Construction method of large-section variable-diameter ore storage bin formwork support

A construction method and large-section technology, applied to the accessories of scaffolding, building structure support, building structure support, etc., can solve the problems of low safety and reliability, low construction efficiency, and difficult construction, so as to improve convenience and facilitate construction , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

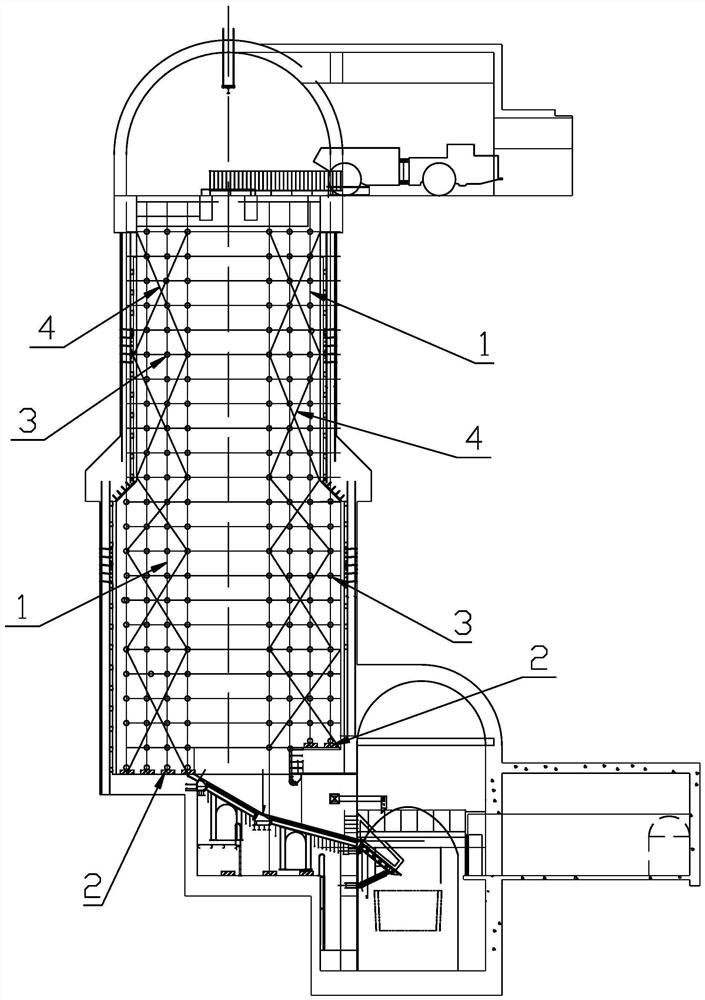

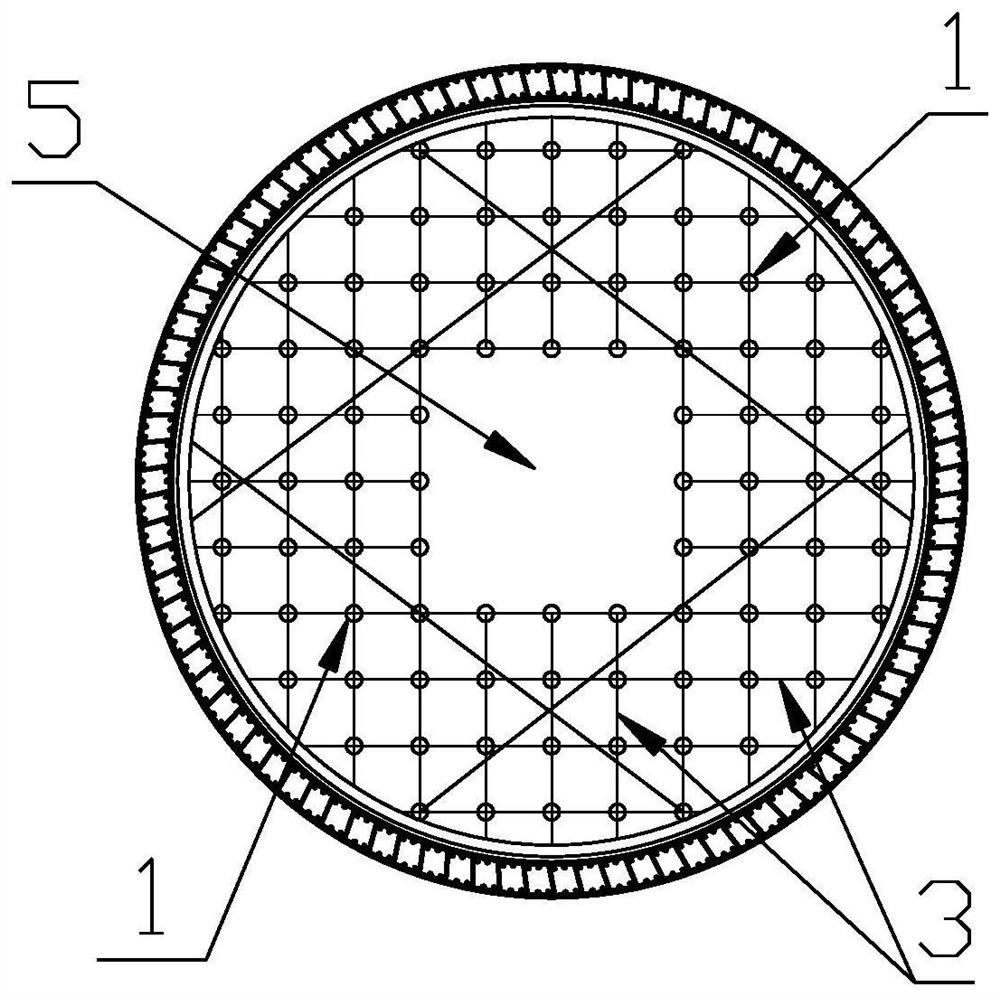

[0031] The total height of the ore warehouse of a chamber unloading system is 36.61m, the elevation of the rail surface of the chamber is 1280.39m, and the floor elevation of the unloading chamber is 1317.00m; The height of the well block section of the ore bin is 3.2m, the height of the clearance diameter of 9m is 8.735m, and the height of the lock section between the upper ore bin and the unloading chamber is 3.0m. The construction of the wall seat section of the ore bin is 11.935m below the unloading chamber floor elevation of 1317.00m, the excavation section gradually changes from a diameter of 10.8m to a diameter of 14.2m, a gradient height of 1.7m, and a section height of 14.2m in diameter of 1.5m.

[0032] According to the construction progress of the above-mentioned chamber unloading system ore warehouse, scaffolding is gradually erected from bottom to top to form a formwork frame. The process of erecting scaffolding is as follows:

[0033] S1, construction preparation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com