Vertical type revetment construction method

A construction method and vertical technology, applied in soil protection, coastline protection, infrastructure engineering, etc., can solve problems such as cracks, embankment collapse, stone falling, etc., to avoid cracks, ensure integrity, improve Effects on Carrying Capacity and Safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

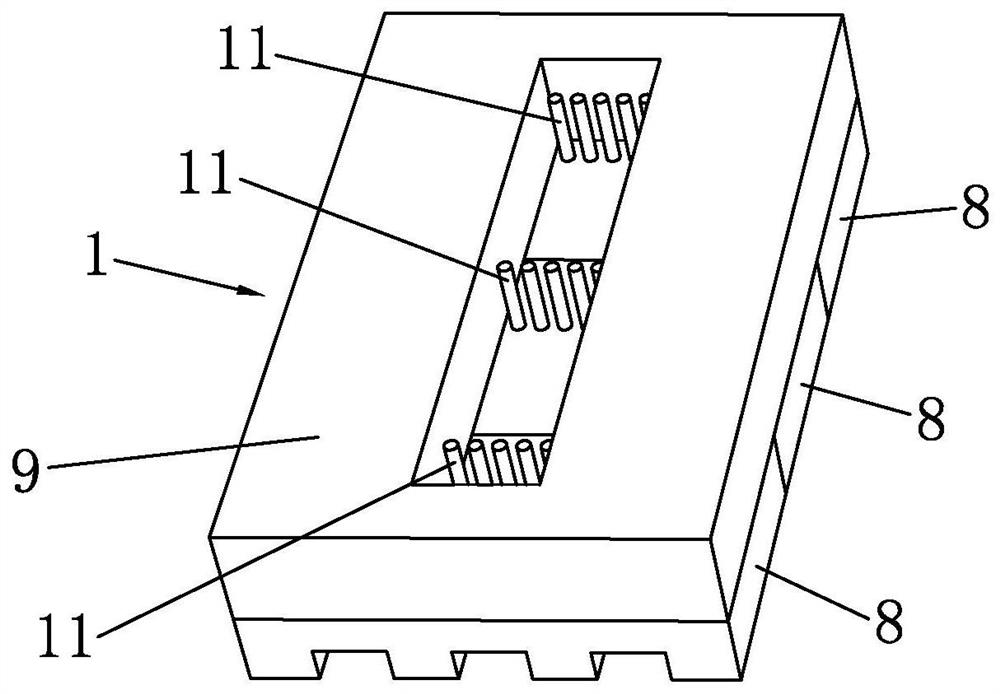

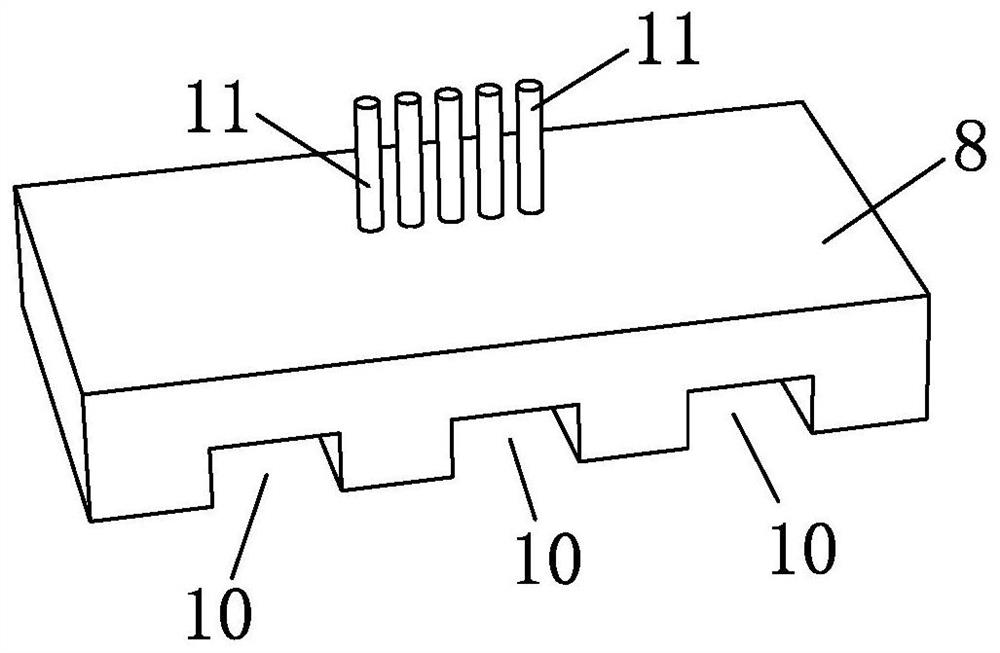

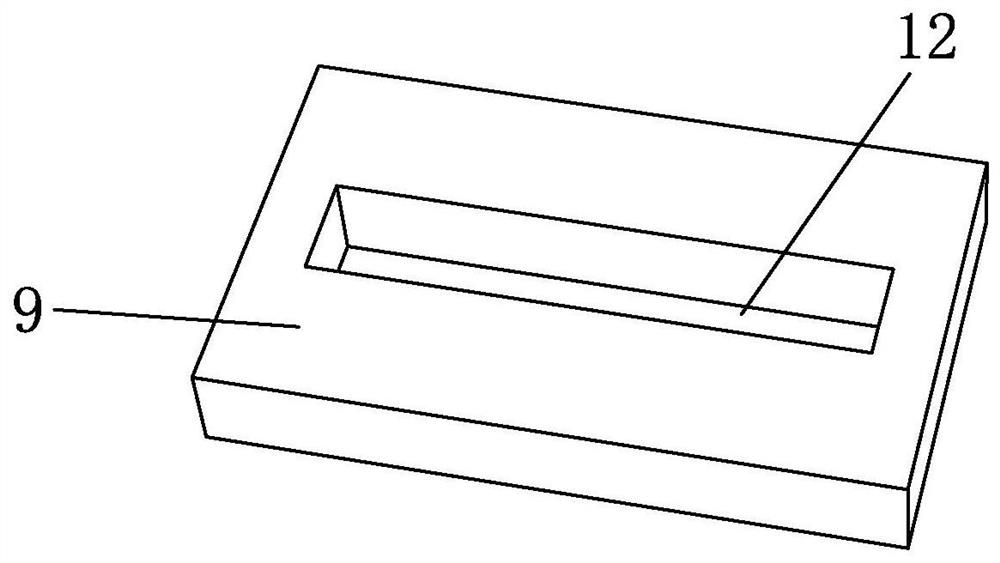

[0049] Such as Figure 1 to Figure 13 As shown, it is Embodiment 1 of the present invention,

[0050] The vertical revetment construction method is characterized in that it comprises the following steps:

[0051] a. Perform compaction and leveling operations on the foundation on the construction site. The foundation is rolled by a road roller, and the backfill soil is leveled at the same time. The degree of compaction must meet the specifications.

[0052] b. Lay multiple bottom support structures 1 on the foundation, and control the distance between two adjacent bottom support structures 1 .

[0053] The bottom support structure 1 adopts the third brick 8 and the spacer 9, the third brick 8 is integrally formed by a mold, the third brick 8 is provided with a vertical steel bar 11, and the bottom of the third brick 8 is provided with a gap 10 , the third brick 8 is laid on the foundation, the contact area between the third brick 8 and the foundation is reduced as much as pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com