Stator winding structure and electric machine comprising stator winding structure

A stator winding and winding technology, applied in the shape/style/structure of winding conductors, windings, electromechanical devices, etc., can solve the problems of electromagnetic coupling uneven current circulation, etc., to reduce current circulation, improve heat dissipation capacity, and reduce heat radiation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

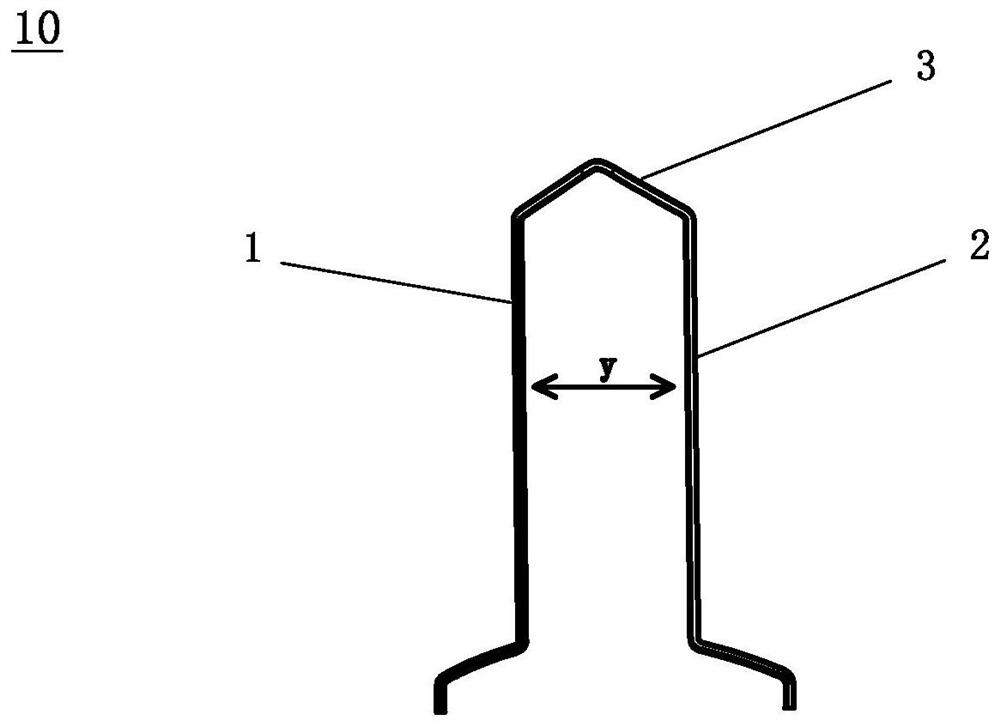

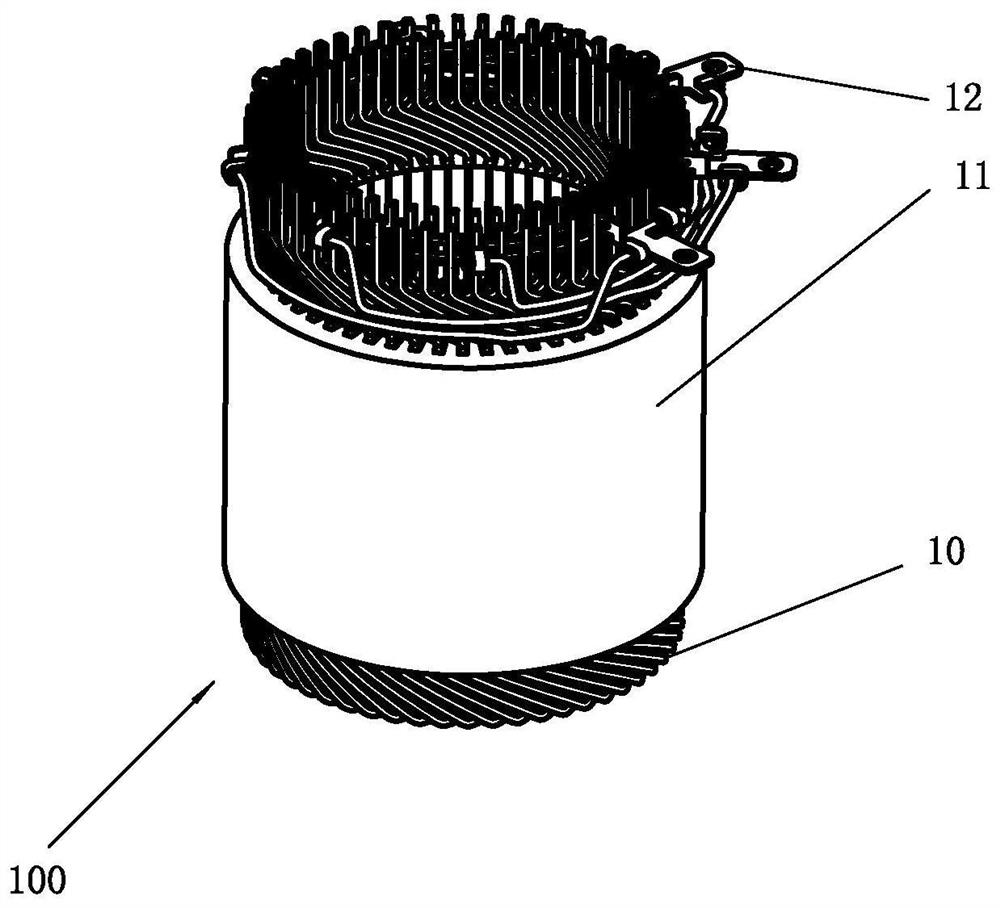

[0147] In the three-phase AC motor of this example, the stator includes a stator core 11 and a stator winding structure 100 . The stator core 11 has a plurality of slots distributed in the circumferential direction. The stator winding structure 100 is composed of a plurality of U-shaped flat copper wires 10 .

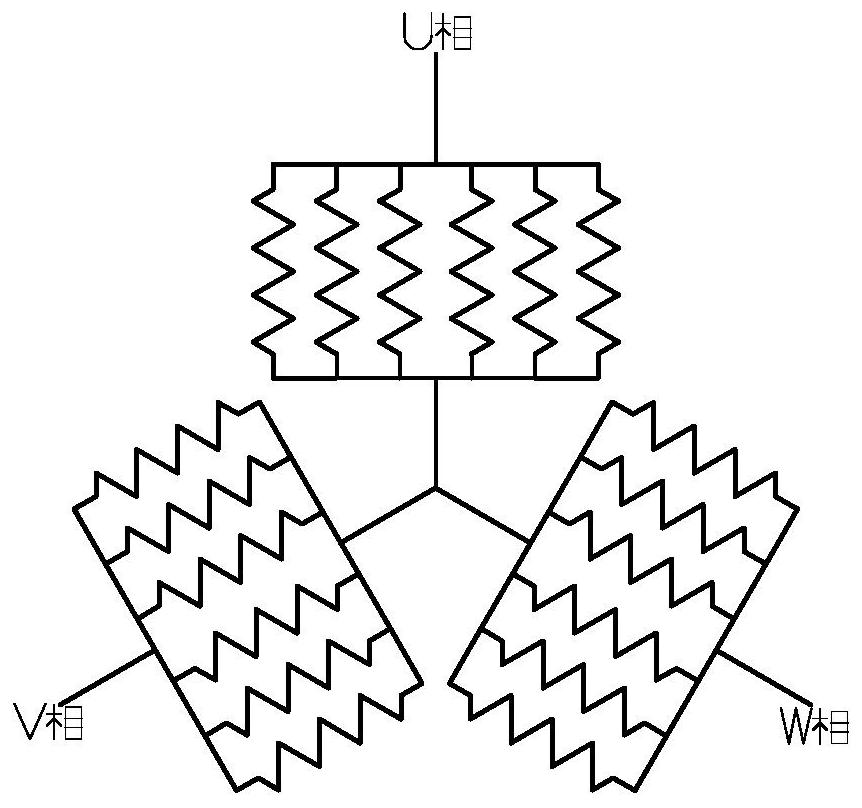

[0148] Three-phase (U, V and W phases) outgoing wires in the stator are arranged at the welding ends of the U-shaped flat copper wires 10 of the stator winding structure 100 . Accordingly, the deflector 12 (eg Figures 7A-7C Its internal wiring is shown in detail) is also arranged at the welding end for the outgoing wires of each phase. The stator of the first embodiment is as Figure 3-4 shown.

[0149] like Figure 5-6 , Figures 8A-8F as well as Figures 9A-9F As shown, the perspective view, the wiring structure diagram and the developed view from the U-shaped end (the first side) of the six parallel-wound branches of the U-phase winding 100U of the first embo...

Embodiment 2

[0172] In the three-phase AC motor of this example, the stator includes a stator core 11 and a stator winding structure 100 . The stator core 11 has a plurality of slots distributed in the circumferential direction. The stator winding structure 100 is composed of a plurality of U-shaped flat copper wires 10 .

[0173] Three-phase (U, V and W phases) outgoing wires in the stator are arranged at the U-shaped ends of the U-shaped flat copper wires 10 of the stator winding structure 100 . Accordingly, the deflector 12 (eg Figures 7A-7C Its internal wiring is shown in detail in ) is also arranged at the U-shaped end for the outgoing wires of each phase. The stator of the second embodiment is as Figure 10-11 shown.

[0174] like Figure 12-13 , Figures 14A-14F as well as Figures 15A-15F As shown, the perspective view, the wiring structure diagram and the developed view from the U-shaped end (the first side) of the six parallel-wound branches of the U-phase winding 100U of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com