Anti-corrosion electrode shell of steel shell button cell, preparation method of anti-corrosion electrode shell, steel shell button cell and application of steel shell button cell

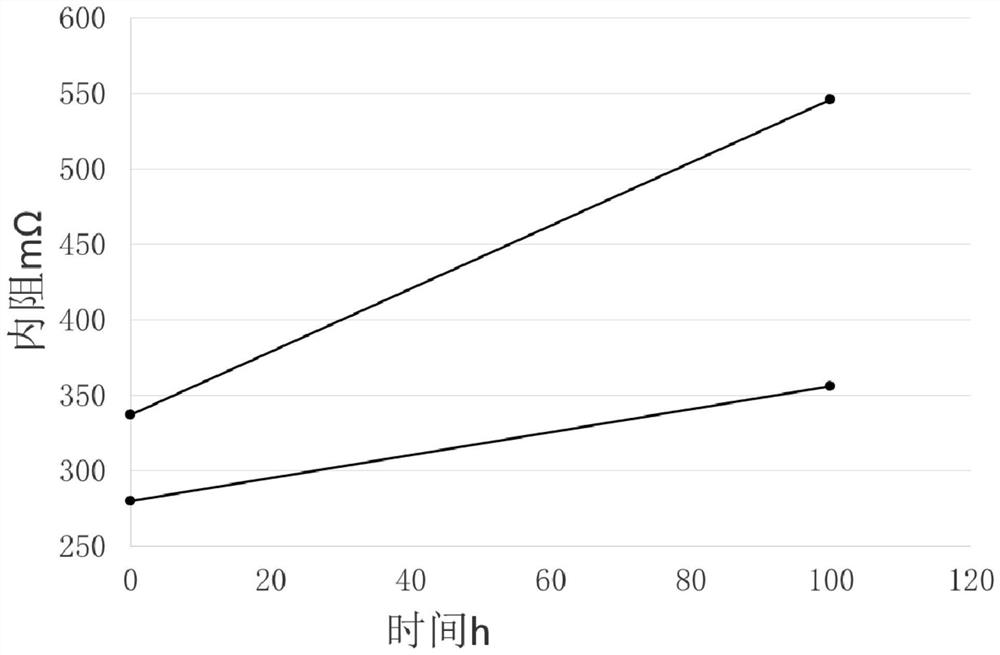

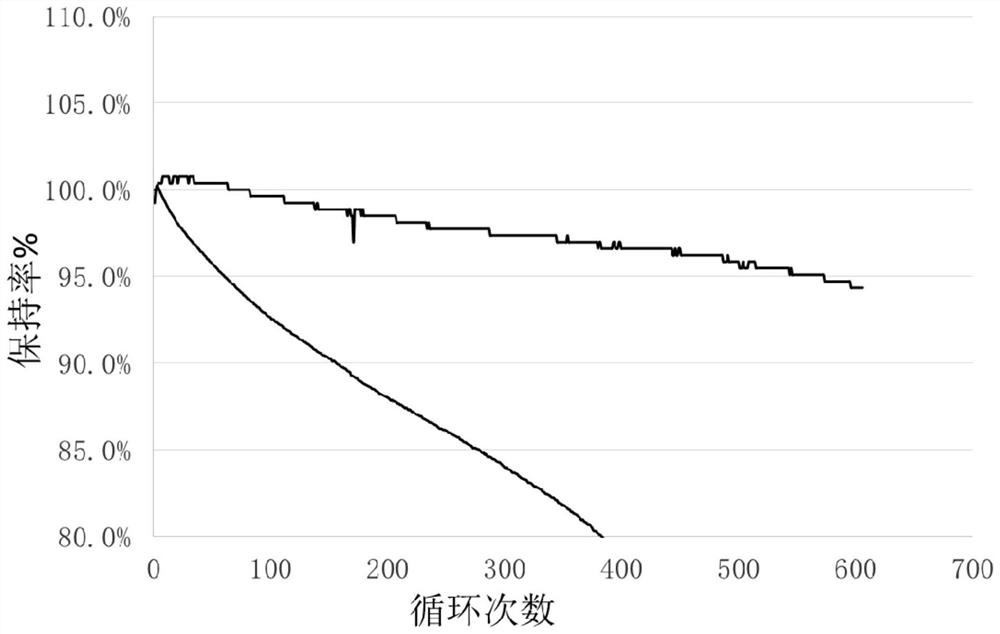

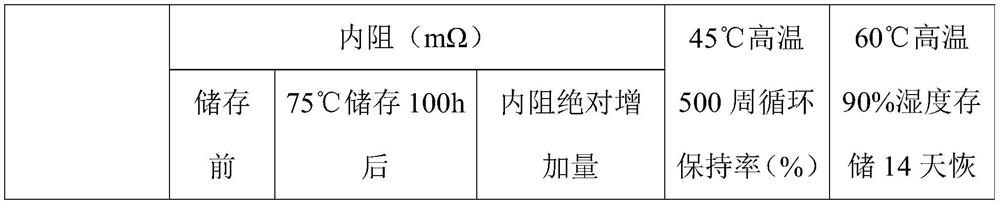

A button battery and anti-corrosion technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of blackening of the positive and negative steel shells, low potential of the negative steel shells, and corrosion of the positive and negative shells. The effect of preventing corrosion, improving K value, and reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment provides an anti-corrosion electrode case of a steel case button battery, the anti-corrosion electrode case includes a stainless steel substrate (304 steel) and a 70 μm thick nickel coating coated on the inner surface of the stainless steel substrate.

[0052] This embodiment also provides a preparation method for the anti-corrosion electrode case of the steel case button battery, the preparation method comprising:

[0053] The stainless steel substrate is clamped in the splint, only the inner surface of the stainless steel substrate is exposed, and a nickel layer is formed on the inner surface of the stainless steel substrate by electroplating. The electroplating solution used for electroplating to form the nickel layer includes nickel sulfate, magnesium sulfate, and sulfuric acid. Sodium, boric acid and sodium chloride, and the pH value of the electroplating solution is 5.6, and the current density in the electroplating process is 1.5A / dm 2 , Electropl...

Embodiment 2

[0055] This embodiment provides an anti-corrosion electrode case of a steel case button battery, the anti-corrosion electrode case includes a stainless steel base (304 steel) and a 63 μm thick aluminum coating coated on the inner surface of the stainless steel base.

