Green building engineering all-glass curtain wall construction system and construction method

A green building, glass curtain wall technology, applied in construction, building maintenance, building construction, etc., can solve the problems of declining overall aesthetics, low work efficiency, high cost, high use and promotion value, convenient maintenance, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

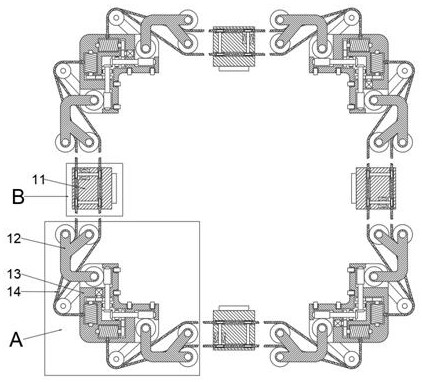

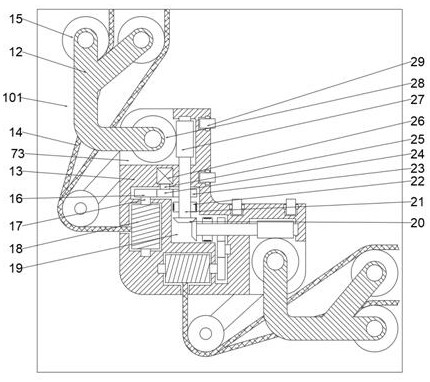

[0023] The present invention will be described in detail below in conjunction with the above-mentioned diagrams, wherein, for the convenience of description, the orientations mentioned below are stipulated as follows: figure 1 The up and down directions of the projection relationship are the same.

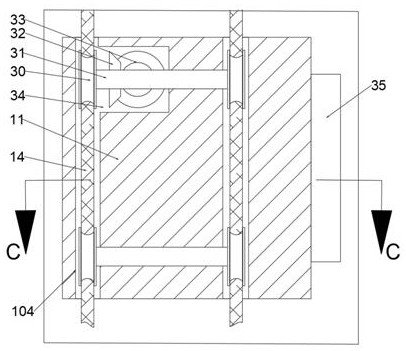

[0024] Such as Figure 1-6 As shown, a kind of green building engineering all-glass curtain wall construction system of the present invention includes four sets of supporting shells 13 evenly arranged, and the adjacent two sets of supporting shells 13 are connected by cables 14, and the cables 14 The upper slide is provided with a working shell 11, and the support shell 13 is provided with a support cavity 19, and the end wall of the support shell 13 close to the glass curtain wall is evenly provided with eight sets of rotatable rubber wheels 29, Further, to reduce the pressure of the system on the glass curtain wall, the supporting housing 13 is symmetrically provided with a pres...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap