Fault diagnosis method for medium-voltage modular multilevel converter

A modular multi-level, fault diagnosis technology, applied to the measurement of electrical variables, neural learning methods, instruments, etc., can solve the problem of increasing cost and system complexity, unable to determine the specific location of the fault point, and difficult to establish an accurate mathematical model and other problems, to achieve the effect of increasing system cost and complexity, good diagnostic performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

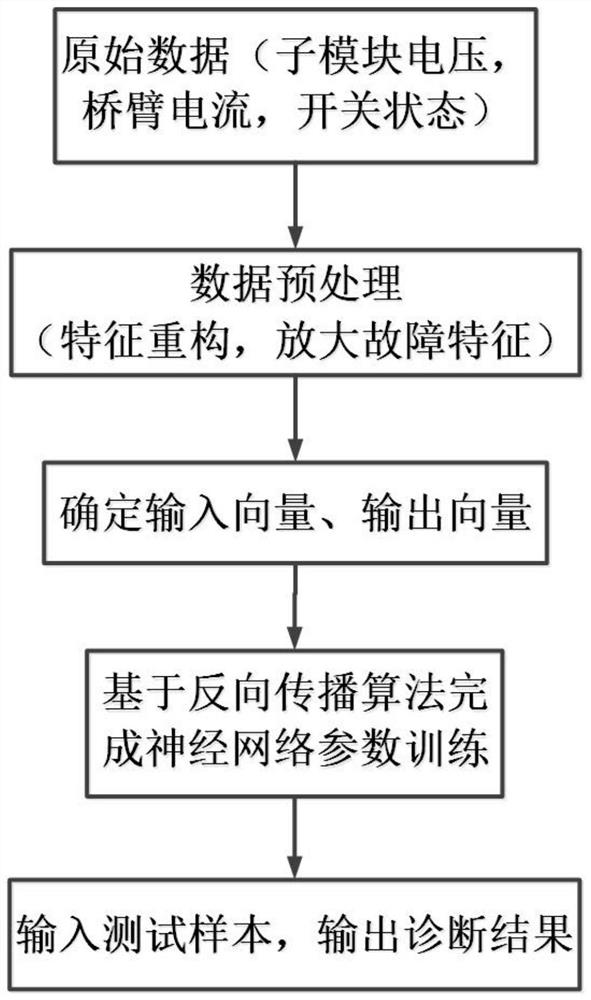

[0036] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

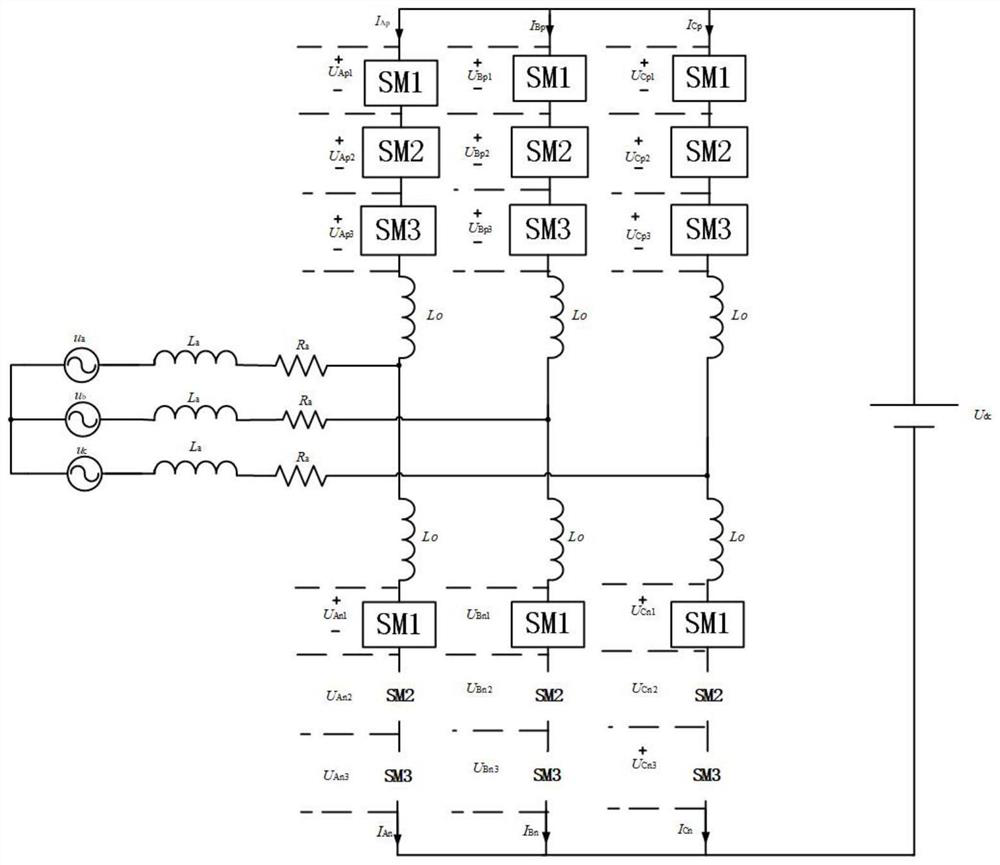

