Gas-driven packer and packer setting method

A gas-driven, packer technology, used in sealing/packing, earthmoving, wellbore/well components, etc., can solve problems such as stuck drilling, well wall collapse, long construction period, etc. Maintain full-bore effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0028] The invention provides a gas-driven packer and a packer setting method, figure 1 As the technical roadmap of this method, the method includes the following steps:

[0029] S100. Packer setting technology under the condition of full wellbore gas phase medium;

[0030] S101. The gas-driven packer setting technology is characterized in that: when a gas layer is encountered during gas drilling and a midway test is required, there is no need to replace the gas-phase medium in the wellbore with a liquid-phase medium, and there is no need to replace the gas-phase medium in the wellbore after the test is over. The liquid is replaced with gas and the wellbore is dried.

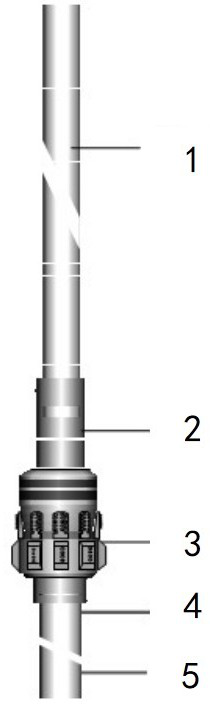

[0031] S200, gas-driven setting packer, including anchoring-release mechanism 2, gas-driven setting packer main body 3, milling-unsealing mechanism 4, shear pin type setting blind 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com