Bidirectional simultaneous rotary blade bundle for mixer

A technology of rotating blades and mixers, applied in mixer accessories, mixers with rotating mixing devices, applications, etc., can solve the problems of rotation effectiveness, rotation stability and reliability, increase in blade bundle volume, increase in the number of assembly processes, etc. problems, to achieve the effect of reducing the number of parts and assembly processes, reducing manufacturing costs, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

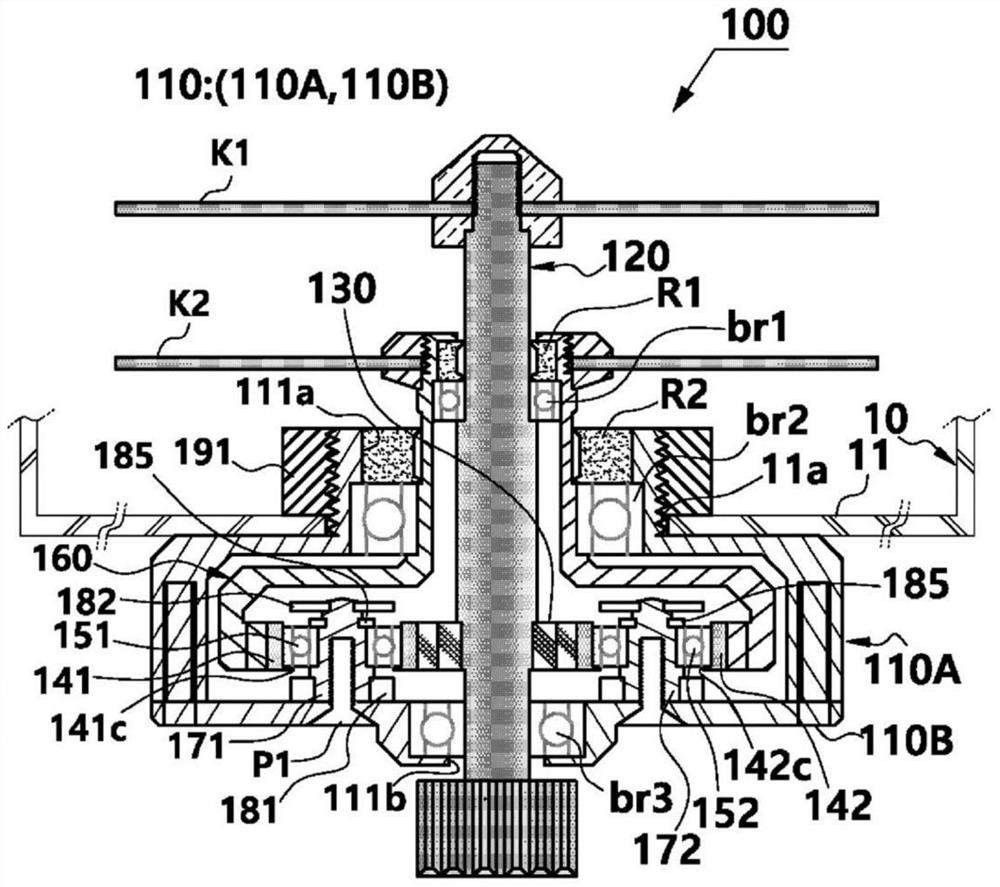

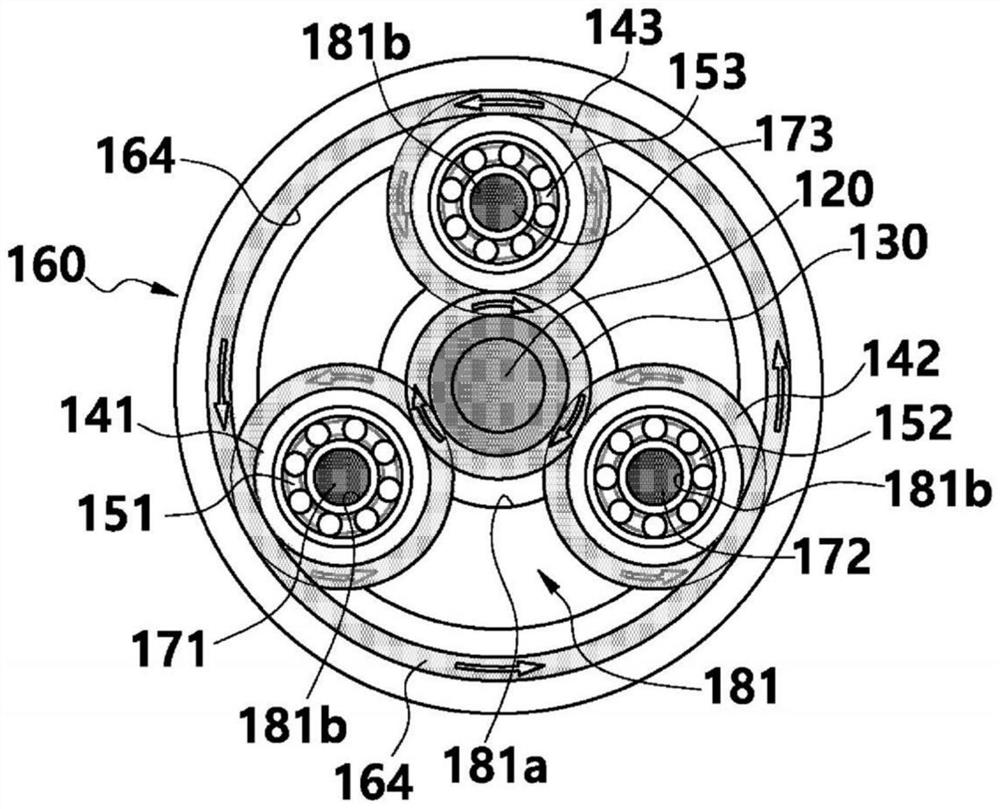

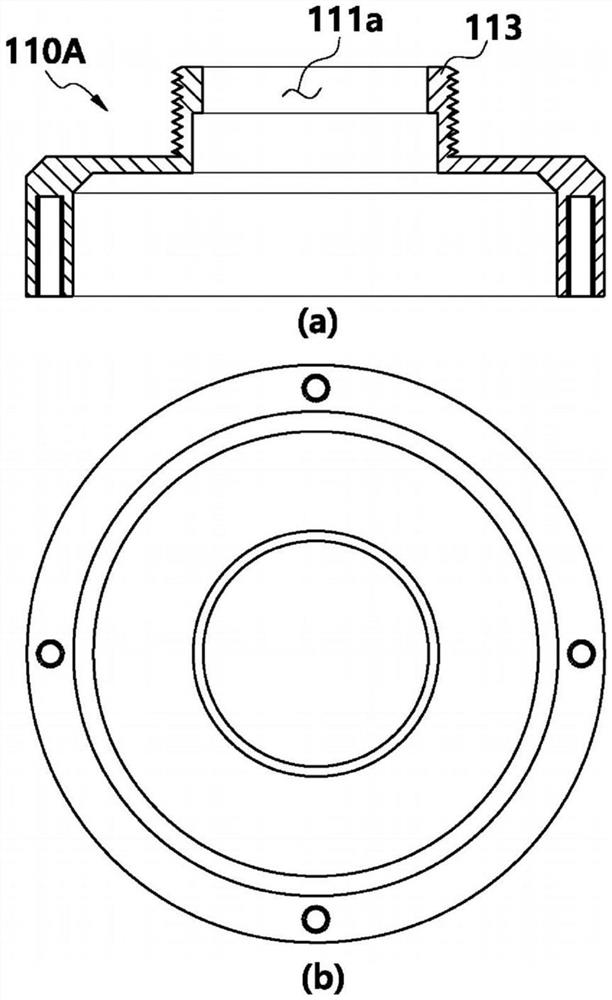

[0036] Hereinafter, preferred embodiments of the bidirectional simultaneous rotating blade bundle for a mixer of the present invention will be described in detail with reference to the drawings.

[0037]The present invention relates to a blender, and the blender includes: a cylindrical container 10 for holding food such as fruits, meat, vegetables, coffee, grains, etc.; Combination; motor (not shown), built in the motor housing (not shown), so as to be able to rotate inside the motor housing; and the blade bundle 100, receiving the rotational force of the motor, rotating according to the rotation of the motor to cut , crushing, grinding the food in the container 10, especially, the present invention relates to the blade bundle 100 as the core structure of the blender.

[0038] The container, the motor housing, and the motor itself are known structures before the application of the present invention, and therefore, detailed description thereof will be omitted.

[0039] As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com