Tension pay-off device

A pay-off device and tension technology, which is applied in the field of tension pay-off devices, can solve problems such as high cost and constant tension pay-off obstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

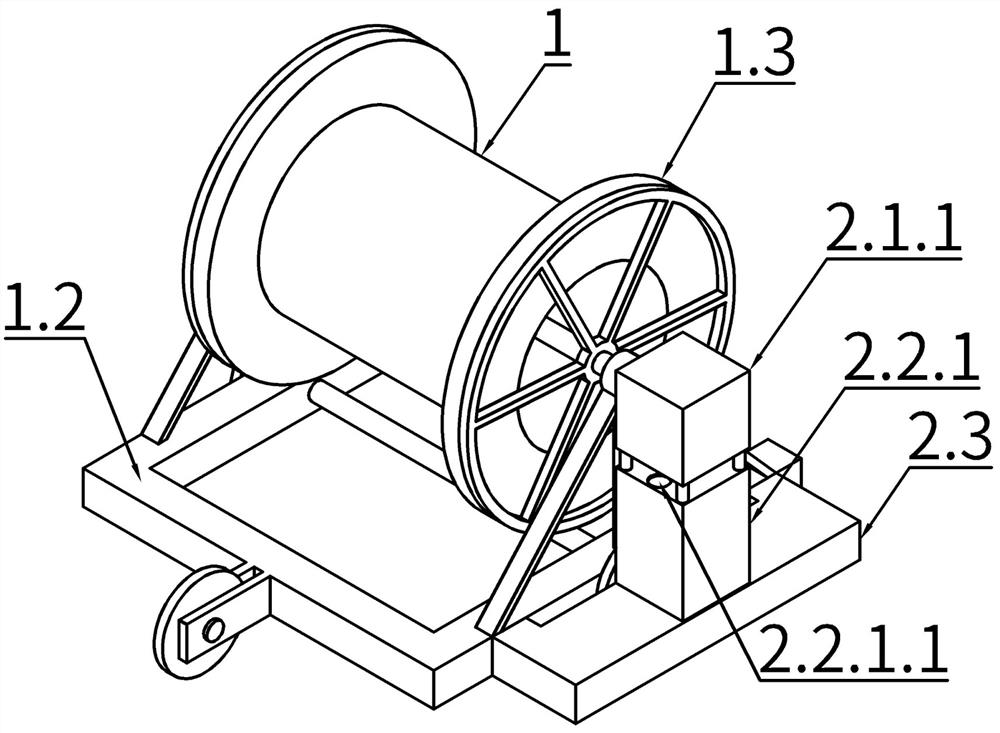

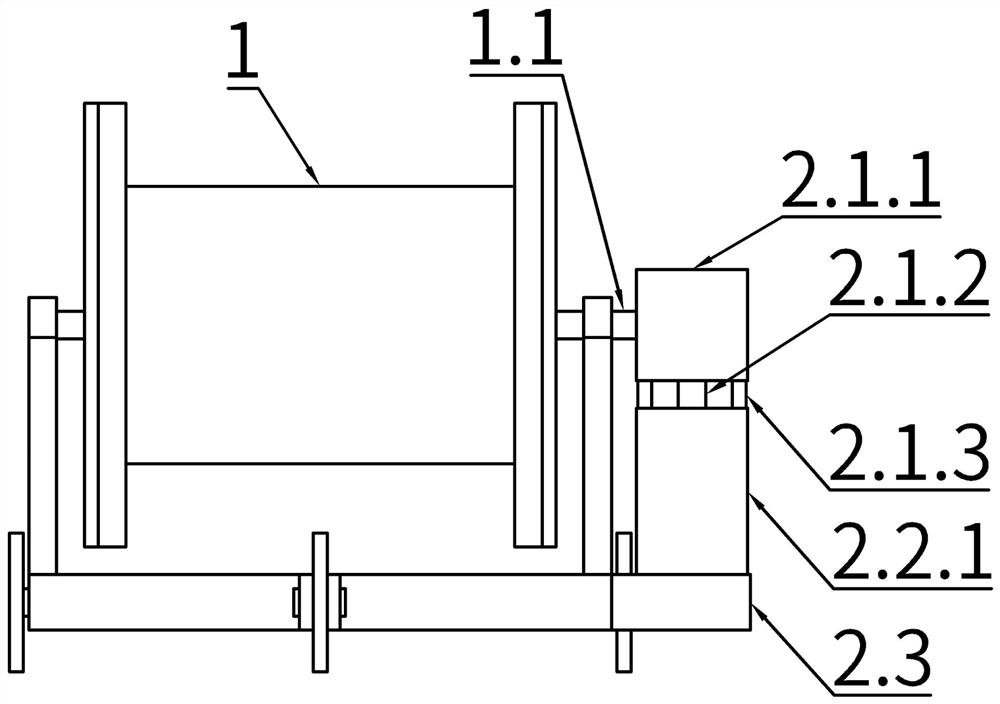

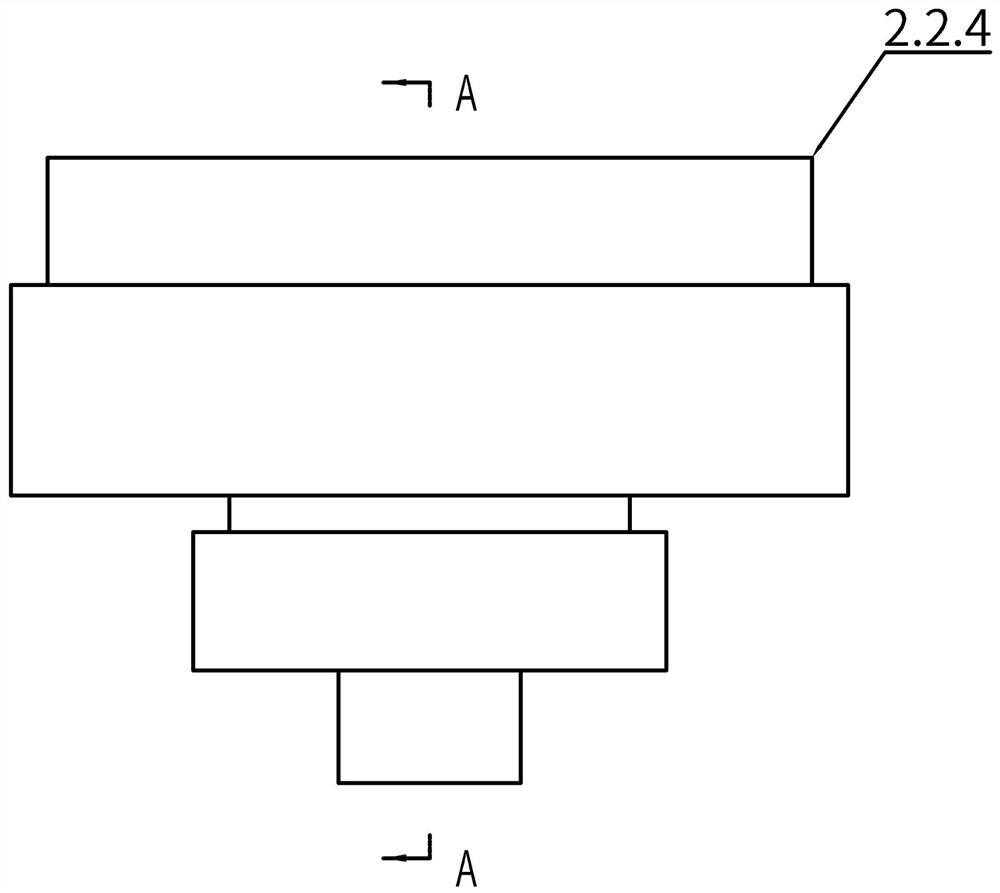

[0033] Such as Figure 1-12 shown. A tension pay-off device, comprising a pay-off barrel 1 placed on a vehicle frame 1.2, the pay-off barrel 1 is provided with a pay-off barrel rotation shaft 1.1 and a pay-off barrel rim 1.3 which rotate together with the pay-off barrel 1, and a There are buffer force generating device, support seat 2.3, and brake device (not shown in the figure); support seat 2.3 is used to support and fix the buffer force generating device; Apply a buffer force to the rotation of the pay-off drum rotating shaft 1.1; the buffer force generating device includes a buffer force generating device shell 2.2.1, and the buffer force generating device shell 2.2.1 is also provided with an air pressure through hole 2.2.1.1; the buffer force generating device Inside the casing 2.2.1, there is a buffer force generating cylinder 2.2.4 and a buffer force generating device piston 2.2.3 that can move axially along the buffer force generating cylinder 2.2.4, and the buffer f...

Embodiment 2

[0047] The difference between this embodiment and Embodiment 1 is that the power steering device support column 2.1.3 is no longer provided on the top of the buffer force generating device housing 2.2.1, but the power steering device housing is fixed on the vehicle frame 1.2 The end of the output shaft 2.1.2 of the power steering device is connected to the heavy block 2.1.4 through a rope, and the heavy block 2.1.4 is connected to the rotating part 2.2.2 of the buffer force generating device through a rope; there are 4 buffer force generating units, Correspondingly, the buffer force generating device piston 2.2.3 is also provided with first to fourth piston plates, thus, in H 1 = a, Z 2 = b, Z 3 = c, we know that H 2 = a, H 3 =a+b,H 4 =a+b+c. However, according to the structure disclosed in this embodiment, those skilled in the art can still easily know that the device disclosed in this embodiment can provide buffer force and thus relatively stable tension.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com