Thermoelectric refrigerator, preparation method of thermoelectric refrigerator and electronic equipment

A thermoelectric cooler and thermoelectric technology, applied in the field of electronics, can solve the problems of complex manufacturing process and high cost of aluminum nitride ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

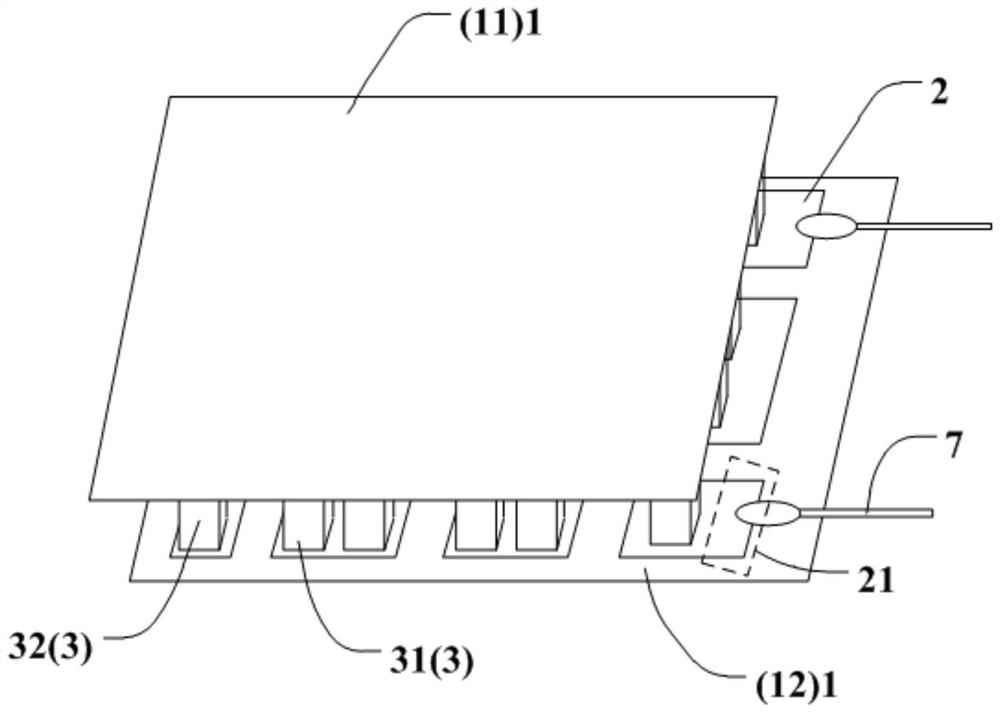

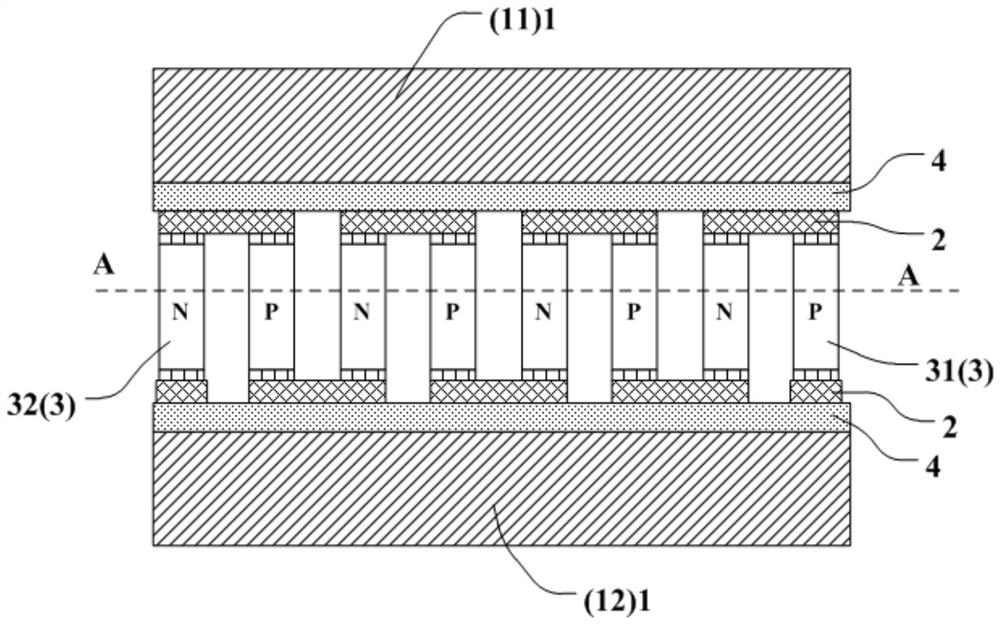

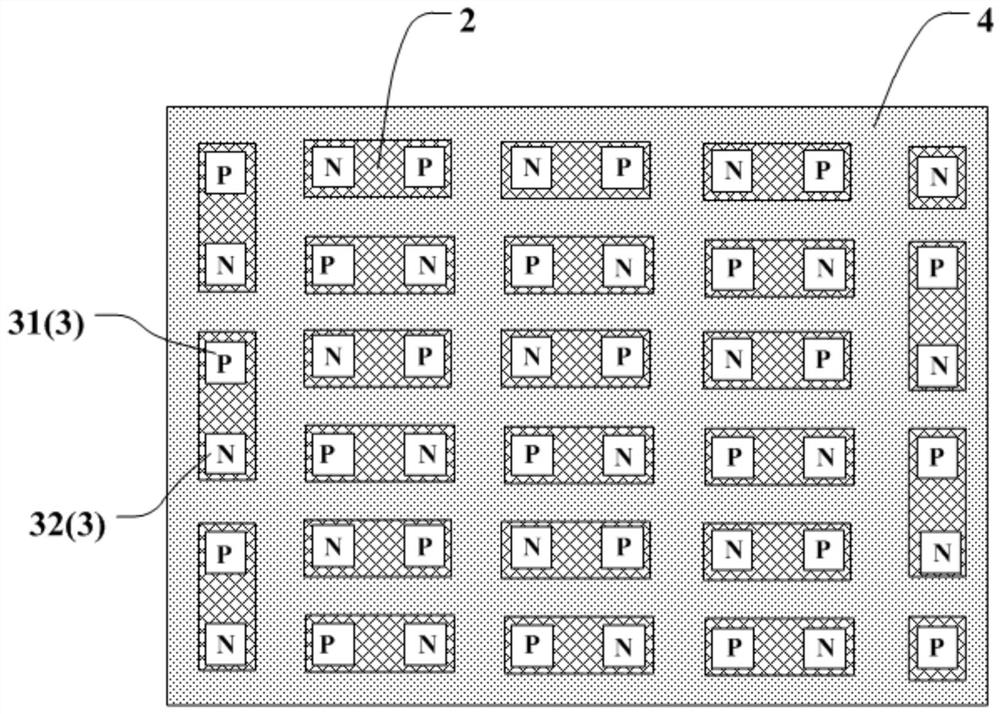

[0034] The thermoelectric refrigerator provided by the embodiment of the present invention can be applied to various electronic devices, and is used to control the temperature of the temperature-controlled structure in the electronic device, so that the temperature of the temperature-controlled structure can be kept at the set temperature, so as to improve the temperature of the temperature-controlled structure. Structural performance and reliability. The cost of the thermoelectric cooler in the prior art is relatively high, and the cost of the substrate accounts for 20% to 30% of the manufacturing cost of the high-performance thermoelectric cooler. Therefore, the cost of the substrate can be reduced to reduce the manufacturing cost of the thermoelectric cooler, and It is necessary to maintain a high thermal conductivity of the substrate. Therefore, the present invention provides a thermoelectric cooler, a preparation method of the thermoelectric cooler and electronic equipmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com