Flow regeneration characteristic test system and test method

A technology of characteristic test and flow regeneration valve, applied in fluid pressure actuation system test, fluid pressure actuation device, mechanical equipment and other directions, can solve the problems of high cost and long test time, and achieve high cost, long test time, Time and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manners of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific implementation manners described here are only used to illustrate and explain the embodiments of the present invention, and are not intended to limit the embodiments of the present invention.

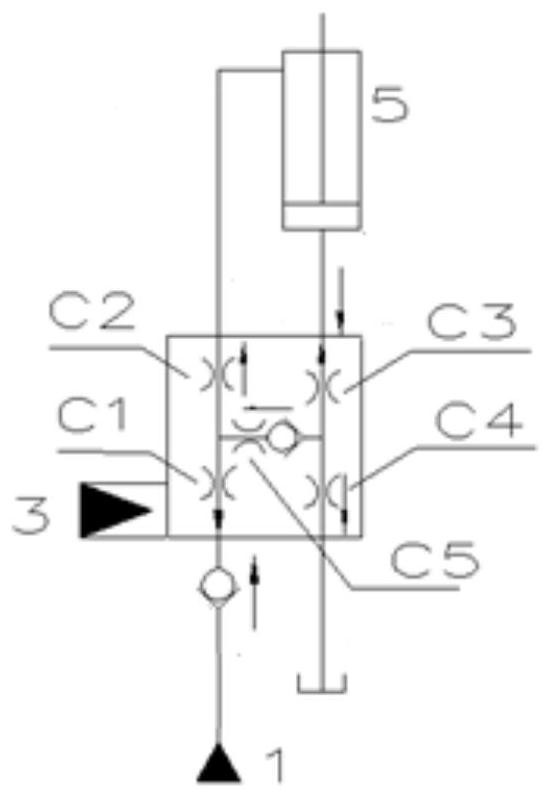

[0042] figure 1 It is the schematic diagram of the simplified flow regeneration characteristic test. Such as figure 1 As shown, the output flow q of the hydraulic pump 1 p1 All flows into the flow regeneration chamber, that is, the rod chamber of the loading cylinder 5, and then flows out from another chamber of the loading cylinder 5, that is, the rodless chamber of the loading cylinder 5, the flow rate q bAfter passing through the regeneration check valve in the flow regeneration valve 3, it is divided into two paths. One path flows into the rod cavity of the loading cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com