Automatic detection system and method for engineering machinery fault display instrument

A fault display and automatic detection technology, applied in the testing of mechanical parts, the testing of machine/structural parts, instruments, etc., can solve the problem of large amount of text input, improve the search speed, reduce the error rate, and reduce the number of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further illustrate the technical solution details of the present invention, it will be described in connection with the accompanying drawings.

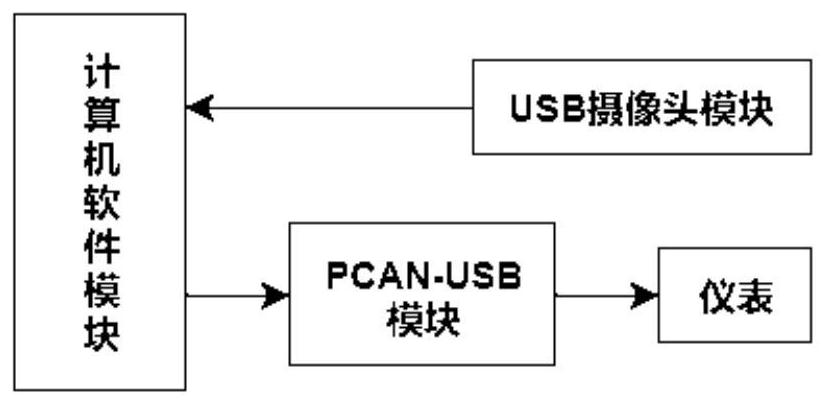

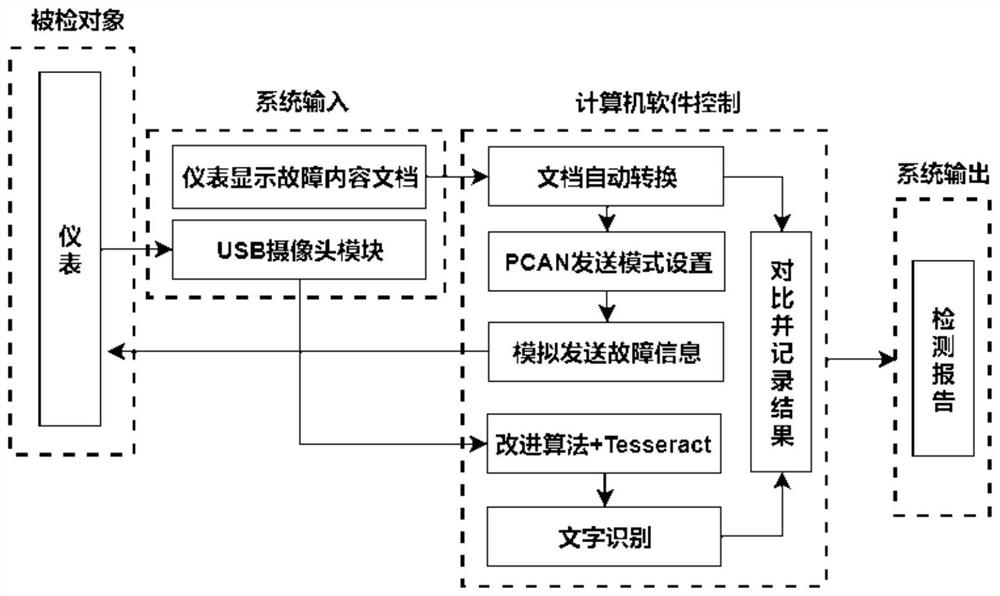

[0044] Such as figure 1 As shown, the present invention includes a fault simulation transmission module, a camera module, a computer software module, and a communication module; the computer software module communicates data communication through a communication module and a fault analog transmission module and a camera module, said fault analog transmission module passed The communication module is connected to the detected meter.

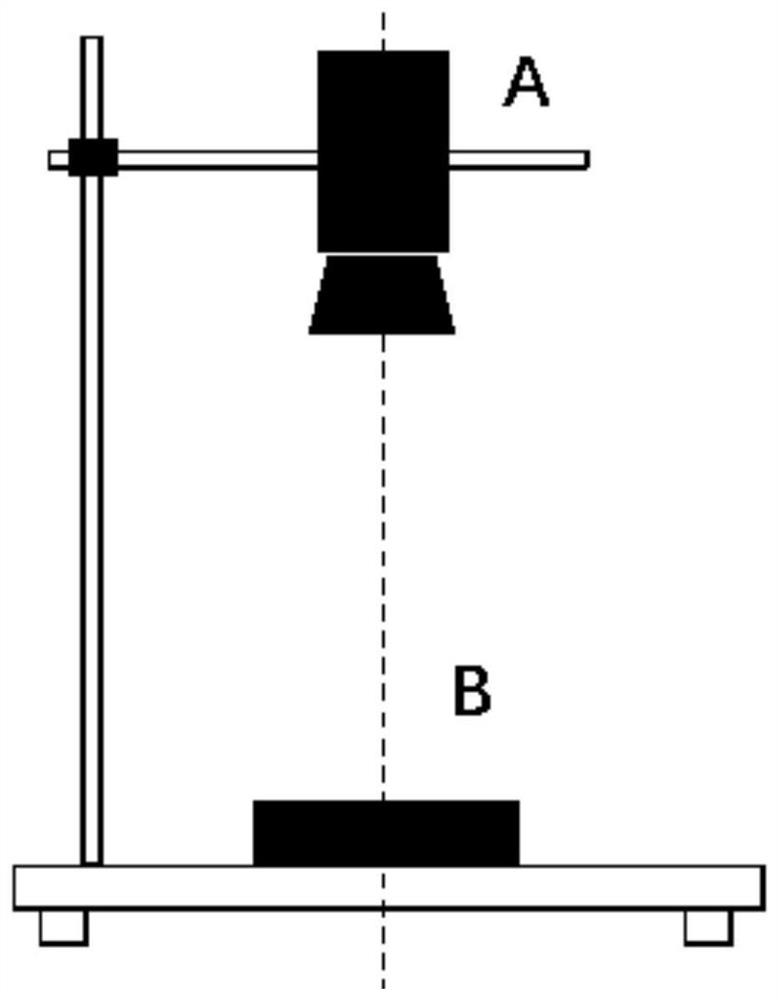

[0045] Such as figure 2 As shown, in the process of use of the present invention, in order to improve the identification of the instrument interface text, the camera mounting bracket is designed, including the detection platform 1, the side of the detection platform 1 mounted with a bracket 2, and the upper portion of the stent 2 is mounted. The camera mount 3, the camera mounting frame 3 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com