Foaming equipment achieving good foaming effect for production of polyurethane foam plastic

A foamed plastic and foaming equipment technology, which is applied in the field of foaming equipment with good foaming effect for the production of polyurethane foamed plastics, can solve the problems of poor quality control of polyurethane foamed plastics, inconvenient dosage of foaming raw materials, and polyurethane foamed plastics. The quality does not meet the standard and other problems, to achieve the effect of a wide range of applications, good foaming effect and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

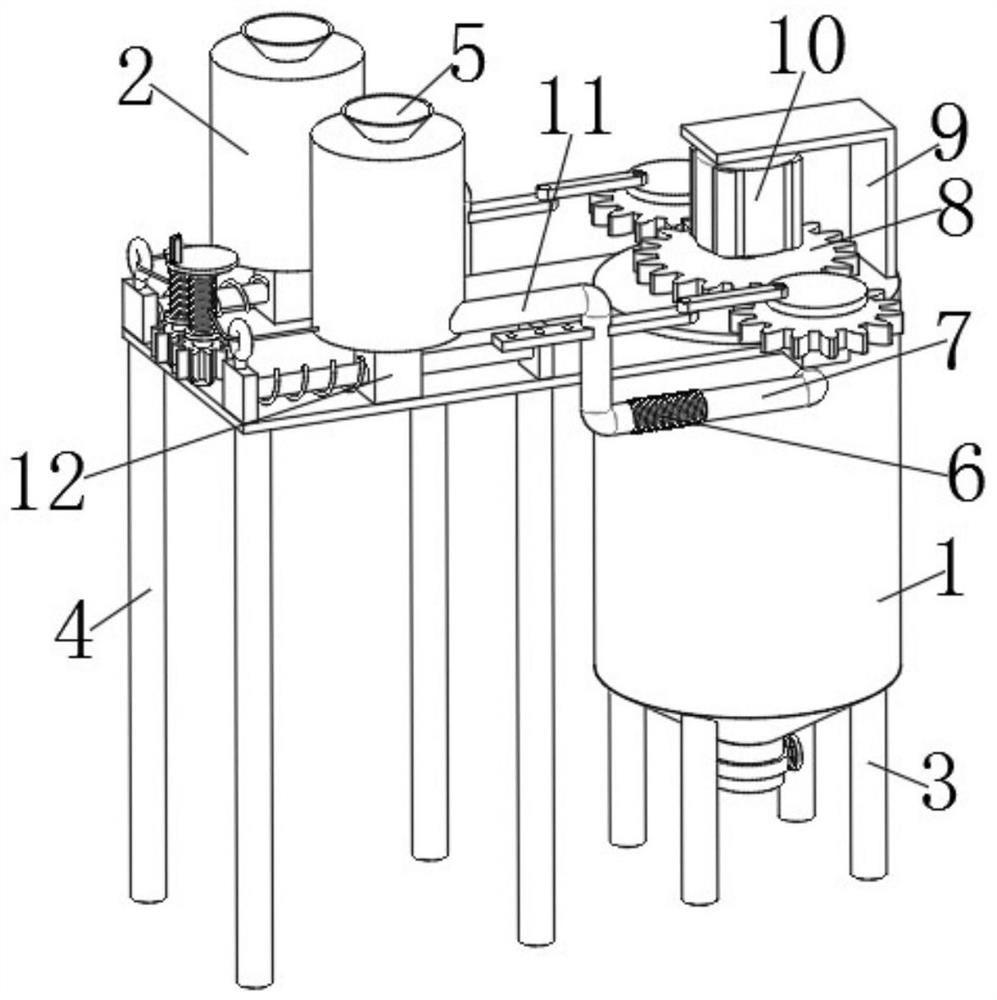

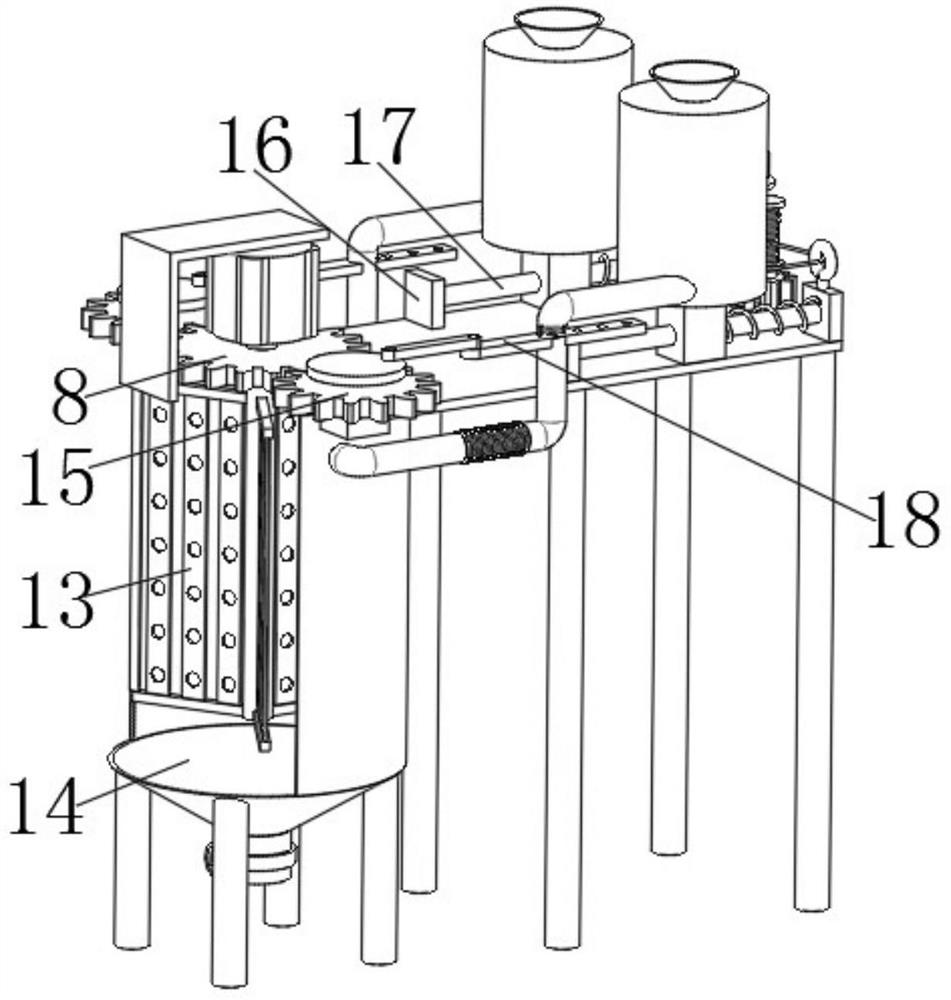

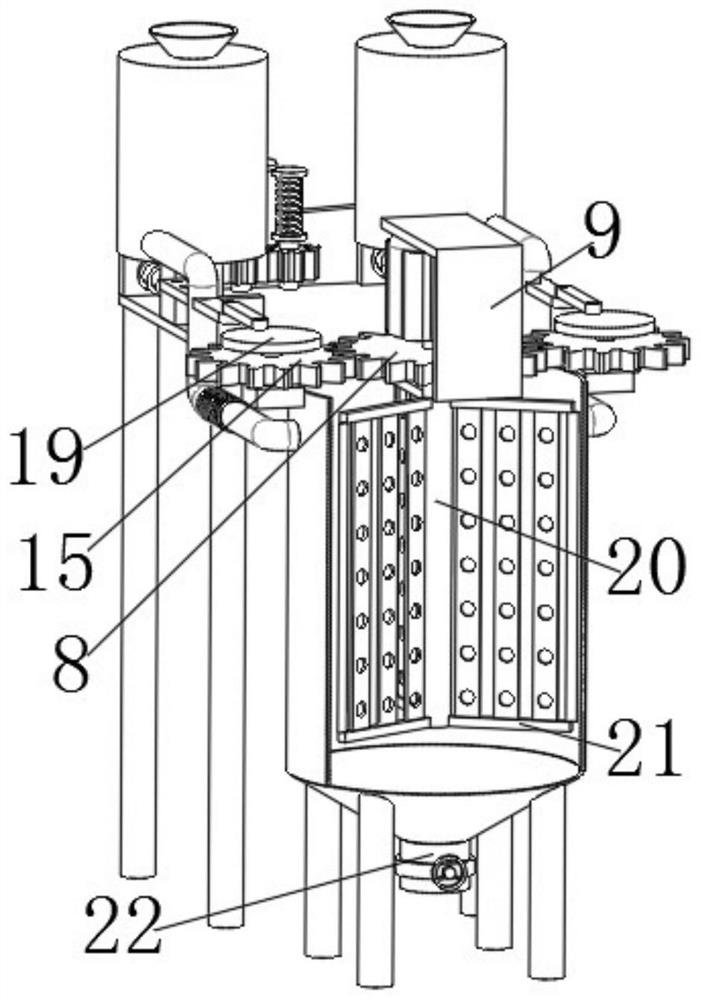

[0042] Example: Reference Figure 1-8 A kind of foaming equipment with good foaming effect shown in the production of polyurethane foam comprises a foaming box 1, two raw material boxes 2 arranged above the foaming box 1, and the side walls of the two raw material boxes 2 are all fixed A conduit 11 is installed, and the conduit 11 can be any metal pipe in the prior art, which is welded with the side wall of the raw material box 2 for fixing.

[0043] One end of the two conduits 11 is fixedly equipped with a flexible hose 6, and one end of the two flexible hoses 6 is fixedly equipped with a connecting pipe 7, and the connecting pipe 7 can be any metal pipe in the prior art. One end of flexible pipe 6 is welded and fixed.

[0044] One end of the two connecting pipes 7 is all fixedly installed on the side wall of the foaming box 1, and the side wall of the foaming box 1 is fixedly equipped with a mounting plate and two fixing blocks 30, and the mounting plate can be any one of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com