A kind of production method of polycarboxylate high-performance water reducing agent for concrete pipe pile

A technology for a concrete pipe pile and a production method, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as poor slump retention, improve stability, improve compressive strength retention of pipe piles, eliminate The effect of steam curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

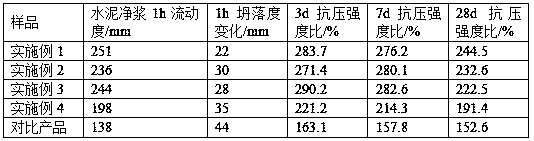

Examples

Embodiment 1

[0014] A production method of a novel polycarboxylate high-performance water reducer for concrete pipe piles, the production method of the water reducer comprises the following steps:

[0015] a. Heat clear water to 65°C, dissolve monomethoxypolyethylene glycol methacrylate, chitosan, and ammonium persulfate in water respectively, and the monomethoxypolyethylene glycol methacrylate and shell The weight ratio of polysaccharides is 1:1~2:1, the molar weight of ammonium persulfate accounts for 5% of the total molar weight of all monomers, and is added dropwise at a constant speed at the same time, and the dropwise addition is completed within 1.5 hours;

[0016] b. React at constant temperature for 3 hours, cool to room temperature after the reaction, and neutralize to weak alkalinity with 1 mol / L sodium hydroxide solution;

[0017] c. Distill the solution under reduced pressure to remove most of the water, and use solvent extraction to obtain the product, or directly remove all ...

Embodiment 2

[0019] A production method of a novel polycarboxylate high-performance water reducer for concrete pipe piles The production method of the water reducer includes the following steps:

[0020] a. Heat clear water to 80°C, dissolve monomethoxypolyethylene glycol methacrylate, sodium carboxymethylcellulose, acrylic acid, and ammonium persulfate in water respectively, and the monomethoxypolyethylene glycol methyl Acrylic acid ester, carboxymethyl cellulose sodium and acrylic acid weight ratio are 10:1:20, and the molar weight of ammonium persulfate accounts for 3% of the total molar weight of all monomers, and is added dropwise at a constant speed at the same time, and the dropwise addition is completed within 1 hour. ;

[0021] b. React at constant temperature for 3 hours, cool to room temperature after the reaction, and neutralize to weak alkalinity with 1 mol / L sodium hydroxide solution;

[0022] c. Distill the solution under reduced pressure to remove most of the water, and us...

Embodiment 3

[0024] A production method of a novel polycarboxylate high-performance water reducer for concrete pipe piles, the production method of the water reducer comprises the following steps:

[0025] a. Heat clear water to 90°C, dissolve monomethoxypolyethylene glycol methacrylate, acrylic acid, β-cyclodextrin, and ammonium persulfate in water respectively, and the monomethoxypolyethylene glycol methyl The weight ratio of acrylate, acrylic acid and β-cyclodextrin is 10:1:10, the molar weight of ammonium persulfate accounts for 3% of the total molar weight of all monomers, and is added dropwise at a constant speed at the same time, and the dropwise addition is completed within 1 hour;

[0026] b. React at constant temperature for 3 hours, cool to room temperature after the reaction, and neutralize to weak alkalinity with 1 mol / L sodium hydroxide solution;

[0027] c. Distill the solution under reduced pressure to remove most of the water, and use solvent extraction to obtain the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com