[0056] This embodiment also provides a preparation method for the anti-corrosion electrode case of the steel case button battery, the preparation method comprising:

[0057] The stainless steel substrate is clamped in the splint, only the inner surface of the stainless steel substrate is exposed, and an aluminum coating is formed on the inner surface of the stainless steel substrate by electroplating. The electroplating solution used for electroplating to form the aluminum coating includes 65% molar content of After mixing urea and aluminum chloride with a content of 40%, heat at 65°C for 3h, then add the same volume of amide, stir and filter the composition, and the pH value of the electroplating solution is 7.5,...

Embodiment 3

[0059] This embodiment provides an anti-corrosion electrode case of a steel case button battery, the anti-corrosion electrode case includes a stainless steel substrate (304 steel) and a 150 μm thick zinc coating coated on the inner surface of the stainless steel substrate.

[0060] This embodiment also provides a preparation method for the anti-corrosion electrode case of the steel case button battery, the preparation method comprising:

[0061] The stainless steel substrate is clamped in the splint, only the inner surface of the stainless steel substrate is exposed, and a silicon carbide coating is formed on the inner surface of the stainless steel substrate by electroplating. The electroplating solution used for electroplating to form the zinc coating includes a sulfuric acid solution containing zinc 65g / L, potassium 200g / L, boric acid 35g / L, and the pH value of the electroplating solution is 5.2, and the current density in the electroplating process is 1-4A / dm 2 , Electropl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com