Sealing detection device and method

A sealing detection and sealing technology, applied in the field of sealing detection devices, can solve problems such as poor sealing detection effect of cup plating equipment, improve process stability and utilization rate, and avoid missed detection and false detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

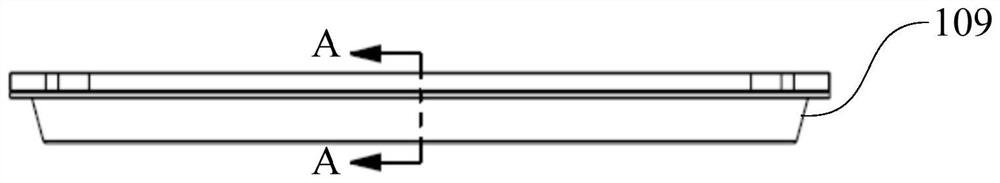

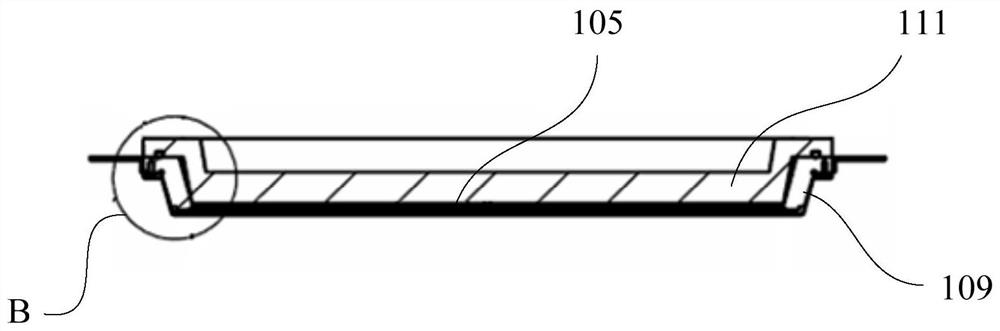

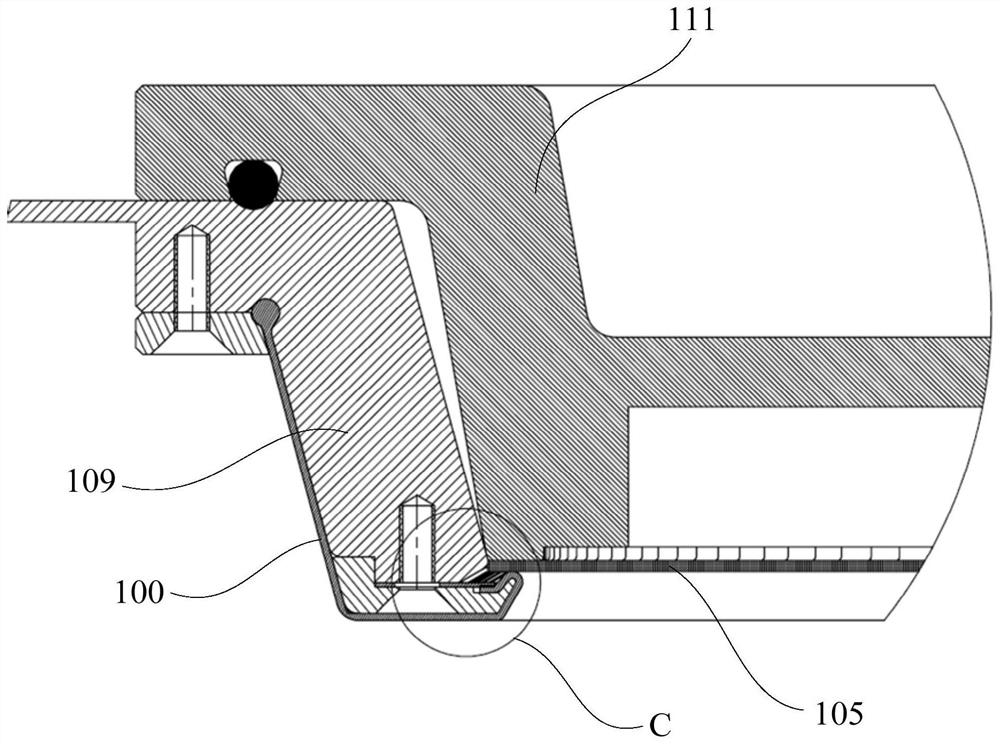

[0046] see Figure 1 to Figure 5 , the present embodiment provides a sealing detection device for detecting the sealing of the electroplating equipment seal 100, including:

[0047] The first electrode 101, the second electrode 102, the current detection module 103 and the judgment module 104;

[0048] Wherein, the current detection module 103 for detecting the current value is respectively connected to the first electrode 101 and the second electrode 102 through wires, and the judgment module 104 is connected to the current detection module 103 and obtains the current value ;

[0049] The surface of the substrate 105 clamped by the electroplating equipment is divided into a first area and a second area by the sealing member 100; the first electrode 101 is in contact with and connected to the first area, and the second electrode 102 is electroplated Liquid 106 connects the second region to form a detection loop between the first electrode 101, the substrate 105, the second e...

Embodiment 2

[0059] see Figure 1 to Figure 5 , the present embodiment provides a sealing detection method, comprising the following steps:

[0060] 1) The substrate 105 is loaded on the electroplating equipment, and the seal 100 of the electroplating equipment separates the surface of the substrate 105 into a first area not in contact with the electroplating solution 106 and a second area in contact with the electroplating solution 106;

[0061] 2) forming a detection circuit through the first region, the second region and the electroplating solution 106, energizing the detection circuit and detecting the actual current value of the detection circuit;

[0062] 3) Judging the tightness of the sealing member 100 to the electroplating solution 106 according to the actual current value.

[0063] In step 1), if Figure 1 to Figure 4 As shown, the substrate 105 is loaded on the electroplating equipment, and the seal 100 of the electroplating equipment separates the surface of the substrate 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com