Liquid crystal composition, liquid crystal display element, and liquid crystal display

A technology of liquid crystal composition and compound, applied in the direction of liquid crystal materials, instruments, chemical instruments and methods, etc., to achieve the effects of suitable pretilt angle, high charge retention rate, high polymerization rate and conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

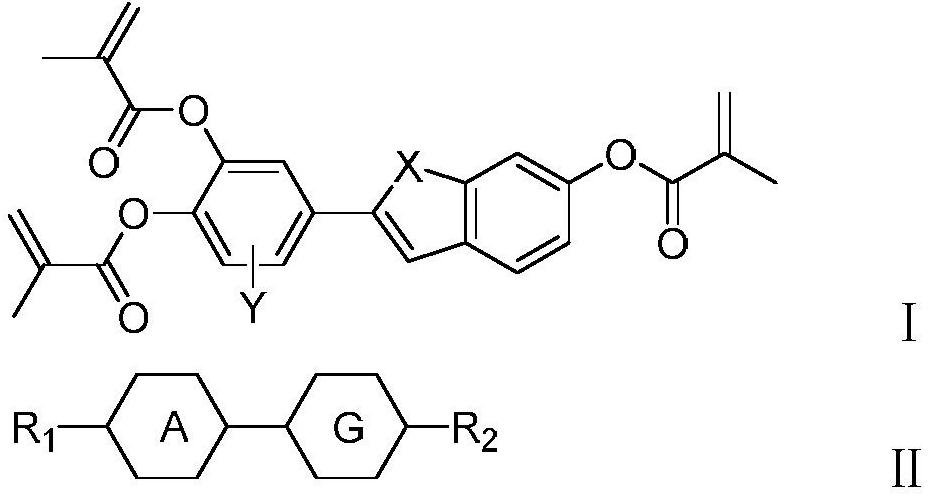

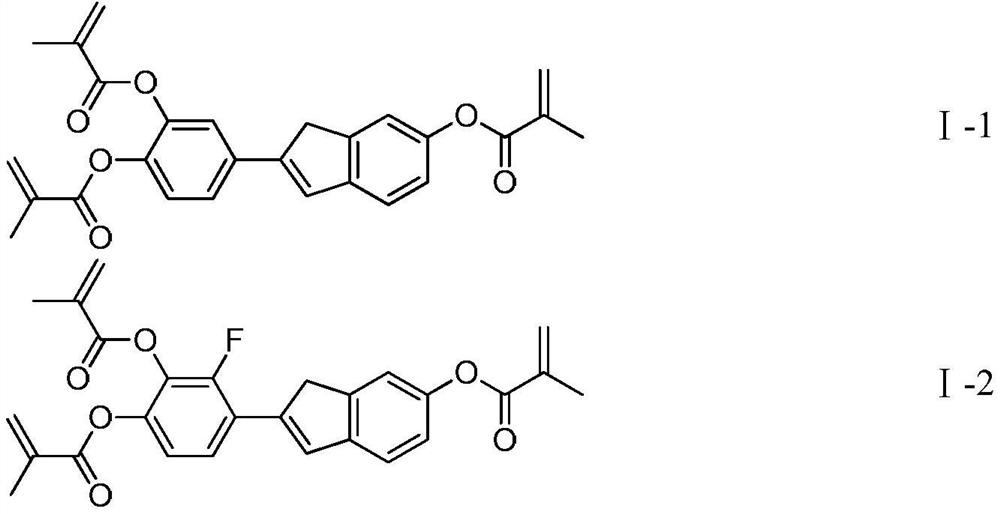

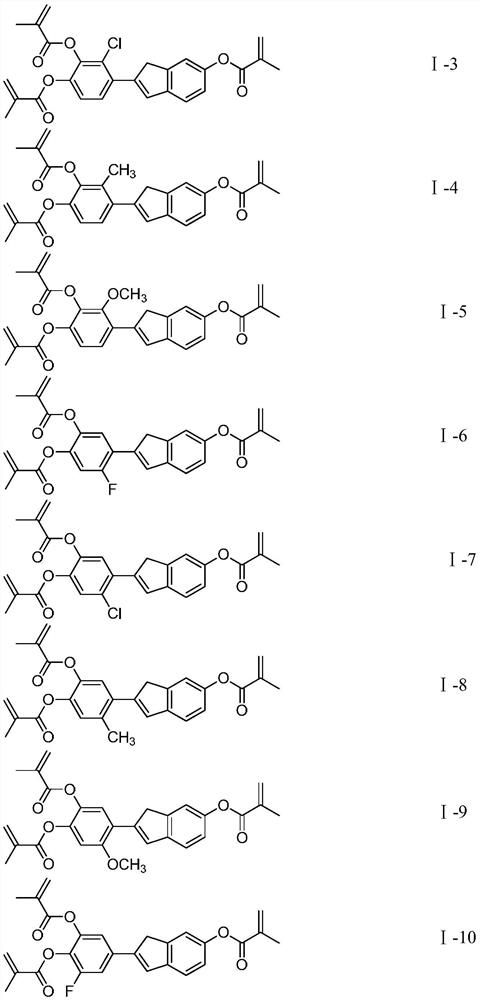

Method used

Image

Examples

preparation example Construction

[0085] The preparation method of the liquid crystal display of the present invention, and those skilled in the art can prepare a suitable method according to common sense in the art. An example of a method of preparing a liquid crystal display of the present invention, for example, a method of preparation of the following steps:

[0086] The coordinate material is uniformly applied to the surface of the first substrate and the second substrate, and the alignment material can be used to heat curing, and the heating temperature is 210 to 250 ° C, form an alignment layer;

[0087] The spacer spacer is distributed in the second substrate surface, and the box gel is coated along the edge of the first substrate, and solidified at 100 ° C to 150 ° C;

[0088] The first substrate and the second substrate are disposed relatively, and the structure having a sandwich space is formed in combination;

[0089] The liquid crystal composition is injected into the interlayer space between the firs...

Embodiment

[0092] The present invention will be described in connection with the preferred embodiments in connection with the preferred embodiments. Warr arts in the art will appreciate that the described herein is illustrative and not limiting, and the scope of the invention should not be limited.

[0093]In the present invention, the preparation method is a conventional method, and the raw materials used may be obtained from the disclosed business pathway, and the percentage of the material is referred to as the mass percentage, the temperature is also known as the degree of degrees Celsius (° C). For the liquid crystal monomer, the specific significance and test conditions of other symbols are as follows:

[0094] CP represents a liquid crystal clear point (° C), DSC quantitative method test;

[0095] Δn represents optical anisotropy, n o Refractive index for ordinary light, N e In the refractive index of non-ordinary light, the test conditions are 25 ± 2 ° C, 589 nm, and Abeth Reflector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com