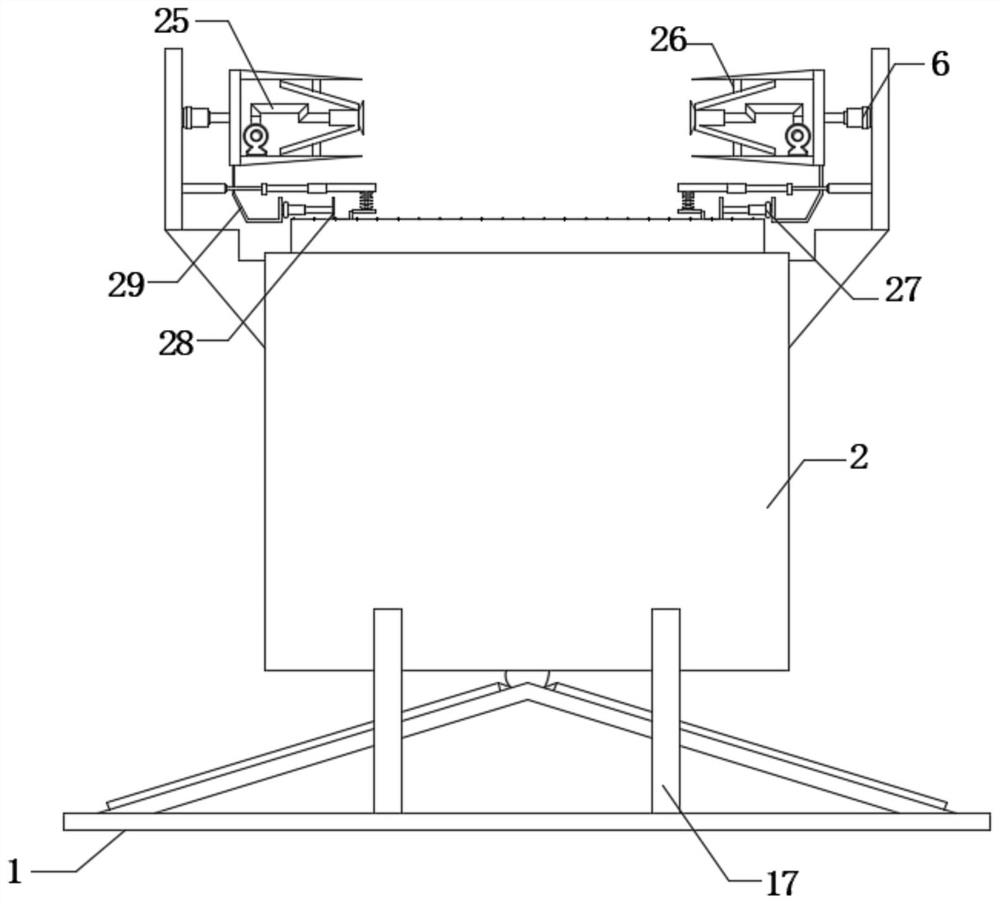

[0035] refer to Figure 1-7, a positioning fixture for making a 5G communication module and a method of use thereof, comprising a base 1 and a blanking frame 2, the outer walls of both sides of the blanking frame 2 are fixedly connected with supporting seats 14, and the tops of the two supporting seats 14 The outer walls are fixedly connected with side plates 5, and the outer walls of the opposite sides of the two side plates 5 are fixedly connected with two hydraulic cylinders 6, and the outer walls of each hydraulic cylinder 6 are fix...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap