Drying, pressing, leveling and dehumidifying treatment device for paper products

A paper product and wet treatment technology, applied in the field of paper product processing, can solve the problems affecting the overall quality of the product, the retention of dust and impurities, etc., and achieve the effects of improving the scope of application, preventing secondary pollution, and improving the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

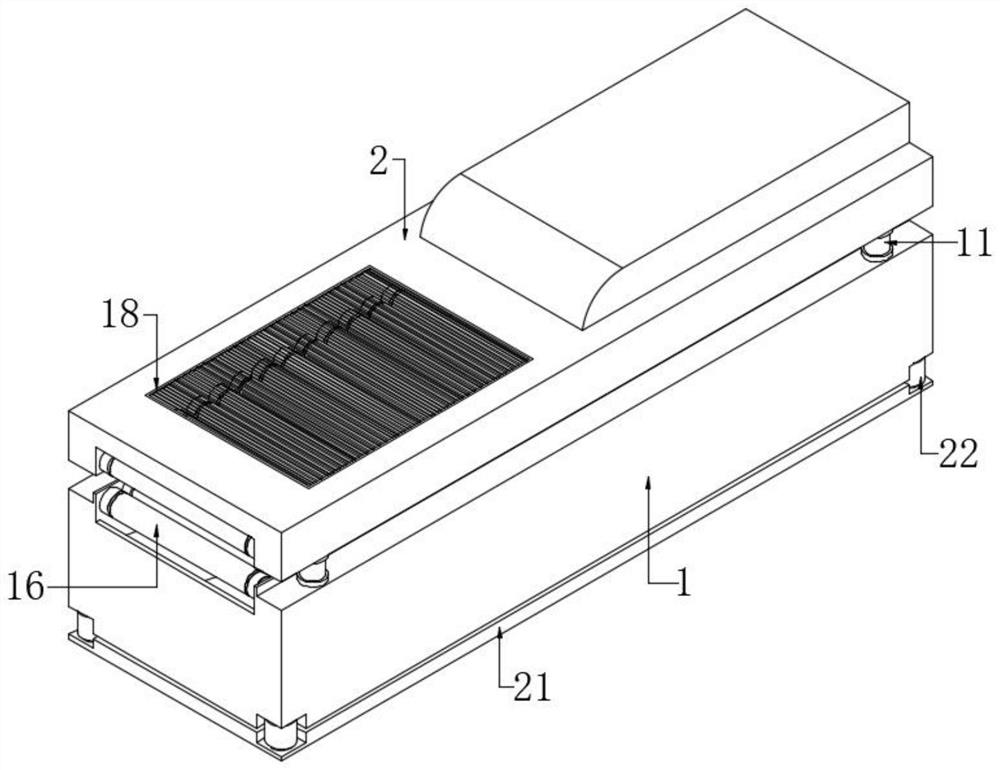

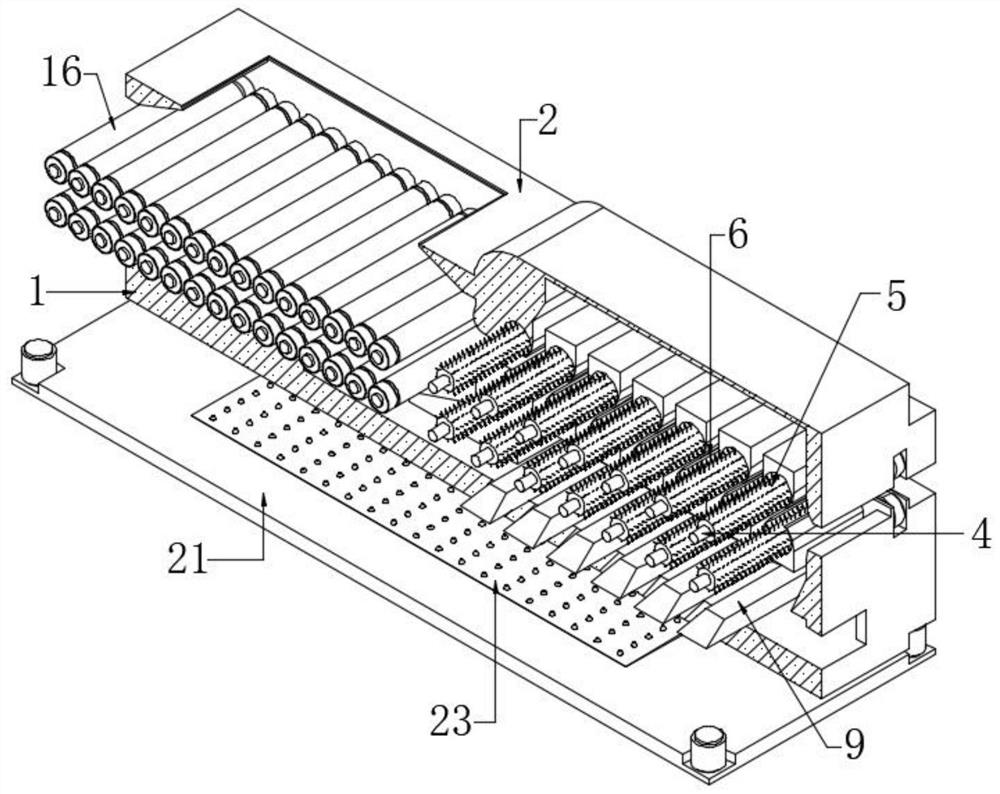

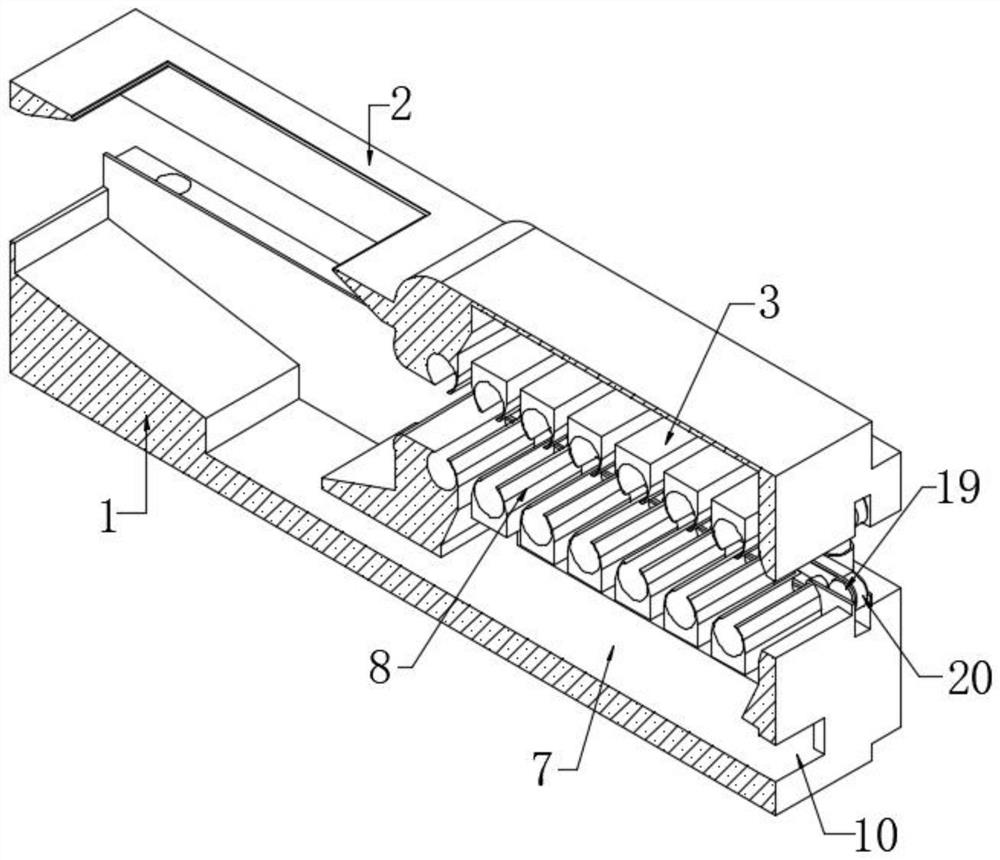

[0026] refer to Figure 1-4 , a paper product baking, leveling and dehumidification treatment device, including a base 1 and a cover box 2, the interior of the base 1 and the cover box 2 are both set as cavities, and the inner walls on both sides of the base 1 and the cover box 2 are passed through Bolts are connected with a plurality of brush holders 3, and the inner walls on both sides of the plurality of brush holders 3 are connected with a rotating rod 4 through bearing rotation, and the outer wall of the rotating rod 4 is connected with a cleaning cylinder 5 by bolts, and the outer wall of the cleaning cylinder 5 is set A plurality of soft brushes 6 are arranged, and a dust collection box 7 is arranged inside the base 1 , and one side of the dust collection box 7 is provided with an air suction port 10 , and the other end of the air suction port 10 runs through one side of the outer wall of the base 1 .

[0027] In the present invention, an externally expanded dust suctio...

Embodiment 2

[0035] refer to Figure 5 , a paper product baking, leveling and dehumidification treatment device. Compared with Embodiment 1, this embodiment also includes a chute at the bottom of the dust collection box 7, and a cleaning seat 24 is slidably connected to the inner wall of the chute. The cleaning seat 24 The outer wall of the lower side of the lower side is connected with a plurality of cleaning brushes 25 by bolts, and a threaded hole is provided on the cleaning seat 24, and the inner wall of the threaded hole is rotatably connected with a lead screw 26. The inner walls on both sides are rotationally connected by bearings

[0036] During use, in the process of use, there will be some accumulation of dust and impurities in the dust collection box 7, and the screw 26 drives the cleaning seat 24 to perform lateral reciprocating motion to brush the inner wall of the dust collection box 7 to assist the detachment of dust and impurities , Avoid too much impurities inside the vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com