Stacker-reclaimer coal drop pipe shunting door angle adjusting buffer device

A technology of angle adjustment and buffer device, which is applied in the direction of conveyor control device, conveyor, loading/unloading, etc., can solve problems such as imbalance, overload shutdown of downstream belt conveyor, etc., to improve accuracy rate, avoid overload shutdown, and adapt to the environment strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

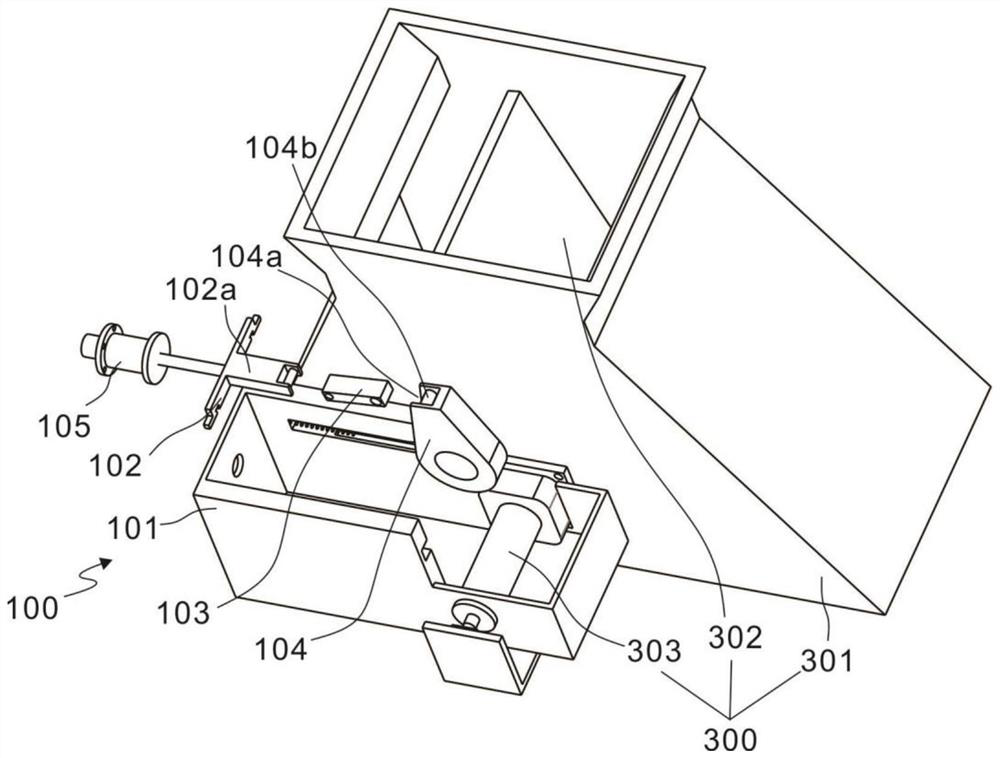

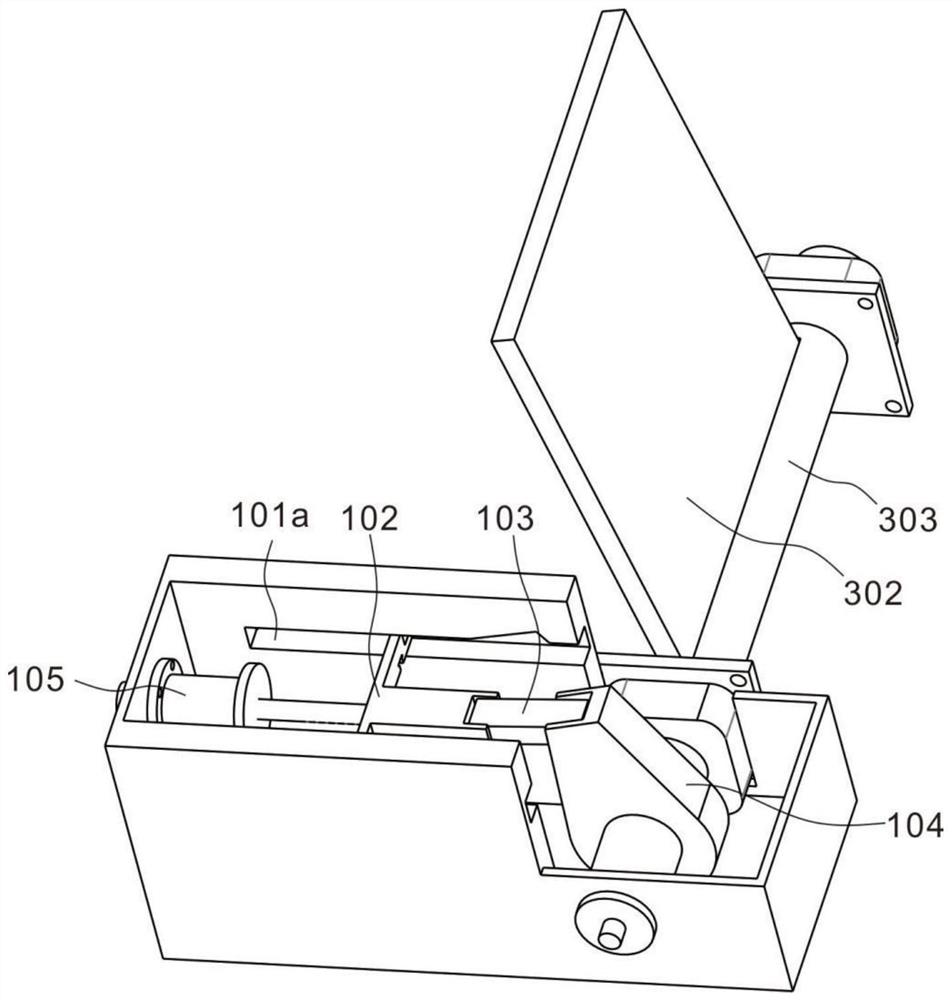

[0036] refer to Figure 1~3 , which is the first embodiment of the present invention, this embodiment provides a stacker-reclaimer coal drop pipe diverter door angle adjustment buffer device, which includes an angle adjustment assembly 100 and a coal drop assembly 300, the angle adjustment assembly 100 is arranged at the drop The outer wall of the coal assembly 300 is used to control the mixing ratio of the two coals in the coal drop assembly 300 .

[0037] The coal drop assembly 300 includes a coal drop pipe 301, a shunt door 302 and a rotating shaft 303. The coal drop pipe 301 is an existing device, and the shunt door 302 is a square plate structure, which is arranged inside the coal drop pipe 301, and the rotation shaft 303 passes through the The coal drop pipe 301 