Efficient energy-saving screw and extruder

An energy-saving extruder technology, applied in the field of extruders, can solve the problems of high temperature in the compression section and metering section, high shear heat and friction heat, etc., and achieve torque reduction, temperature balance, and fast feeding and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

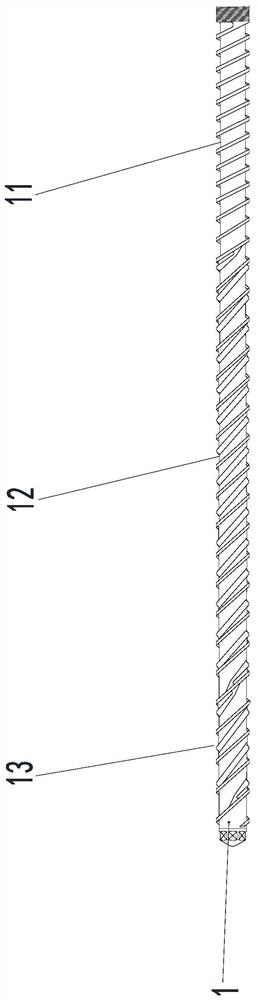

[0032] see Figure 1-2 : A high-efficiency and energy-saving screw rod, comprising a first screw body 1, the inside of the first screw body 1 is set as a hollow structure, and an easily vaporized substance is arranged in the hollow structure for thermal cycle.

[0033] In this embodiment, under the condition that the strength of the screw is sufficient, the screw is set as a hollow structure, and an appropriate amount of easy-to-vaporize substance is added in the airtight hollow structure. When the screw is working, it is vaporized when it is heated, and the heat from all parts of the screw is conducted. It is conducive to the uniform heat of the screw, and in addition, it condenses when it is cold, so as to circulate, so as to achieve the purpose of heat circulation.

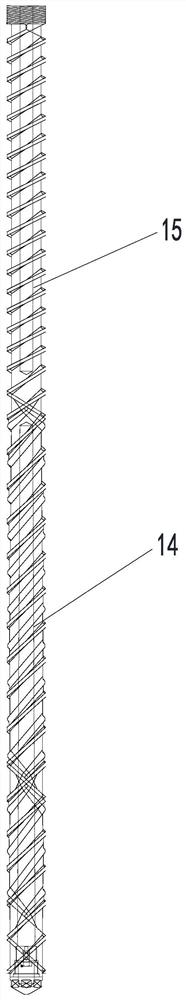

[0034] In a specific example, the hollow structure includes the first tapered hole hollow shaft structure 14 of the first screw compression section 12 and the first screw homogenization section 13 and the first...

Embodiment 2

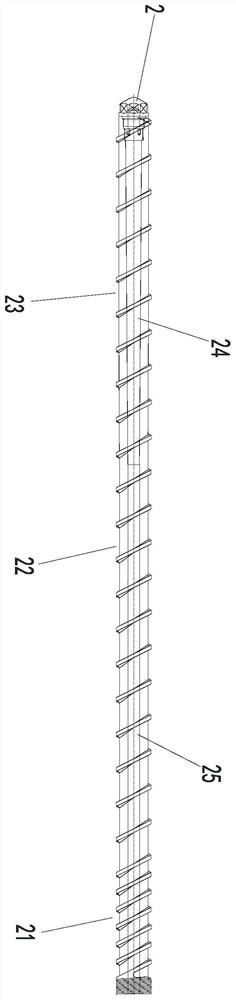

[0042] see image 3: a high-efficiency energy-saving screw, comprising a second screw body 2, the inside of the second screw body 2 is set as a hollow structure, and the hollow structure includes a second screw compression section 22 and a second screw homogenization section 23 The conical hole hollow shaft structure 24 and the second cylindrical hole hollow shaft structure 25 of the second screw feeding section 21 , the second conical hole hollow shaft structure 24 communicates with the second cylindrical hole hollow shaft structure 25 and is not sealed.

[0043] In this embodiment, on the premise of ensuring the strength of the screw, the hollow shaft structure of the second tapered hole communicates with the hollow shaft structure of the second cylindrical hole. When the screw is working, it generates internal circulation with the external air, so that each section of the second screw body The temperature is more controllable.

[0044] Specifically, the second screw body 2...

Embodiment 3

[0049] For this purpose, see image 3 : The present embodiment also provides an extruder, which includes the above-mentioned high-efficiency and energy-saving screw.

[0050] The extruder of this embodiment has the same advantages as the above-mentioned high-efficiency and energy-saving screw compared with the prior art, and will not be repeated here.

[0051] Specifically, the extruder is sequentially provided with a feeding device 3, a screw feeding section in the barrel 4, a screw compression section, a screw homogenizing section and a machine head 5 along the material input direction, the screw feeding section, The screw compression section and the screw homogenization section are each equipped with a heating and cooling mechanism 6 and a temperature monitoring device 7 .

[0052] The screw feeding section, the screw compression section, and the screw homogenizing section of this embodiment can all monitor the temperature through the corresponding temperature monitoring d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com