Tool-free linkage locking and pulling device for LRM

A tool-free, linkage technology, applied to elastic/clamping device, circuit arrangement on support structure, component plug-in combination, etc., can solve the problem of not taking into account the electronic module locking and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

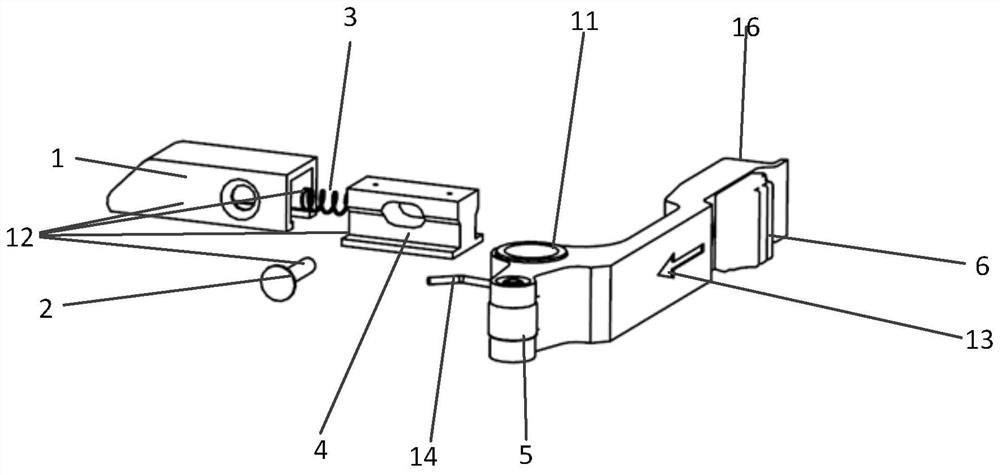

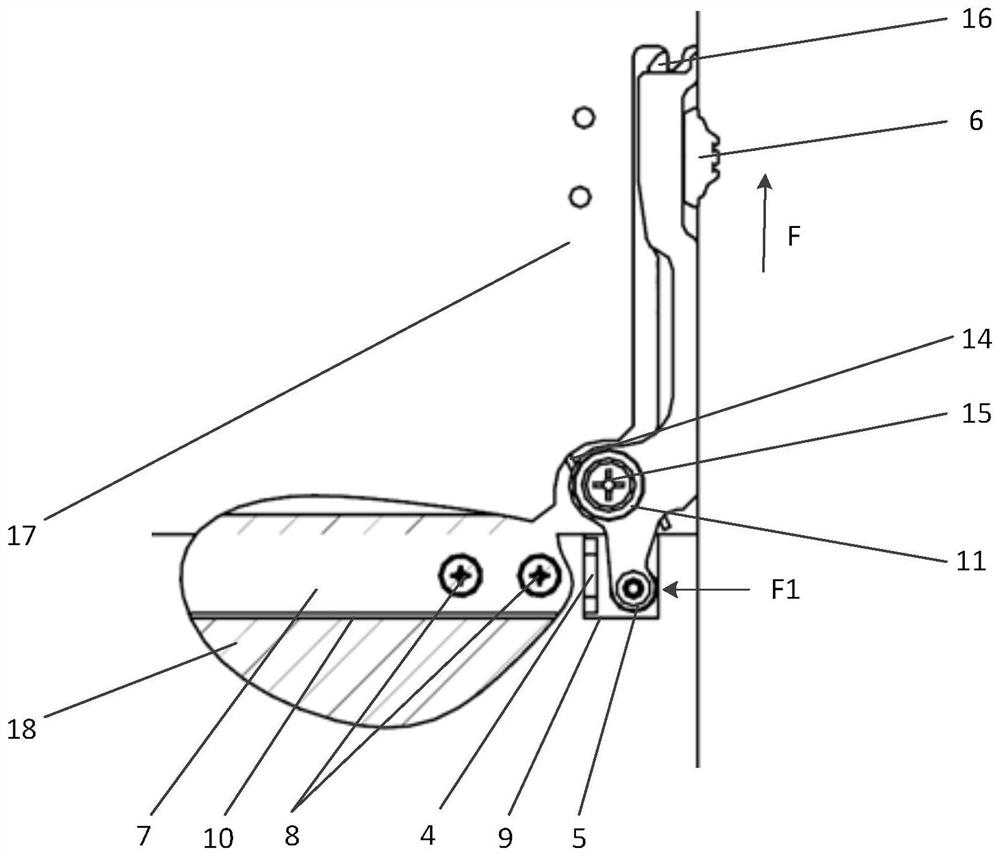

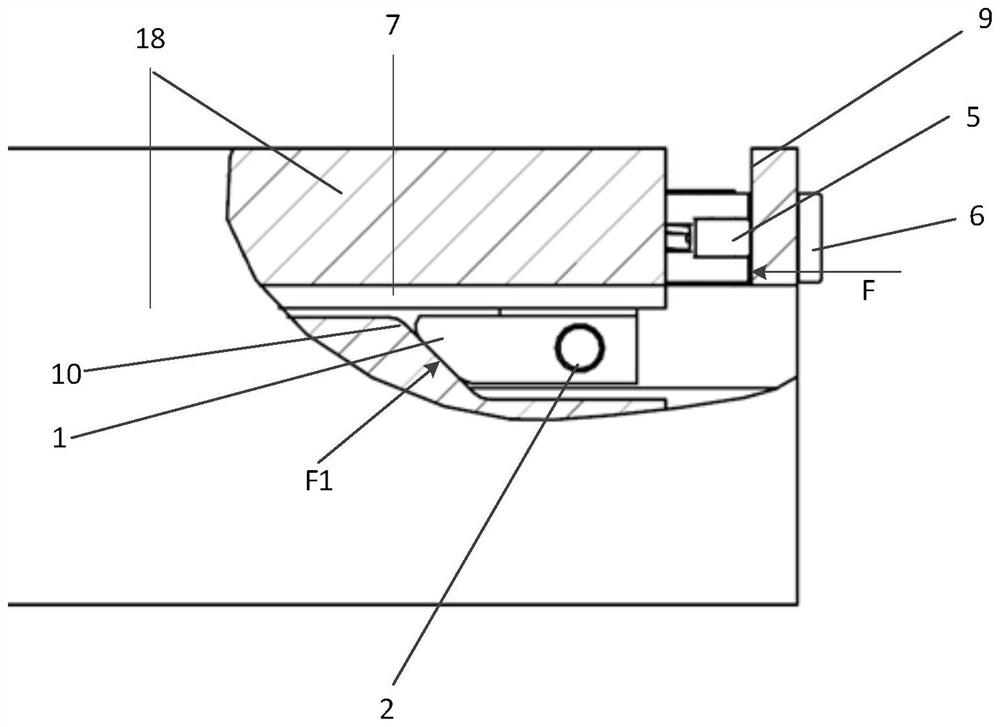

[0021] refer to Figure 1-Figure 3 . In the preferred embodiment described below, a tool-free interlocking locking and pulling device for an LRM module includes: a countersunk screw 15 is inserted into the fork trunnion hole 11, and is fixedly connected to the rib 7 of the LRM module chassis on the lug rotation pair. The spring lock tongue 16 and the lifting rocker handle 13 are set on the elbow lug of the lifting rocker handle 13 and inserted into the roller 5 in the pulling groove 9 of the LRM module chassis, and are fixedly connected to the hole end on one side of the elbow lug. The shift fork 14 is connected to the locker 12 formed by the return spring 3 and the slide block 4 by means of the thrust of the rotating pair of the rocker handle 13 . The spring lock tongue 16 is connected to the rib 7 of the LRM module chassis through the pull-out block 6 on the tail end of the rocker handle 13. Under the action of external force F, the spring lock tongue 16 is linked along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com