[0037] figure 1 It is the MMC three-phase topology diagram in the embodiment of the present invention, as shown in the figure, the MMC three-phase six bridge arms, each bridge arm has 3 sub-modules (SM) with the same structure and one for limiting the circulation fluctuation The bridge arm inductance composition. where U pji Characterizes the sub-module voltage value of the i-th sub-module of the j-th bridge arm of the p-phase; I pj Characterize the arm current value, L o is the inductance value of the bridge arm, La is the inductance value of the load side, and Ra is the resistance value of the load side.

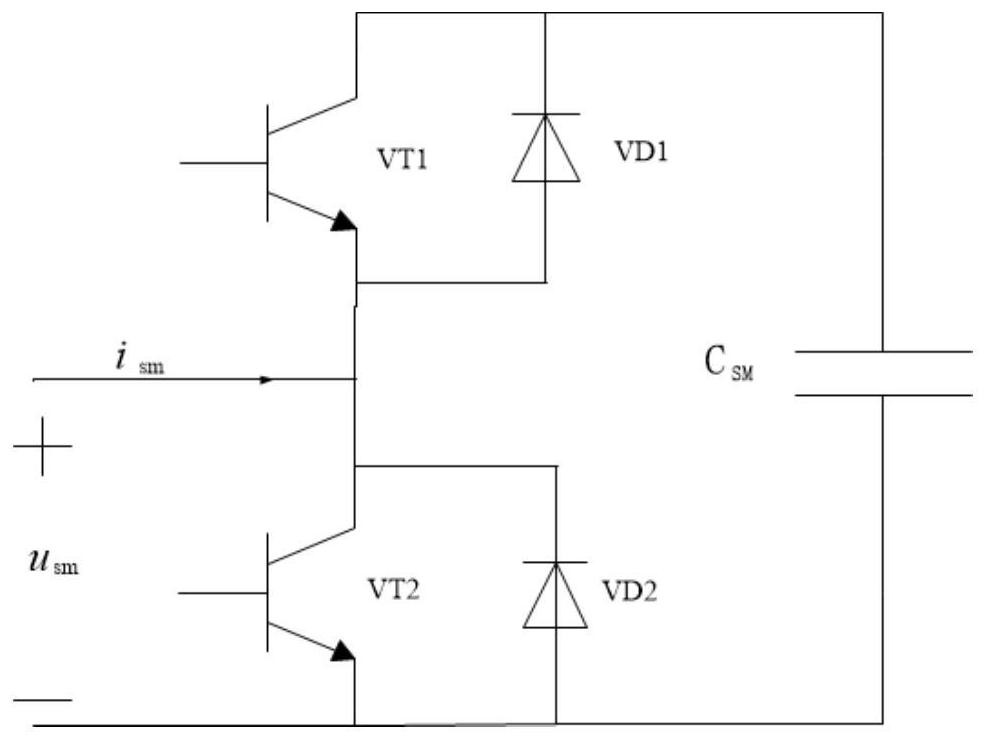

[0038] figure 2 It is a topological structure diagram of the MMC submodule in the embodiment of the present invention. In this embodiment, a half-bridge sub-module is used, such as figure 2 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com