Hoisted cement pipe outer wall brushing device

A cement pipe and wall brush technology, which is used in grinding drive devices, grinders, ceramic molding machines, etc., can solve the problems of inability to move, large devices, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

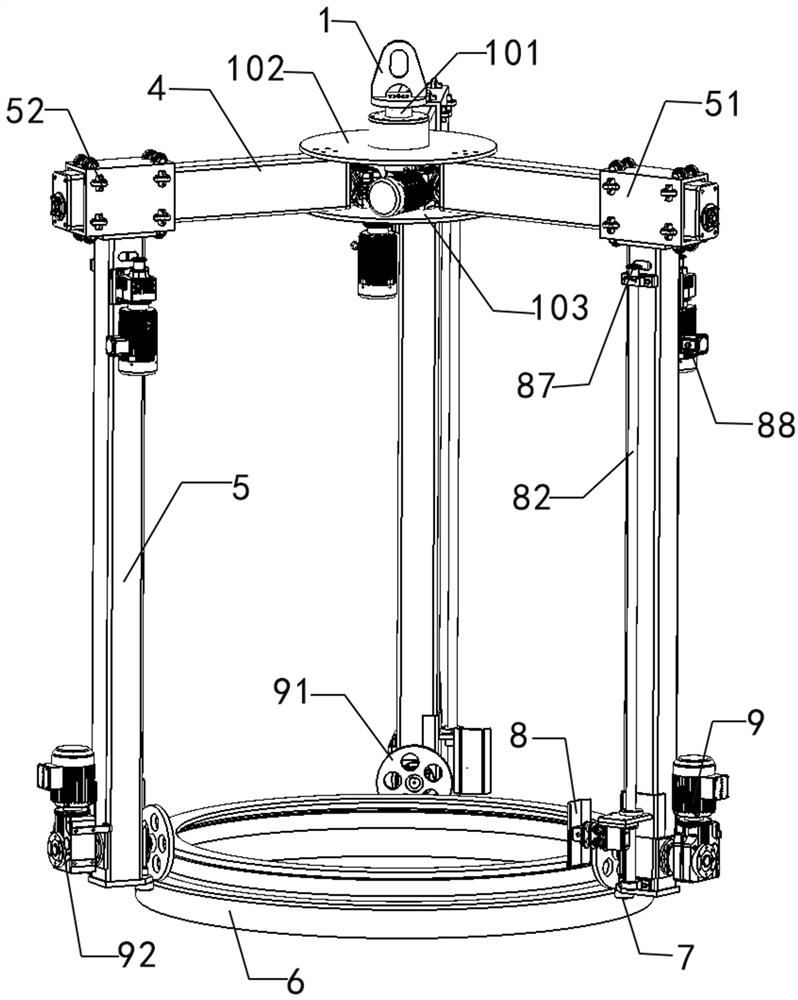

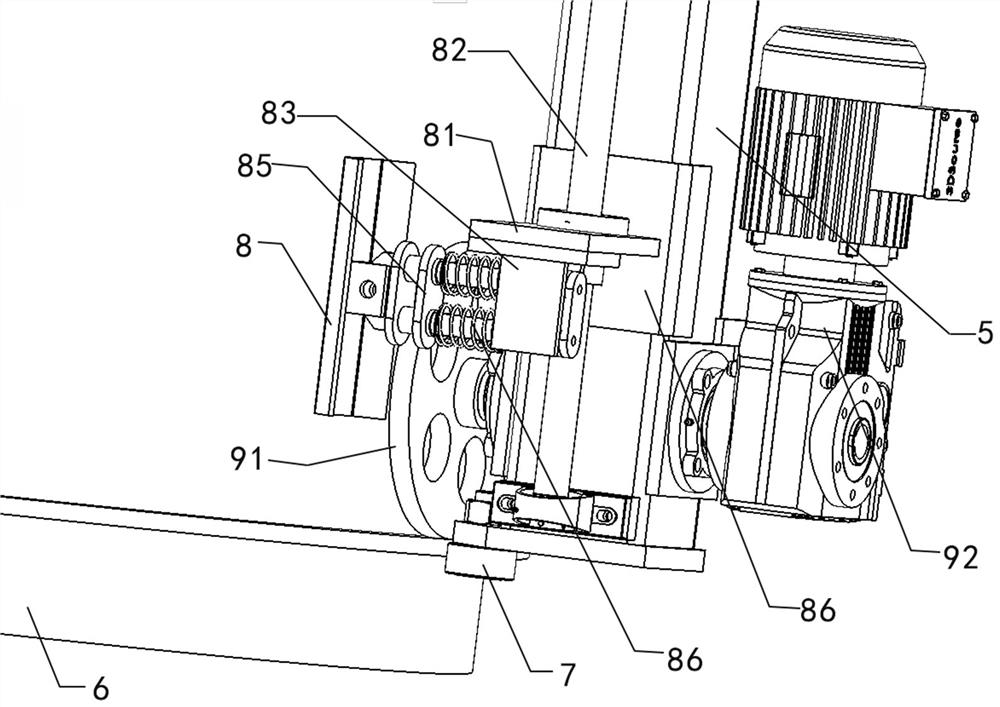

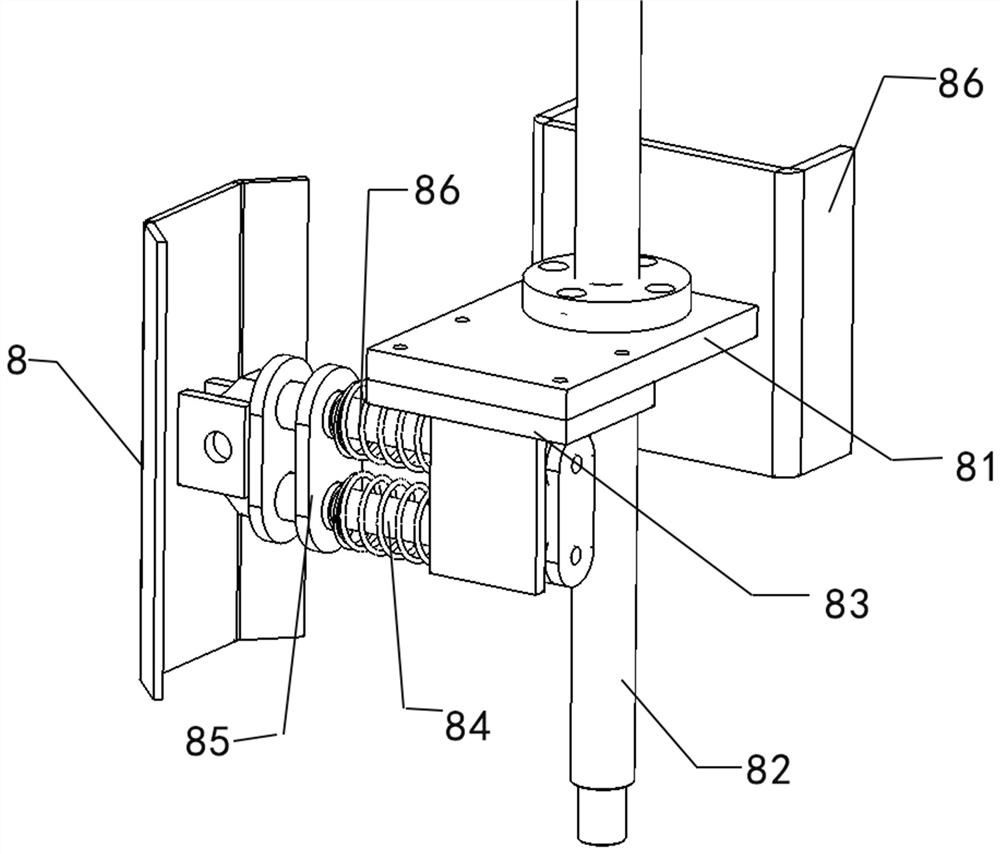

[0025] Such as Figure 1-9 As shown, a device for brushing the outer wall of a cement pipe for hoisting comprises a hoisting plate 1, a rotating shaft 101 is arranged under the hoisting plate 1, a rotating plate 102 rotating around the rotating shaft 101 is arranged on the rotating shaft 101, and at least two groups of transverse The bracket 4 and the horizontal bracket 4 are generally set according to the diameter of the pipe, usually three groups, four groups, five groups or six groups. In this embodiment, the horizontal brackets 4 are three groups, which are regularly arranged on the rotating plate 102. In order to increase the horizontal bracket 4 stability, in this embodiment, a bearing plate 103 is provided under the transverse support 4, and the bearing plate 103 is fixedly connected to the transverse support 4 and the rotating plate 102 through fixing parts (such as bolts).

[0026] In this embodiment, the cross-section of the transverse support 4 is rectangular. The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com