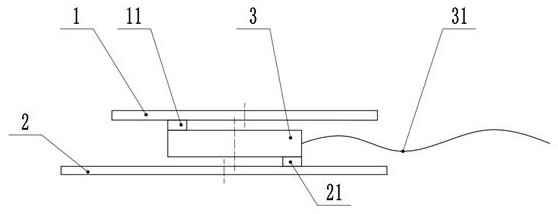

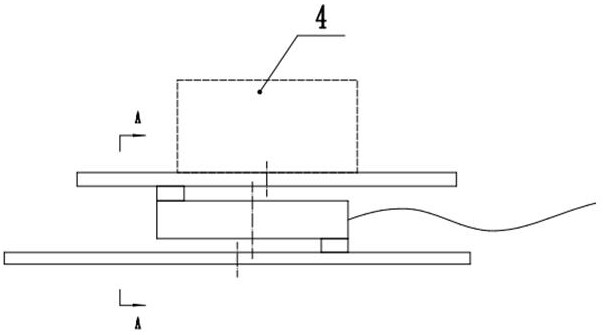

High-rigidity and low-unbalance-load weighing pallet and manufacturing method thereof

A high-rigidity, weighing technology, applied to the detailed information of weighing equipment, weighing, weighing auxiliary equipment, etc., can solve the problems of large influence, eccentric load error of weighing device, and unfavorable eccentric load error, etc. , to achieve the effect of eliminating unbalanced load, solving large measurement errors and shortening assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

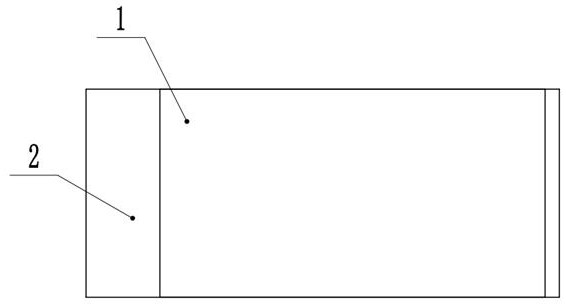

[0046] Embodiment 2. The difference between this embodiment and Embodiment 1 is that the first tray 12 and the second tray 22 are both circular.

Embodiment 3

[0047] Embodiment 3. The difference between this embodiment and Embodiment 1 is that the first tray 12 is rectangular, and the second tray 22 is circular.

[0048] Working principle: For a support platform with a rectangular plane, its center of mass is the center of the diagonal of the rectangle. At present, a large number of cantilever beam sensor weighing devices adopt the arrangement where the center of mass of the platform coincides with the center of mass of the sensor in the vertical direction. It is unreasonable, because when the center of mass coincides with the arrangement, the force on both sides of the symmetry will have different moment effects on the center of mass. For example, one side will be easier to settle than the other side, which will cause the side to easily reach the range limit under eccentric load. . Therefore, the present invention adopts a more reasonable layout, so that the centroid of the first support platform falls between the first contact par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com