Road roller facing system

A road roller and welting technology, which is applied in the field of road rollers, can solve the problems of extremely high requirements for the driver's operation level, high construction difficulty, and insufficient driving level, so as to improve safety and road edge construction quality, reduce operating skill requirements, Avoid the effect of inaccurate ranging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

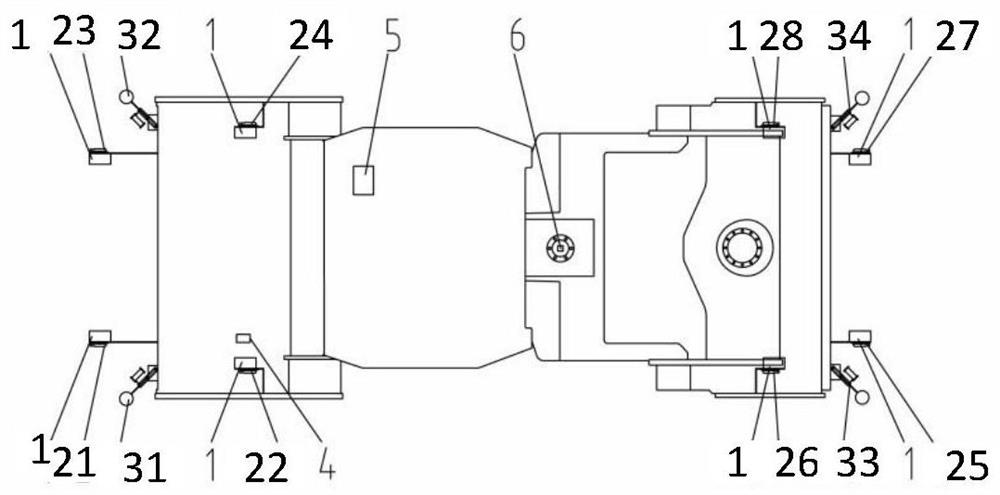

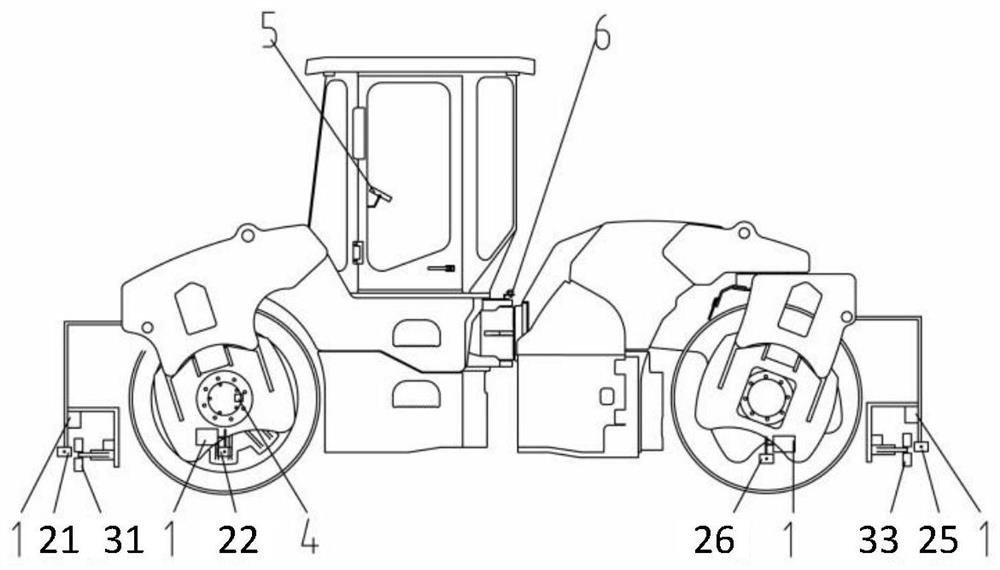

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

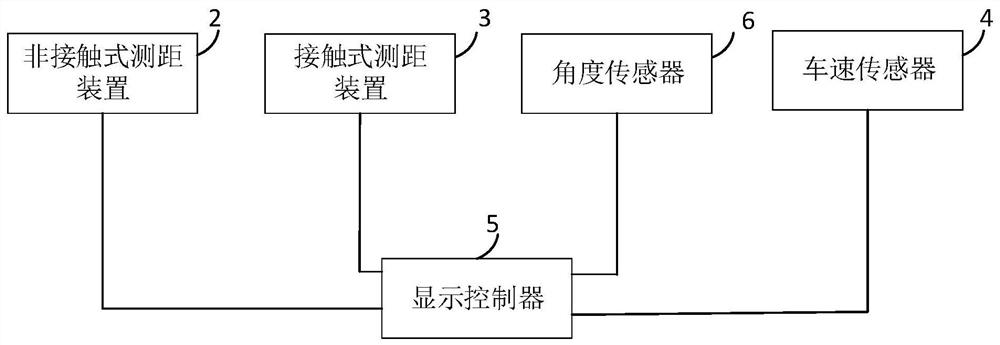

[0039] This embodiment provides a roller welting system, figure 1 It is a module schematic diagram of a road roller welting system provided by an embodiment of the present invention, refer to figure 1 , the roller welting system includes: a non-contact distance measuring device 2, a contact distance measuring device 3, an angle sensor 6, a vehicle speed sensor 4 and a display controller 5;

[0040] The non-contact ranging device 2 is used to collect the first distance between the front wheel edge of the road roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com