Gear shaping type air cooling radiator

A radiator and air-cooling technology, applied in cooling/ventilation/heating transformation, modification through conduction heat transfer, electrical components, etc., can solve the problems of low heat dissipation efficiency and short production cycle, and achieve improved reliability and efficient heat dissipation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

[0015] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the examples and accompanying drawings. The examples are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

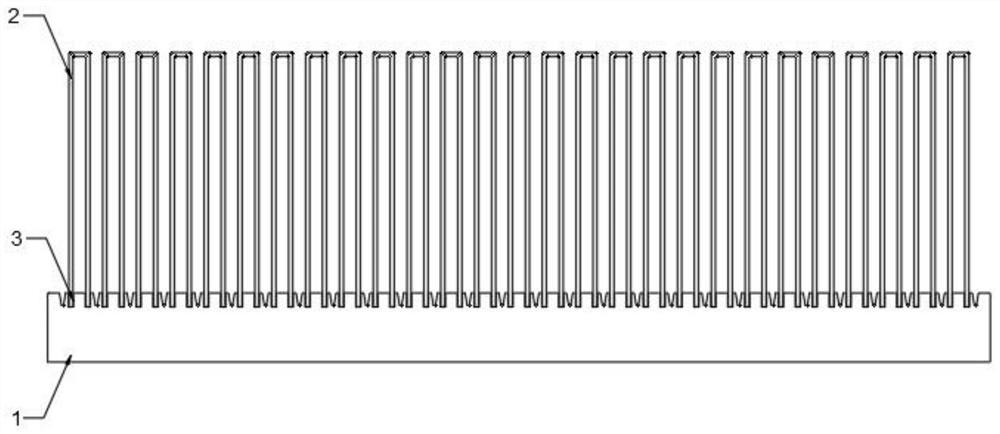

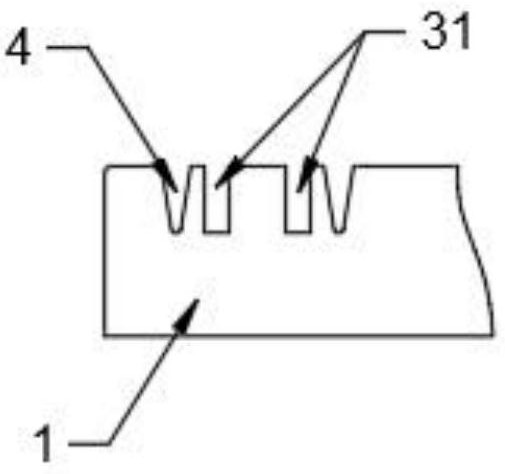

[0016] Such as figure 1 and figure 2 As shown, a pin-type air-cooled radiator includes a base plate 1 and a U-shaped gear piece 2, and the base plate 1 is provided with several evenly distributed pin-shaped assemblies 3, and the described pin-shaped assembly 3 includes two Left and right symmetrical tooth piece grooves 31, the U-shaped tooth piece 2 and the base plate 1 are connected through the tooth piece groove 31, and the U-shaped tooth piece 2 is provided with an annular closed air duct.

[0017] In order to reduce the production cost of the pin-shaped air-cooled radiator and ensure high productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com