Making method combining wax printing process and real silk degumming process

A production method and degumming technology, applied in the field of batik technology, can solve the problems of monotonous picture texture, easy wear and tear of paintings, and short use time, and achieve the effect of strong three-dimensional effect, not easy to fade, and not easy to change color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Degumming the silk fabric in boiling water with an alkaline pH value of 7 for 15 minutes;

[0034] Combine 10 parts of water at 80°C, 2 parts of salt, 3 parts of alkali, 3 parts of soda and 5 parts of urea for batik dyeing;

[0035] fade wax;

[0036] All sealing wax;

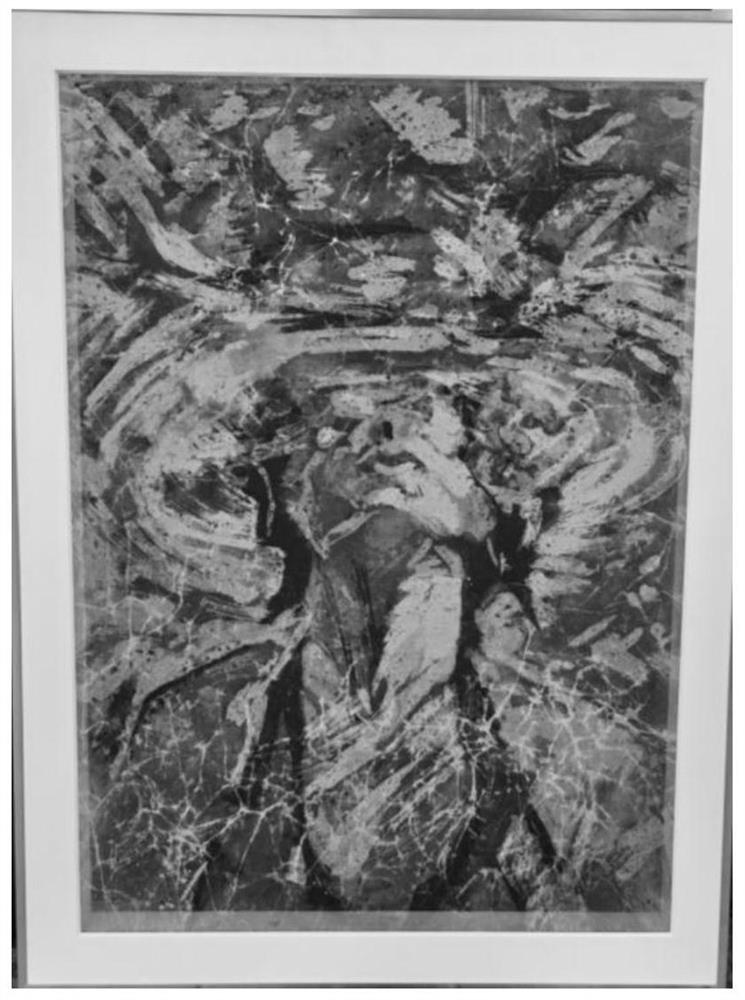

[0037] Refer to the parts that need to make watermarks image 3 As shown in the comparison picture of the silk fabric before dyeing; fold the part that needs to be watered to break the wax;

[0038] The temperature is controlled at 25°C, adjusted with 84 disinfectant and water at a ratio of 1:5, soaked for 30 minutes to achieve degumming, iron the fabric after degumming, and mount.

Embodiment 2

[0040] Degumming the silk fabric in boiling water with an alkaline pH value of 7 for 20 minutes;

[0041] Combine 11 parts of water at 85°C, 1 part of salt, 2 parts of alkali, 2 parts of soda and 4 parts of urea for batik dyeing;

[0042] fade wax;

[0043] All sealing wax;

[0044] Refer to the parts that need to make watermarks image 3 As shown in the comparison picture of the silk fabric before dyeing; the part that needs to be made of water pattern is kneaded to break the wax;

[0045] The temperature is controlled at 30°C, adjusted with 84 disinfectant and water at a ratio of 1:4, soaked for 35 minutes to achieve degumming, iron the fabric after degumming, and mount.

Embodiment 3

[0047] At a temperature of 40°C, use 84 disinfectant and clean water at a ratio of 1:4, soak for 25 minutes;

[0048]Combine 9 parts of water at 90°C, 1 part of salt, 2 parts of alkali, 2 parts of soda and 4 parts of urea for batik dyeing;

[0049] fade wax;

[0050] All sealing wax;

[0051] Refer to the parts that need to make watermarks image 3 As shown in the comparison picture of the silk fabric before dyeing; the part that needs to be watered is broken by patting the wax;

[0052] The temperature is controlled at 20°C, adjusted with 84 disinfectant and water at a ratio of 1:3, soaked for 25 minutes to achieve degumming, after degumming, iron the fabric, and mount it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com