Diaphragm compressor diaphragm pulsation system fault diagnosis device based on industrial internet platform

A fault diagnosis device and diaphragm compressor technology, which is applied in the direction of machines/engines, pumps with flexible working elements, mechanical equipment, etc., can solve the problem of untimely hydraulic oil replenishment, loss of working ability, stress increase of diaphragm and related components Large and other problems, to achieve the effect of easy installation, convenient operation, objective and accurate working status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

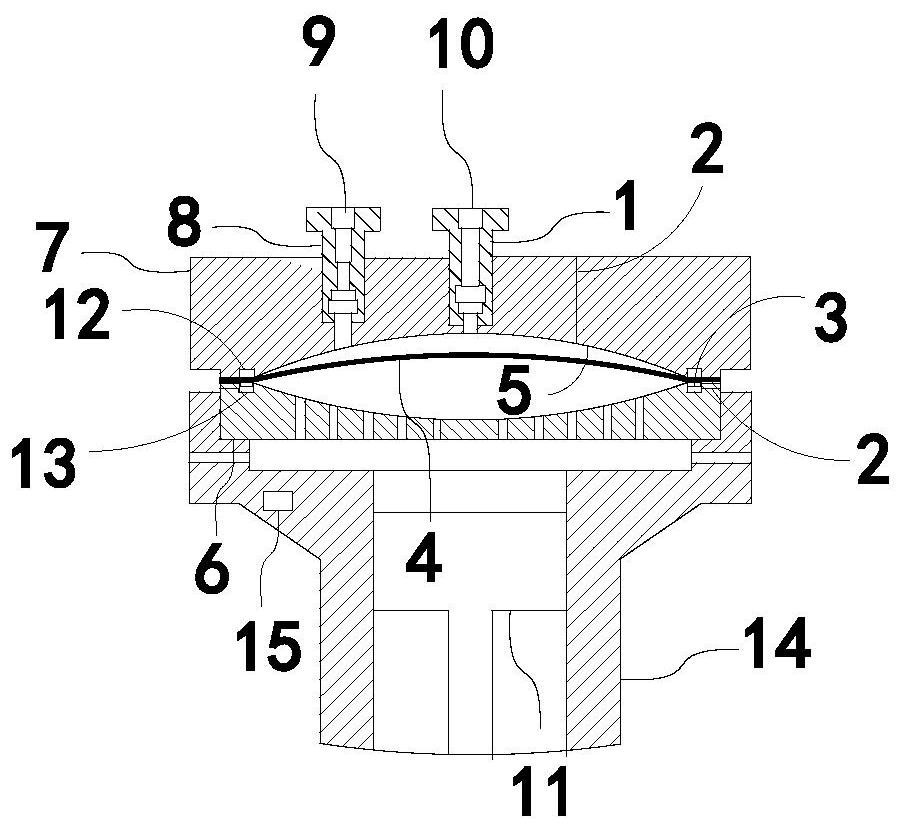

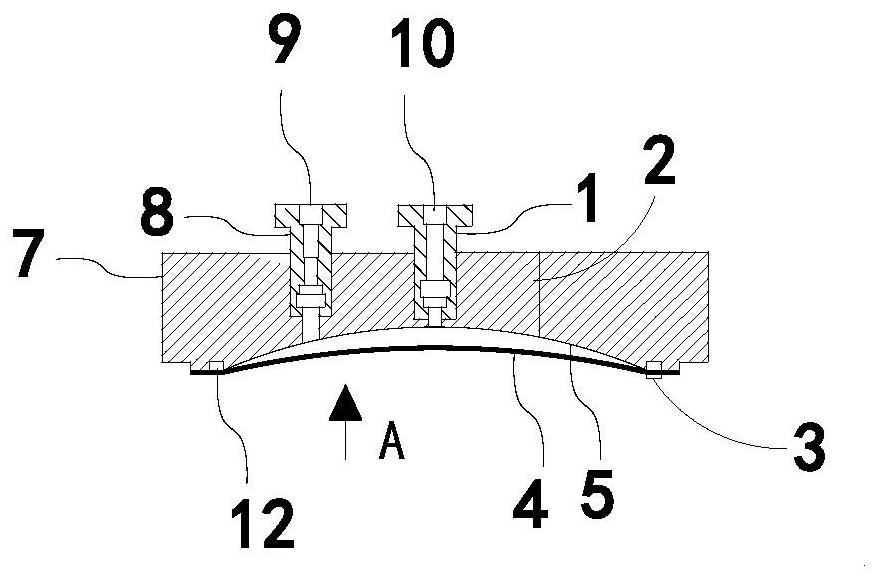

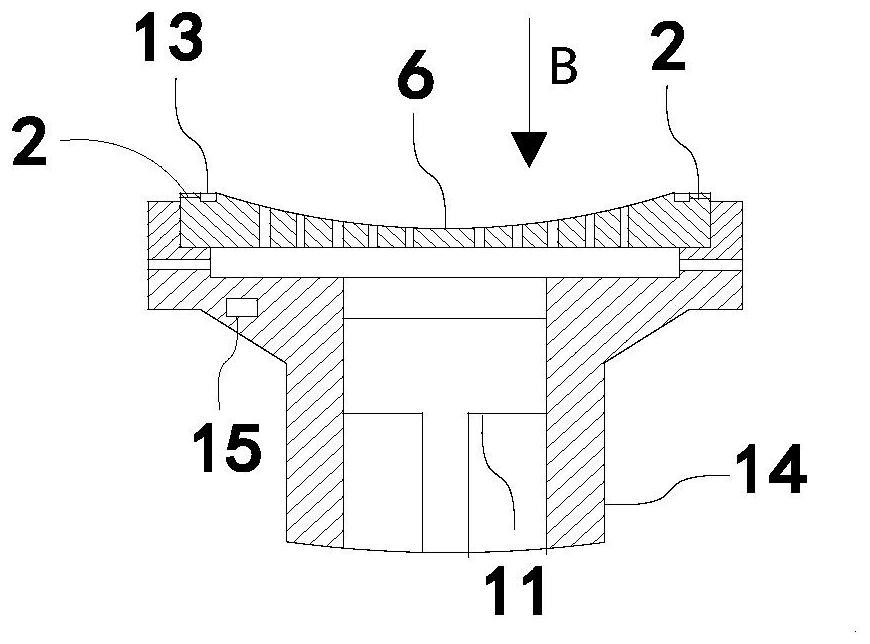

[0032] like figure 1 As shown, the diagnosis device of the diaphragm diagnosis device based on the industrial Internet platform, including the cylinder 14, the oil distribution pan 6, the cylinder head 7, the cover plate 5, the diaphragm 4, and the piston 11; the cylinder cover 7 is fixed It is provided above the oil distribution plate 6 and forms a working chamber between each other; the diaphragm 4 is disposed laterally in the working chamber, and the working chamber is divided into a gas phase working chamber and a liquid phase working chamber; the cover plate 5 is fixed to the top of the gas phase working chamber; the intake valve 8 and the exhaust valve 1 are respectively provided at the top of the cylinder head 7; the air valve 8 and the exhaust valve 1 are in communication with the gas phase working chamber, respectively; The liquid phase working chamber is in communication with the oil passage of the oil tray 6 to the liquid working chamber within the cylinder 14;

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com