Carrying carton with bottom self-weight locking and sealing structure

A carton and sealing technology, used in locking equipment, external accessories, container handles, etc., can solve the problems of unfavorable handling of carton recycling, low fastening and tightening, and increased investment costs, so as to improve the reuse rate and reduce The effect of input cost and reduction of floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

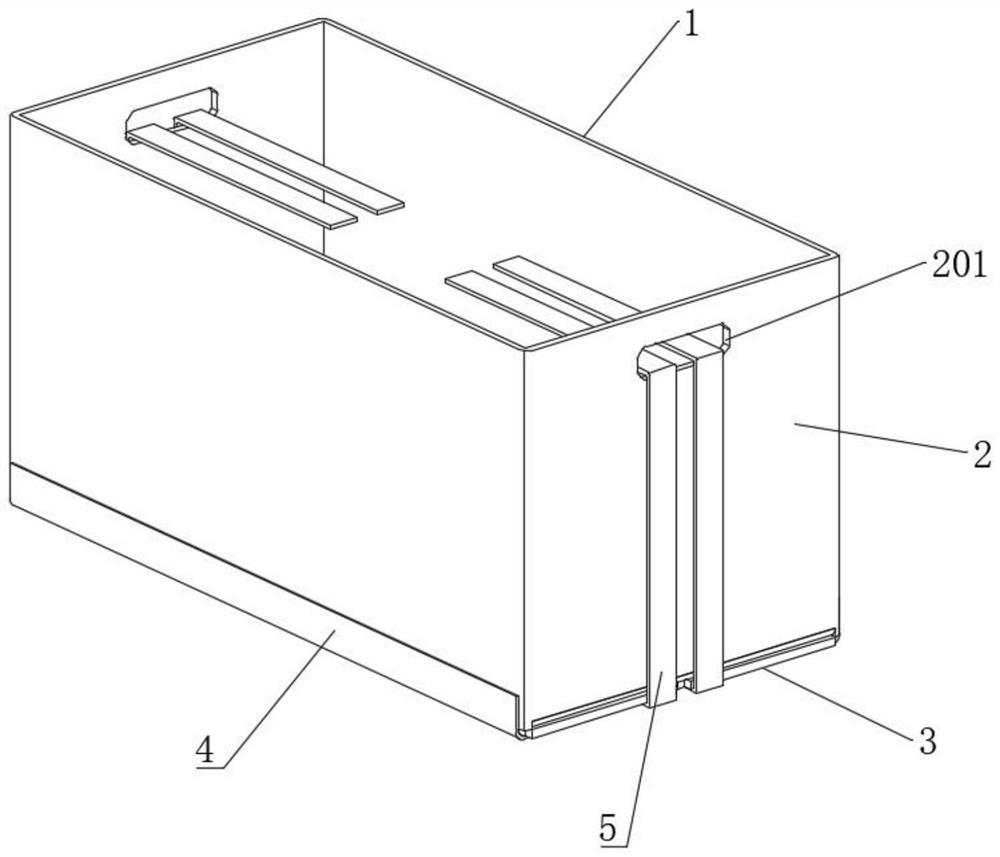

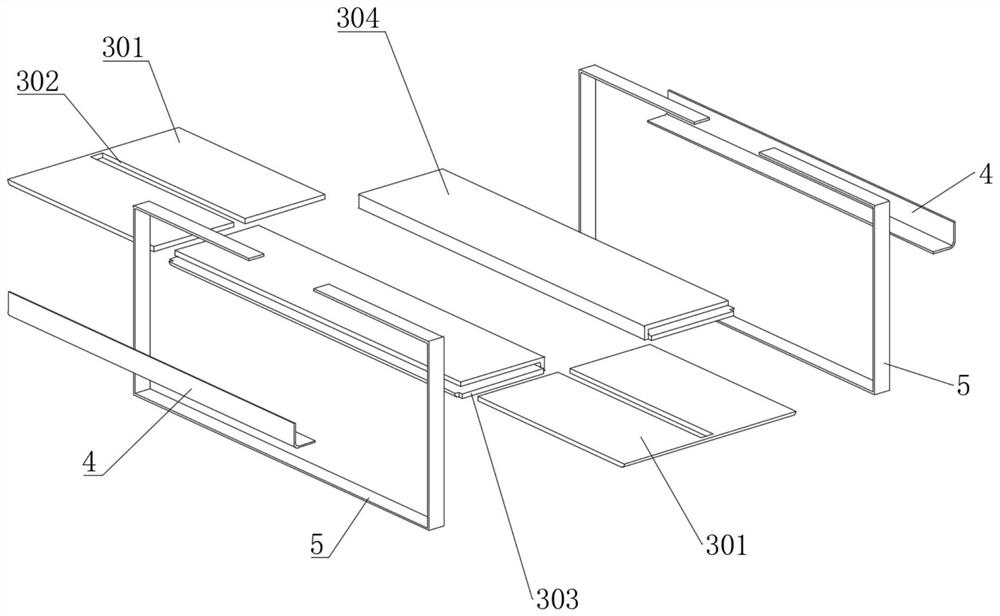

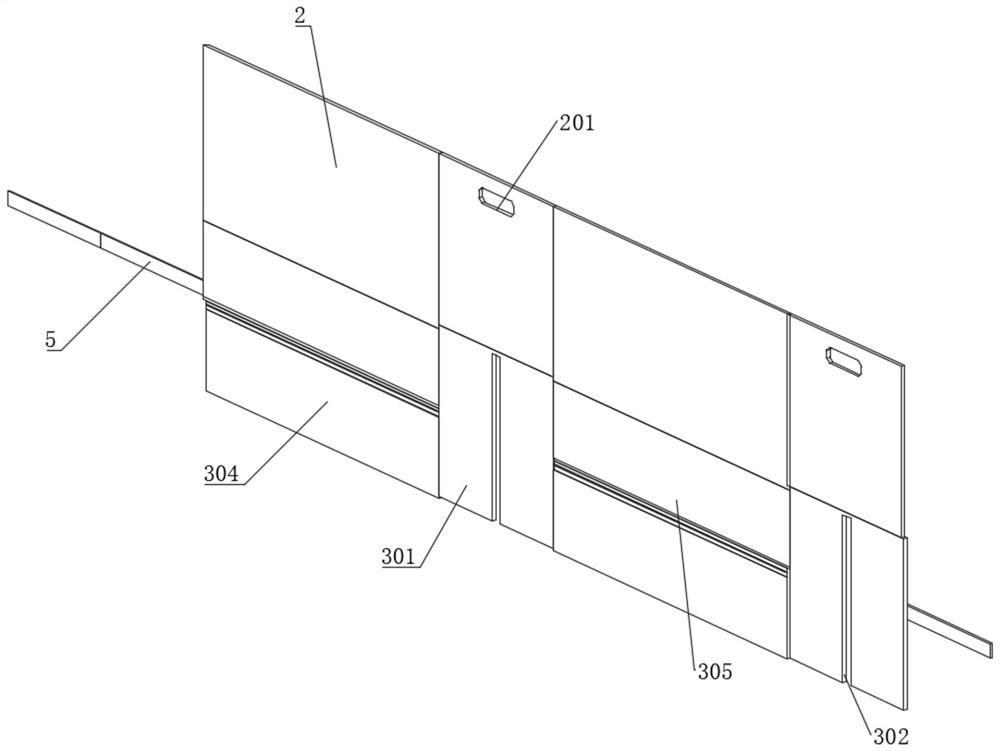

[0059] see Figure 1-12 , a carrying carton with a self-weight locking and sealing structure at the bottom, including a carton body 1, the carton body 1 includes a box body 2, a gravity self-locking floor assembly 3 is connected to the lower end of the box body 2, and the gravity self-locking floor assembly 3 includes a narrow The side bottom plate 301, the narrow side bottom plate 301 is fixedly connected to the front and rear ends of the box body 2, the wide side bottom plate 303 located at the lower side of the narrow side bottom plate 301 is fixedly connected to the left and right ends of the box body 2, and the two wide side bottom plates 303 are close to each other One end is fixedly connected with a gravity self-locking plate 304 , and a self-locking plate hole 302 matching the gravity self-locking plate 304 is opened on the narrow side bottom plate 301 . Through the mutual cooperation of the narrow side bottom plate 301, the wide side bottom plate 303 and the gravity s...

Embodiment 2

[0069] see Figure 1-12 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to Figure 11 , the processing technology of carton body 1 is the following steps:

[0070] M1. Preliminary bonding: use the No. 1 dispensing equipment to bond the honeycomb reinforcement board 102 on both ends of the corrugated buffer board 103, and dry and fix it;

[0071] M2. Re-bonding: Use No. 2 glue dispensing equipment to bond the plastic moisture-proof board 101 on the outer end surface of the honeycomb reinforced board 102, and perform pressing, drying and fixing;

[0072] M3. Board making: according to the size of the customized carton body 1, use cutting equipment to cut out the composite board for making the carton body 1;

[0073] M4. Detail...

Embodiment 3

[0076] see Figure 1-12 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 3 and embodiment 1 is: please refer to Figure 7-10 with Figure 12 , the method of using the gravity self-locking floor assembly 3 is as follows:

[0077] S1. Fold the two narrow bottom plates 301 toward the box body 2 to cover the lower end of the box body 2;

[0078] S2. Then insert the gravity self-locking plate 304 into the hole 302 of the self-locking plate, and drive the wide-side bottom plate 303 to fold toward the box body 2 until the gravity self-locking plate 304 completely enters the box body 2;

[0079] S3. Use your hands to press the wide-side bottom plate 303, so that the wide-side bottom plate 303, the narrow-side bottom plate 301 and the box body 2 are fastened;

[0080] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com