Liquid crystal compound and liquid crystal medium containing liquid crystal compound

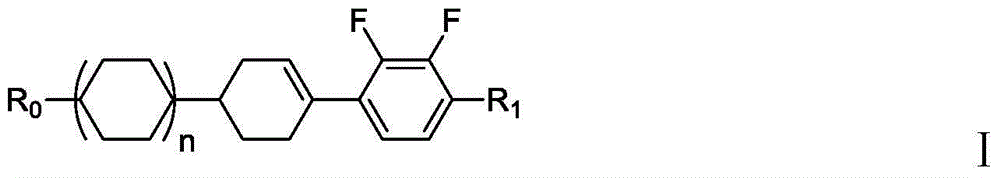

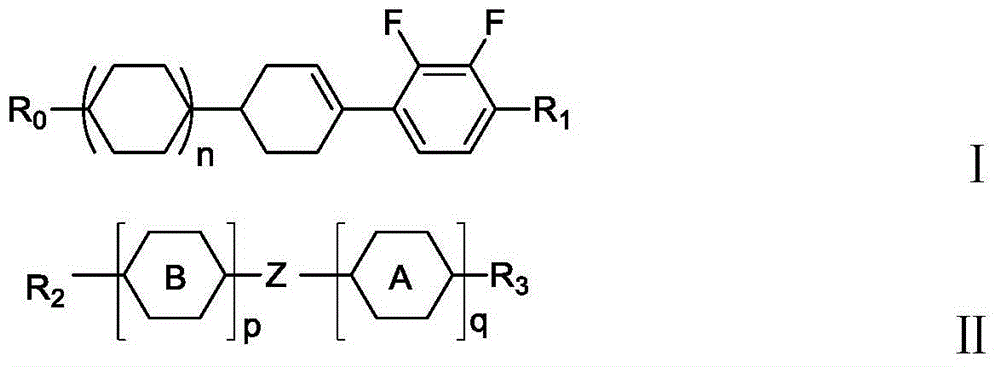

A liquid crystal compound and liquid crystal medium technology, applied in liquid crystal materials, organic chemistry, chemical instruments and methods, etc., can solve the problems of low contrast, narrow viewing angle, and small wavelength dependence of birefringent liquid crystal layer, and achieve a large K value. , the effect of low rotational viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

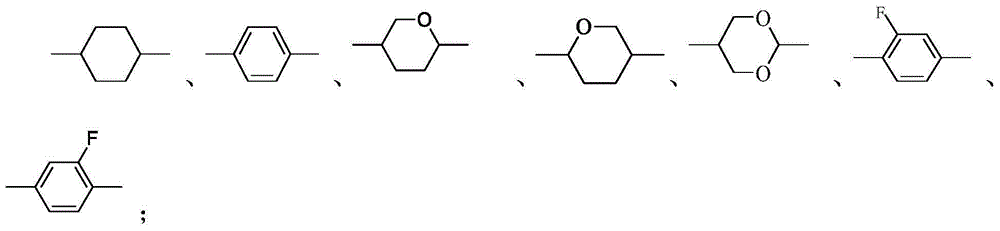

Method used

Image

Examples

Embodiment 1

[0078]

[0079] step 1

[0080]

[0081] Dissolve 16.7g (0.05mol) (1-b) in 150ml ether, add 0.06mol of cyclopropylmagnesium bromide dropwise at below 0°C, hydrolyze with ammonium chloride aqueous solution for 1 hour, extract, pass through a silica gel column, and weigh Purified by crystallization to obtain 8.2 g of (1-c).

[0082] step 2

[0083]

[0084] (1-c) 8.2g (0.022mol) was dissolved in 50ml of dichloromethane, 0.05mol triethylsilane and 0.05mol boron trifluoride ether were added dropwise at -70°C, the temperature was raised to 0°C, and conventional treatment gave 6.8 g(1-a). Gc: 99.9%

[0085] The same synthetic method, obtain the following liquid crystal compound

[0086]

Embodiment 2

[0088]

[0089] step 1

[0090]

[0091] Dissolve 18.1g (0.05mol) (2-b) in 150ml ether, add 0.06mol cyclopropylmagnesium bromide dropwise at below 0°C, hydrolyze with ammonium chloride aqueous solution for 1 hour after adding, extract, pass through a silica gel column, and weigh Purification by crystallization gave (2-c) 14g.

[0092] step 2

[0093]

[0094] (2-c) 14g (0.035mol) was dissolved in 150ml of dichloromethane, 0.07mol triethylsilane and 0.07mol boron trifluoride ether were added dropwise at -70°C, the temperature was raised to 0°C, and 9.5g was obtained (2-a). Gc: 99.91%

[0095] The same synthetic method, obtain the following liquid crystal compound

[0096]

[0097]

Embodiment 3

[0099]

[0100] Dissolve 18.4g (0.1mol) (3-b) in 100ml THF, add 0.11mol butyllithium dropwise at -70°C in a nitrogen atmosphere, and then add 0.105mol 4-propylbicyclic ketone dropwise after the addition is complete. Rising to room temperature, conventional processing, to obtain (3-a) 31g, Gc: 99.91%

[0101] The component distribution ratio and performance parameters of the liquid crystal composition of Table 1 Example 4

[0102]

[0103]

[0104] The component ratio of the liquid crystal composition of table 2 embodiment 5 and performance parameter thereof

[0105]

[0106]

[0107] The component distribution ratio and performance parameters of the liquid crystal composition of Table 3 Example 6

[0108]

[0109]

[0110] The component ratio of the liquid crystal composition of Table 4 Example 7 and its performance parameters

[0111]

[0112]

[0113] The formula of liquid crystal composition of table 5 embodiment 8 and test performance parameter t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com