Intelligent operation inspection system and method based on digital team electric power big data

A big data and electric power technology, applied in data processing applications, instruments, calculations, etc., can solve the problems of low efficiency of power equipment inspection work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

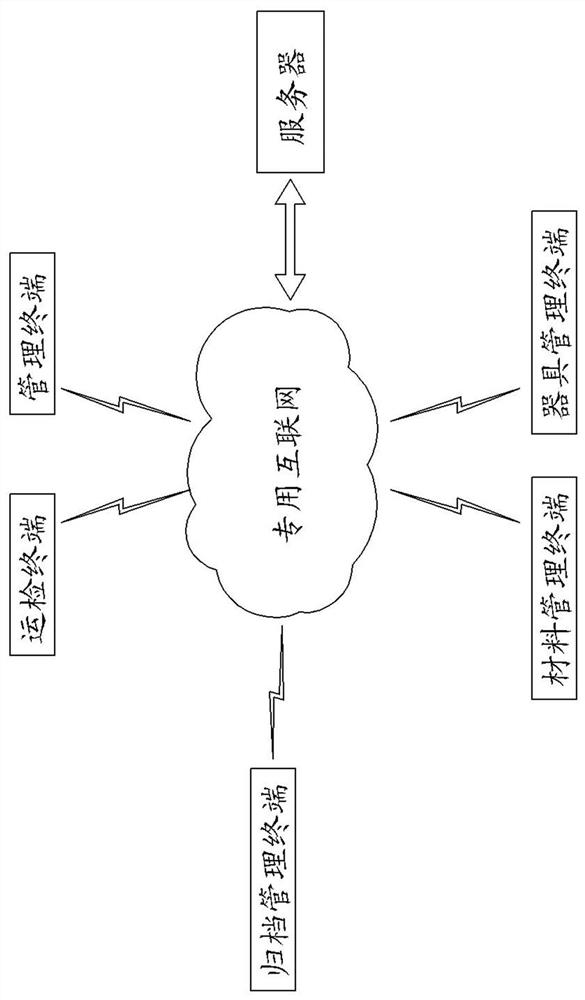

[0030] Such as figure 1 As shown, the present invention discloses a smart transportation inspection system based on digital team power big data, including a server, a management terminal for project managers, a transportation inspection terminal for transportation inspection personnel, and a material management personnel. Material management terminal for equipment management personnel, equipment management terminal for equipment management personnel and archive management terminal for archive management personnel, as well as work order dispatching module, work application module, material preparation module, equipment preparation module, vehicle dispatching module, maintenance execution module, data acquisition module, progress tracking module, report generation module and auditing and archiving module, the management terminal, transportation inspection terminal, material management terminal, appliance management terminal and filing management terminal are all mobile terminals,...

Embodiment 2

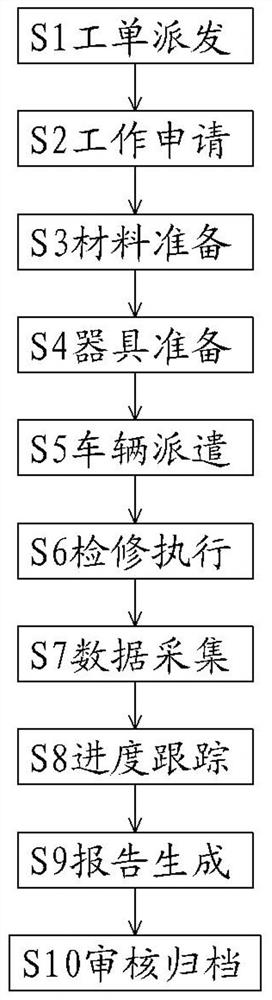

[0043] Such as figure 2 As shown, the present invention discloses a smart transportation inspection method based on digital team power big data, based on the server in Embodiment 1, the management terminal used by the project management personnel, the transportation inspection terminal used by the transportation inspection personnel, and the The material management terminal used by material management personnel, the equipment management terminal used by equipment management personnel and the archive management terminal used by archive management personnel include the following steps:

[0044] S1 work order distribution

[0045] When creating a task, the server generates a work order according to the planned task, the missing task, the carrying capacity of the team and the dynamic portrait of the personnel.

[0046] S2 job application

[0047] The server sends the power outage application and work order to the management terminal and obtains authorization.

[0048] S3 mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com