is erected on the outer walls of both sides of the coal drop pipe 301, and then one end of the diverter door 302 is fixed on the rotating shaft 303. The rotation of the rotating shaft 303 can drive the diverter d...

Embodiment 2

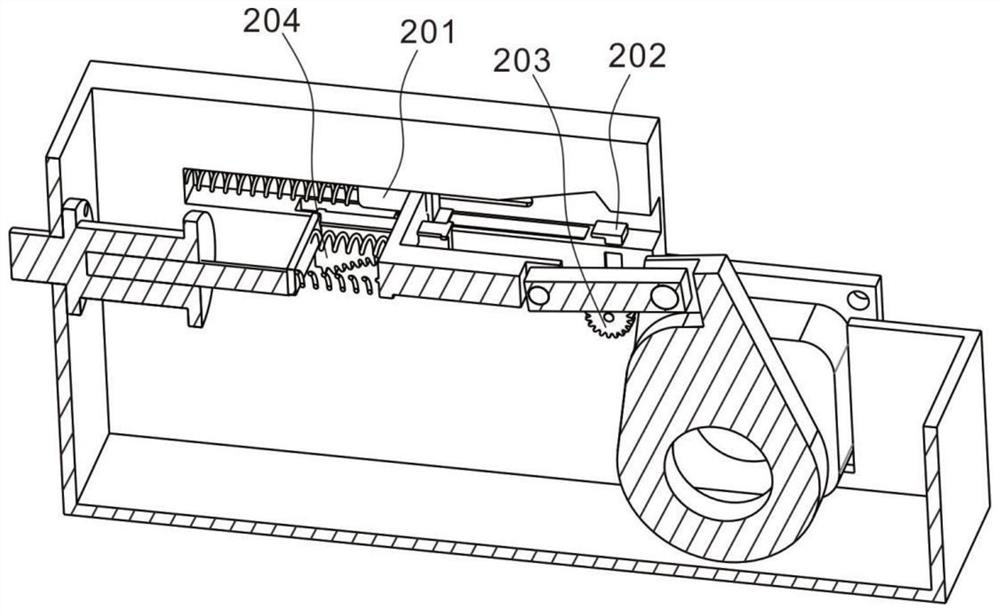

[0044] refer to Figure 4-10 , is the second embodiment of the present invention, this embodiment is based on the previous embodiment, and further includes a buffer assembly 200 , the buffer assembly 200 is arranged on both sides inside the installation shell 101 and is movably connected with the angle adjustment assembly 100 .

[0045] The buffer assembly 200 includes a lifting member 201, a floating block 202 and a gear 203. Specifically, the lifting member 201 includes a first elastic member 201a and a block 201b. The bottom is provided with a second elastic member 201b-2, and the other end of the second elastic member 201b-2 is fixedly provided with an insert 201b-3. The second elastic member 201b-2 is in a compressed state under normal conditions, and the insert 201b-3 is embedded in the first In the second chute 101b, it can be used to stabilize the movement of the block 201b. The first elastic member 201a is arranged on the first chute 101a. One end of the first elastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com