FPC line scanning AOI platform

A line scanning and platform technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of low storage efficiency, large footprint, slow switching models, etc., to achieve the optimization of plane space layout, The effect of improving operation efficiency and optimizing operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

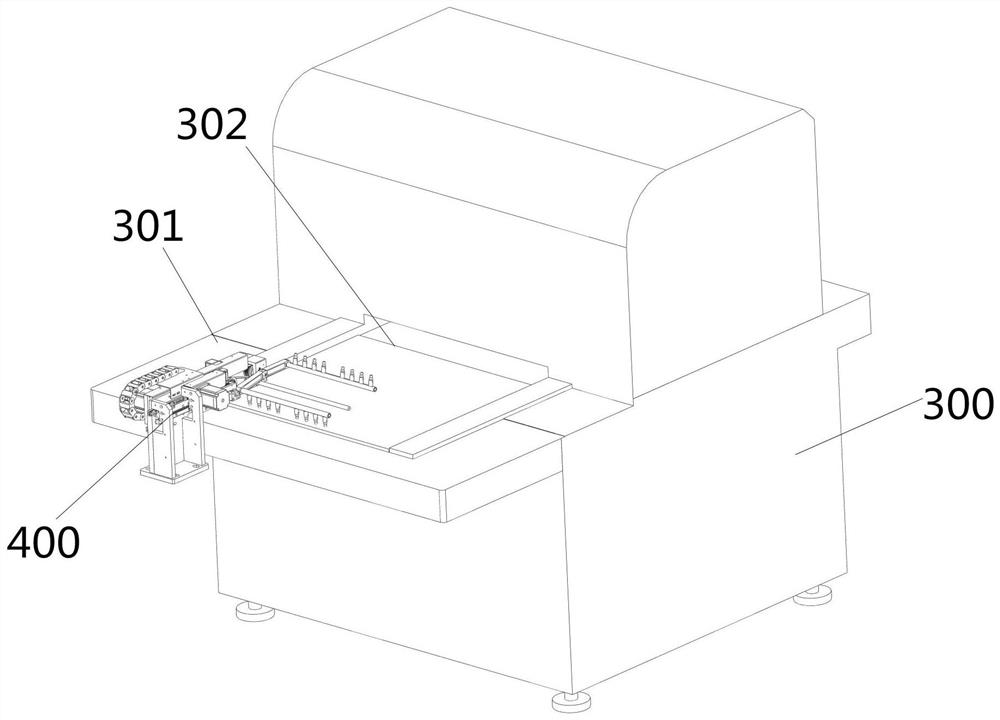

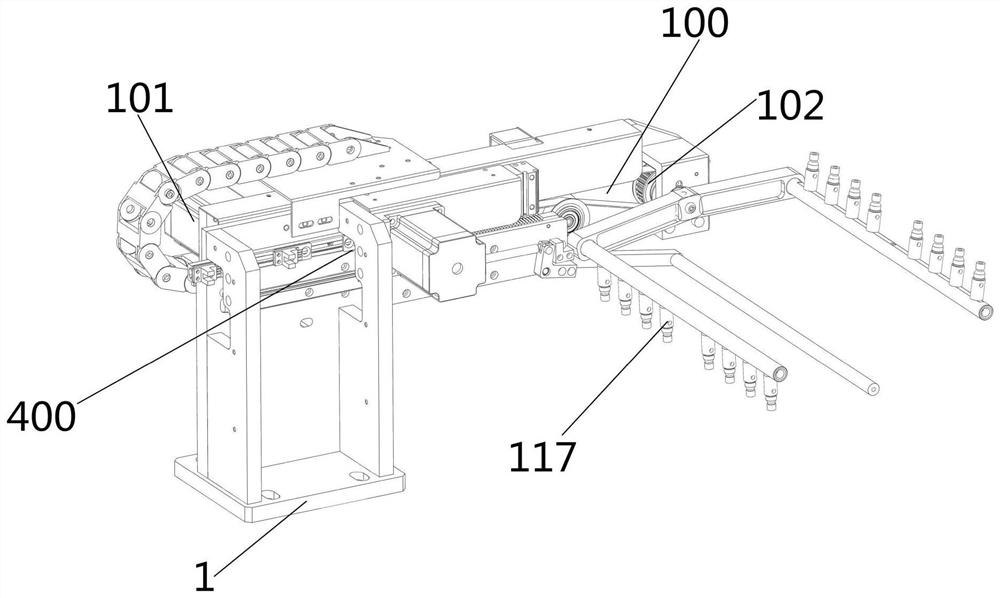

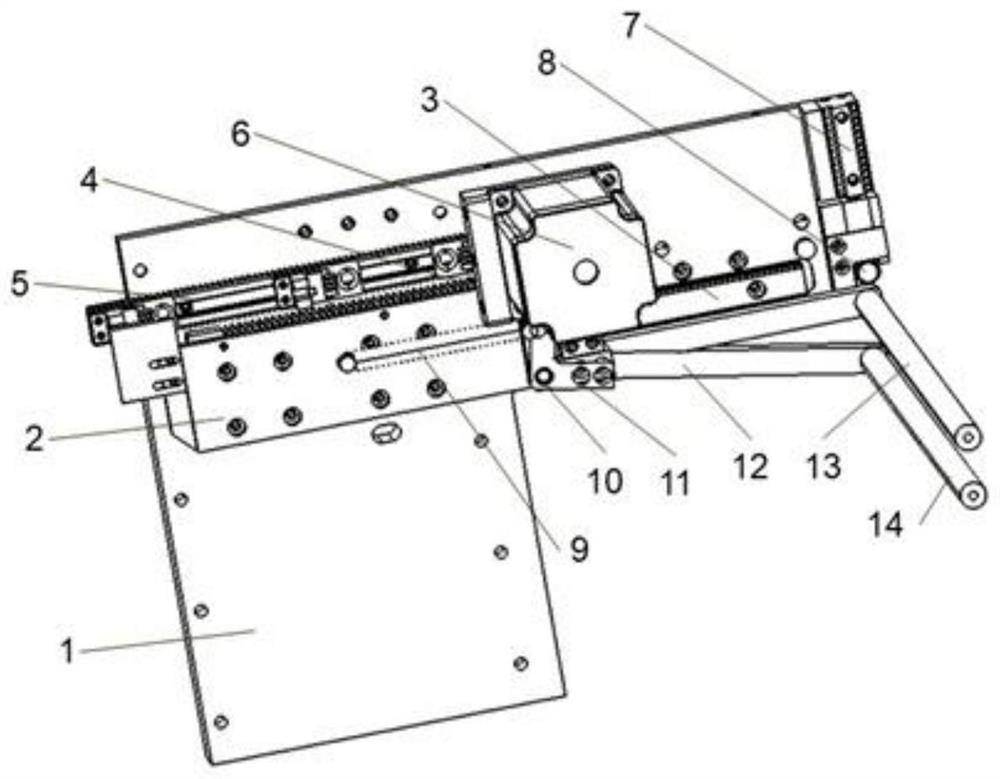

[0031] Such as Figure 1-4 A FPC line scanning AOI platform shown includes:

[0032] Machine main body 300, described machine main body 300 is provided with AOI table top 301, and described AOI table top 301 is used for placing and scanning FPC, and AOI table top 301 is provided with limit bar 302;

[0033] Turn over robot 400, described turn over robot 400 is fixed on the described machine body 300, described turn over robot 400 has suction arm 100 and lever arm 200, and described suction arm 100 has suction arm horizontal moving mechanism 101 and The suction arm rotation mechanism 102, the suction arm rotation mechanism 102 is connected with a plurality of linearly arranged feeding one-way suction cups 117, and the suction arm horizontal moveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com