Quantitative evaluation method for hydration damage of shale based on acoustic wave velocity test

A technology for shale hydration and sonic wave velocity, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, processing of detected response signals, instruments, etc. The effect of ensuring test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

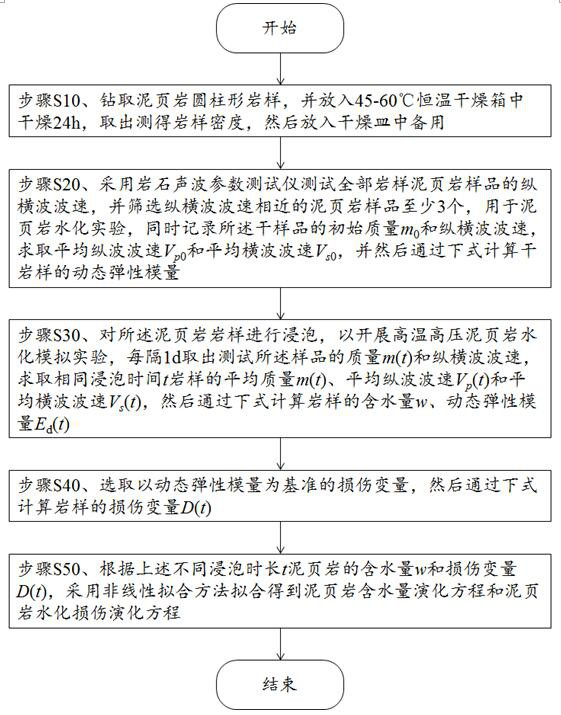

[0039] A method for quantitative evaluation of mud shale hydration damage based on acoustic wave velocity testing, comprising the following steps:

[0040] Step S10, drilling at least three shale cylindrical rock samples, and putting them into a constant temperature drying oven at 45-60°C to dry for 24 hours, taking them out after drying, measuring the density of the rock samples, and putting them into a drying dish for later use.

[0041] Step S20, using a rock acoustic wave parameter tester to test the longitudinal and shear wave velocities of all shale cylindrical rock samples; screen out at least 3 rock samples with similar longitudinal wave velocities and similar shear wave velocities to form a rock sample group for use in shale Hydration experiment; simultaneously record the mass, longitudinal wave velocity and shear wave velocity of each dry rock sample in the rock sample group, and calculate the initial average mass of the selected rock sample group m 0 , initial avera...

Embodiment 2

[0051] A method for quantitative evaluation of shale hydration damage based on acoustic wave velocity testing, comprising the following steps:

[0052] Step S10. Drill a cylindrical rock sample of mud shale, the size of which is Φ25×50mm, and put it in a constant temperature drying oven at 60°C for 24 hours. The average density of the rock sample is 2.75g / cm when taken out. 3 , and then put it in a desiccator for later use;

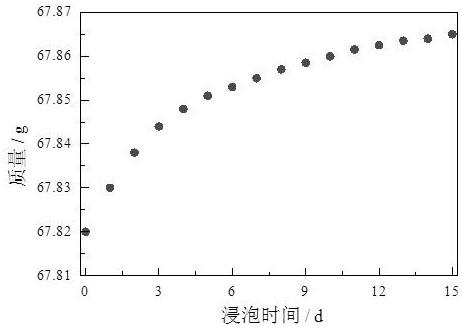

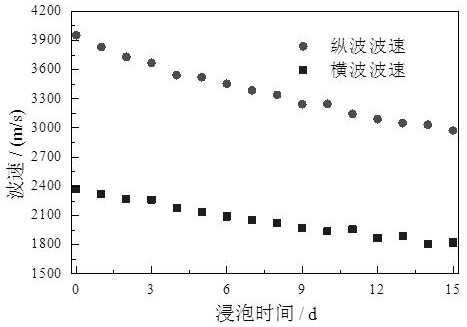

[0053] Step S20, using a rock acoustic wave parameter tester to test the longitudinal and transverse wave velocities of all the rock sample mud shale samples, screen out three mud shale samples with similar longitudinal and transverse wave velocities, and test the initial mass and longitudinal and transverse wave velocities of the three dry samples to find Take the initial average mass m 0 , the average longitudinal wave velocity V p0 is 3953m / s, the average shear wave velocity V s0 is 2372m / s, and then calculate the dynamic elastic modulus E of the dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com