Machine tool machining waveform matching method and system based on time sequence power data

A matching method and waveform matching technology, applied in the direction of comprehensive factory control, computer parts, instruments, etc., can solve problems such as electric signal detection can not detect problems, machine tool errors, etc., to achieve the effect of easy discovery and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

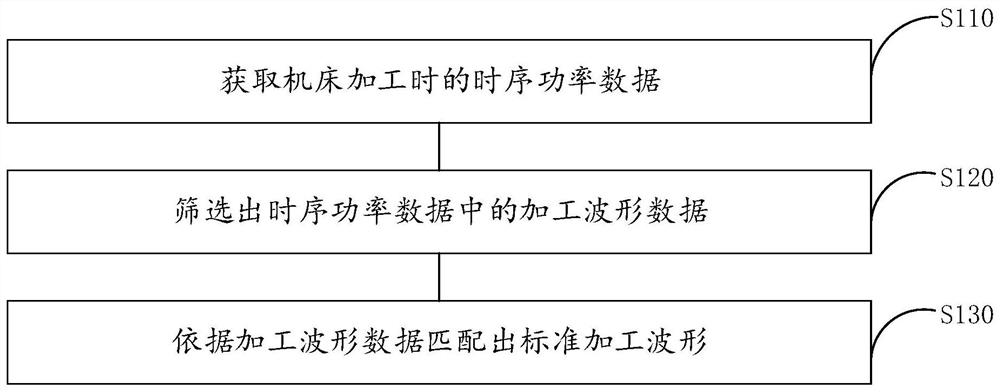

[0043] see figure 1 , this embodiment provides a method for matching machine tool processing waveforms based on time series power data. By converting the sequential power data during machine tool processing into processing waveform data, and matching the standard processing waveform of the corresponding workpiece, the state of the machine tool when producing different workpieces is judged through the standard processing waveform, which improves the accuracy of machine tool monitoring and facilitates Timely discovery of machine tool problems.

[0044] Specifically, the matching method of machine tool processing waveform based on time series power data includes the following steps:

[0045] S110: Obtain time-series power data during machine tool processing;

[0046] Specifically, the acquisition of time-series power data during machine tool processing, that is, the acquisition of time-series power data of the bus on the machine tool through a power sensor.

[0047] S120: Filt...

Embodiment 2

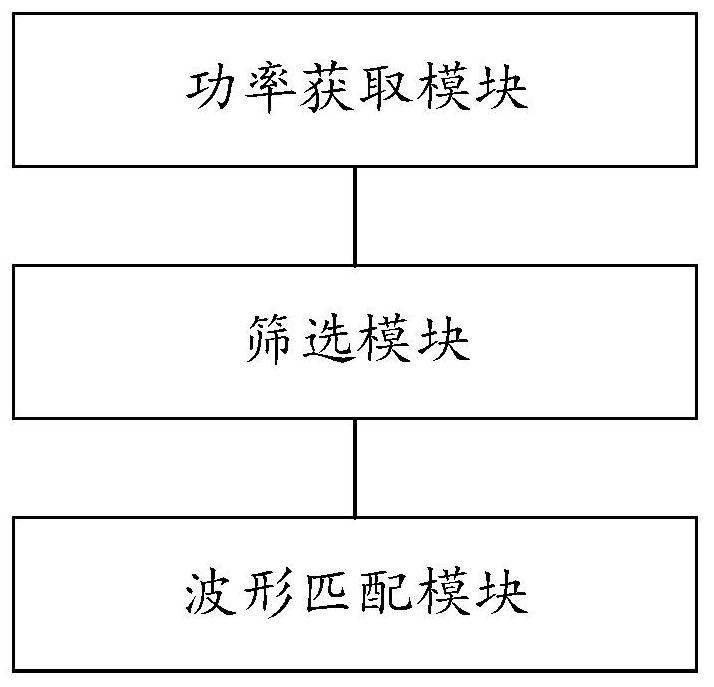

[0065] see figure 2 , the present embodiment provides a matching system for machine tool processing waveforms based on time-series power data, the system comprising:

[0066] The power acquisition module is adapted to acquire time-series power data during machine tool processing; wherein, the power acquisition module includes a power sensor, and the power sensor is adapted to acquire time-series power data of the bus on the machine tool.

[0067] The filtering module is suitable for filtering out the processed waveform data in the time series power data. The screening modules include:

[0068] The screening unit is adapted to filter out the power data greater than the non-processing threshold in the time-series power data; specifically, the upper limit of the power threshold of the bus of the machine tool when it is not processed is the same when different workpieces are produced, so the power threshold is passed The power threshold at the processing moment can be selected....

Embodiment 3

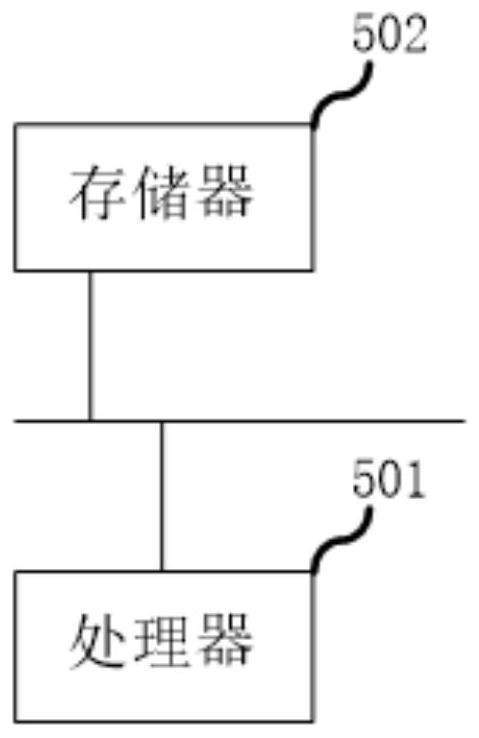

[0079] This embodiment provides a computer-readable storage medium, and one or more instructions are stored in the computer-readable storage medium, and when the one or more instructions are executed by a processor, the timing-based A method for matching machine tool machining waveforms of power data.

[0080] The matching method of machine tool processing waveform based on sequential power data converts the sequential power data during machine tool processing into processing waveform data, and matches the standard processing waveform corresponding to the workpiece, and uses the standard processing waveform to compare the state of the machine tool when producing different workpieces. Judgment improves the accuracy of machine tool monitoring and facilitates the timely discovery of problems existing in the machine tool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com