Non-freezing liquid concentration and purification device

A liquid storage and liquid storage tank technology is applied in the field of antifreeze concentration and purification devices, which can solve the problems of increased freezing point of antifreeze concentration, high electric heating defrosting power, and large electric heating power, etc., and saves labor costs and time. cost, improve production efficiency, improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

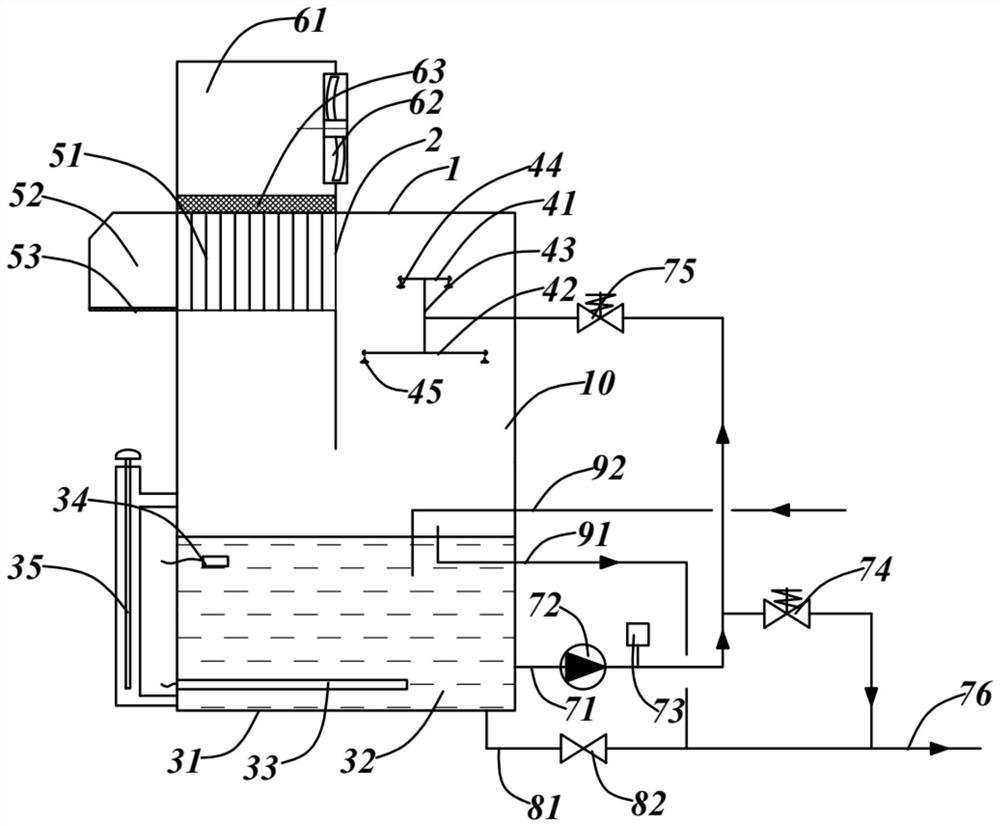

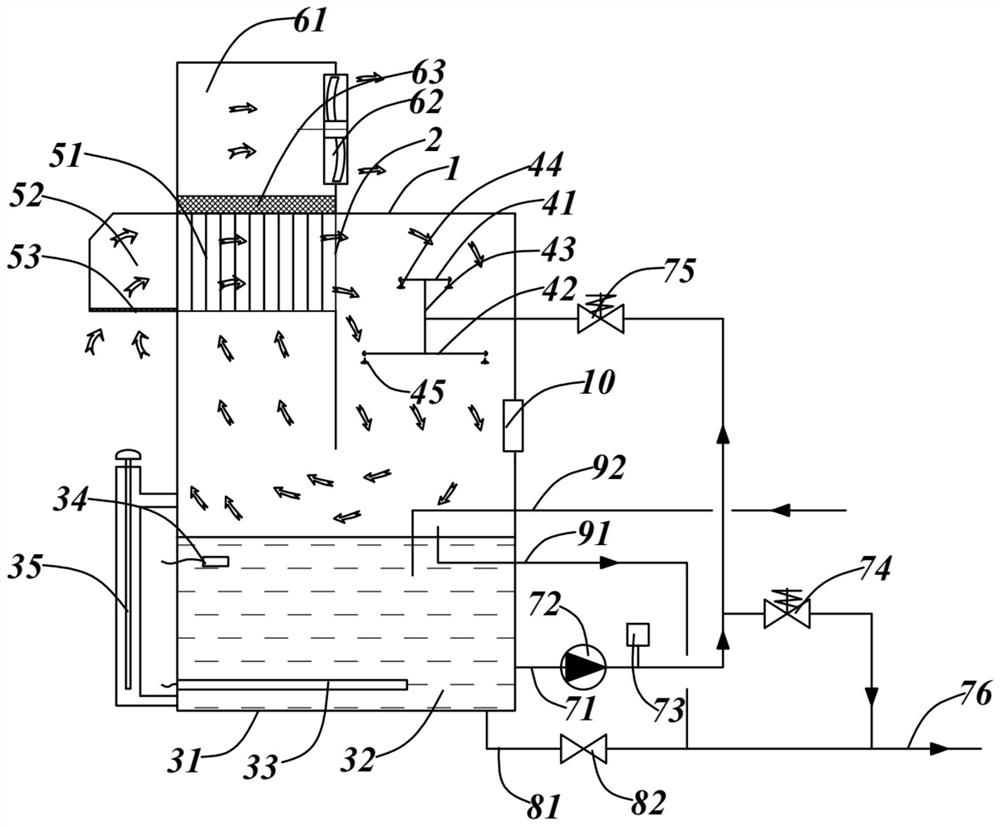

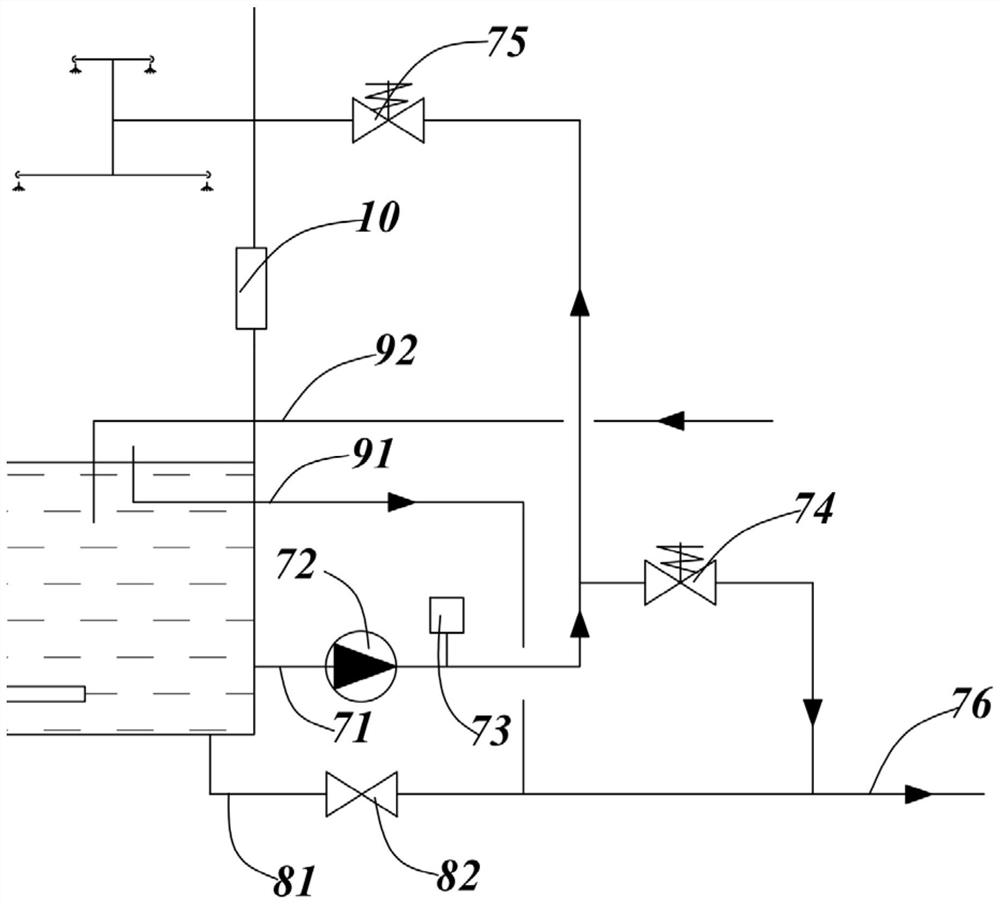

[0023] Such as figure 1 and figure 2 An antifreeze concentration and purification device is shown, which is characterized in that it includes a tank 1, a liquid storage unit arranged at the bottom of the tank 1, a spray unit and a heat exchange unit arranged above the liquid storage unit, and a spray unit arranged on the spray The baffle 2 between the unit and the heat exchange unit, the exhaust unit and the infusion unit arranged on the top of the box body 1, the spray unit and the heat exchange unit are separated by the baffle 2, and the exhaust unit is separated from the heat exchange unit The unit is connected, and the infusion unit is connected with the liquid storage unit and the spray unit. The function of the baffle 2 is to block the water vapor and antifreeze 32 droplets after spraying, preventing them from directly entering the heat exchanger 51. Due to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com