Environment self-adaptive product defect detection method based on whiteboard illumination compensation

A technology for illumination compensation and product defects, which is used in the processing of 3D images, image data processing, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

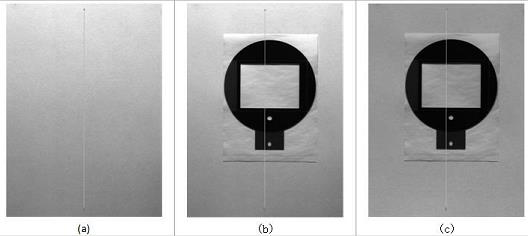

[0022] The implementation process and working principle of the algorithm are described through the following examples. Considering the different application scenarios of the algorithm, in order to improve the final image processing effect, various evolutionary implementation methods can be adopted in each link. This embodiment only shows an implementation process, which is used to illustrate the simplified steps of the method.

[0023] The first step is to collect the light distribution data of the lighting source. The most general implementation method is to place a piece of clean white paper in the blank viewing space, and the white paper occupies the viewing space. Trigger the camera to take pictures when the light source is stable.

[0024] In the second step, replace the white paper in the first step with the sample material to be tested, and the collection method is consistent with the above steps. This embodiment is a simplified version of the implementation process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com