Thermal insulation coating applied to building wall

A technology for thermal insulation coatings and building walls, applied to coatings and other directions, can solve problems such as the inconspicuous thermal insulation effect of thermal insulation coatings, and achieve the effects of slowing down heat dissipation, simple construction methods, and reliable thermal insulation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

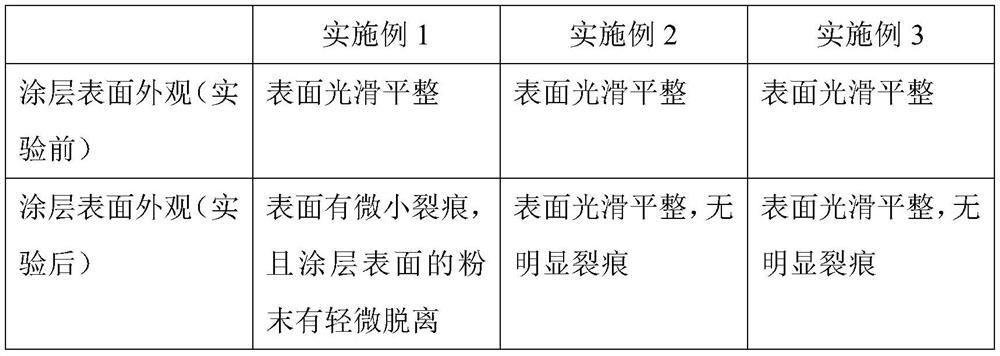

Embodiment 1

[0020] The thermal insulation coating applied to building walls in this embodiment includes the following raw materials in parts by weight: 43 parts of acrylic base polymer, 22 parts of crosslinked polymer microspheres, 35 parts of filler, and 3 parts of auxiliary agent;

[0021] Wherein the cross-linked polymer microspheres are methyl methacrylate copolymer microspheres, and the functional filler is 600 mesh floating beads;

[0022] The auxiliary agent includes surfactant, biocide, dispersant, defoamer, film-forming auxiliary agent, and the weight ratio is 1:1:1:1:1

Embodiment 2

[0024] The thermal insulation coating applied to building walls in this embodiment includes the following raw materials in parts by weight: 45 parts of acrylic base polymer, 20 parts of crosslinked polymer microspheres, 30 parts of filler, and 4 parts of auxiliary agent;

[0025] Wherein the cross-linked polymer microspheres are porous cross-linked styrene microspheres, and the functional filler is diatomite;

[0026] The auxiliary agent includes surfactant, biocide, dispersant, defoamer, film-forming auxiliary agent, and the weight ratio is 1:1:1:1:1

Embodiment 3

[0028] The thermal insulation coating applied to building walls in this embodiment includes the following raw materials in parts by weight: 40 parts of acrylic base polymer, 25 parts of crosslinked polymer microspheres, 40 parts of filler, and 2 parts of auxiliary agent;

[0029] Wherein the cross-linked polymer microspheres are porous cross-linked polymethyl methacrylate microspheres, and the functional fillers are hollow glass microspheres;

[0030] The auxiliary agent includes surfactant, biocide, dispersant, defoamer, film-forming aid, thickener, and the weight ratio is 1:1:1:1:1:1.

[0031] Coating composition density≤450kg / m among the embodiment 1-3.

[0032] Embodiment 1-2 biocide is isothiazolinone derivatives, biocide is benzimidazole esters in embodiment 3; Dispersant is polycarboxylate sodium salt class dispersant in embodiment 1-3; The foaming agent is polyether silicone oil; the film-forming aid is an alcohol ester film-forming aid; the thickener in Example 3 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com