Batch cleaning machine for plush artware

A technology for batch cleaning and handicrafts, applied in the direction of dryers, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the inconvenience of opening and closing to take plush handicrafts, insufficient cleaning and rotation stability, and inconvenience of directly adding cleaning agents and other issues, to achieve high environmental performance, high sealing performance, easy to open or close the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

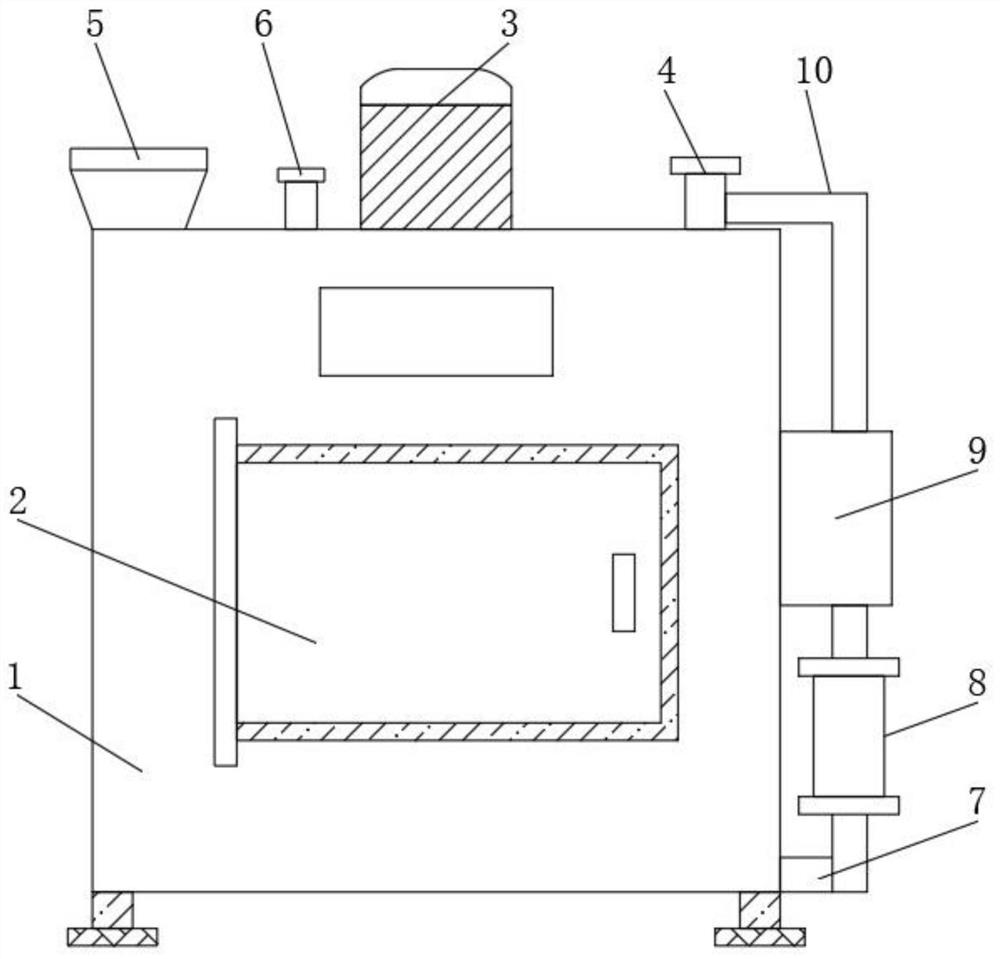

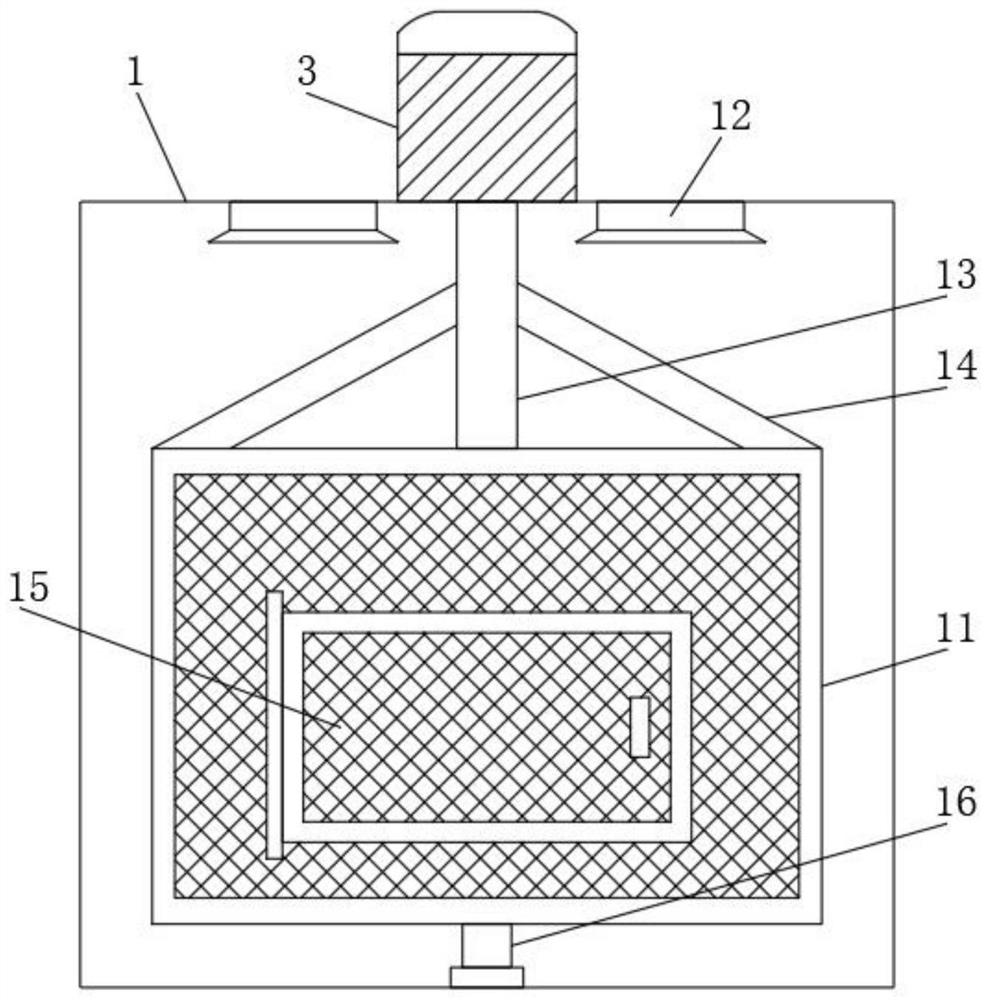

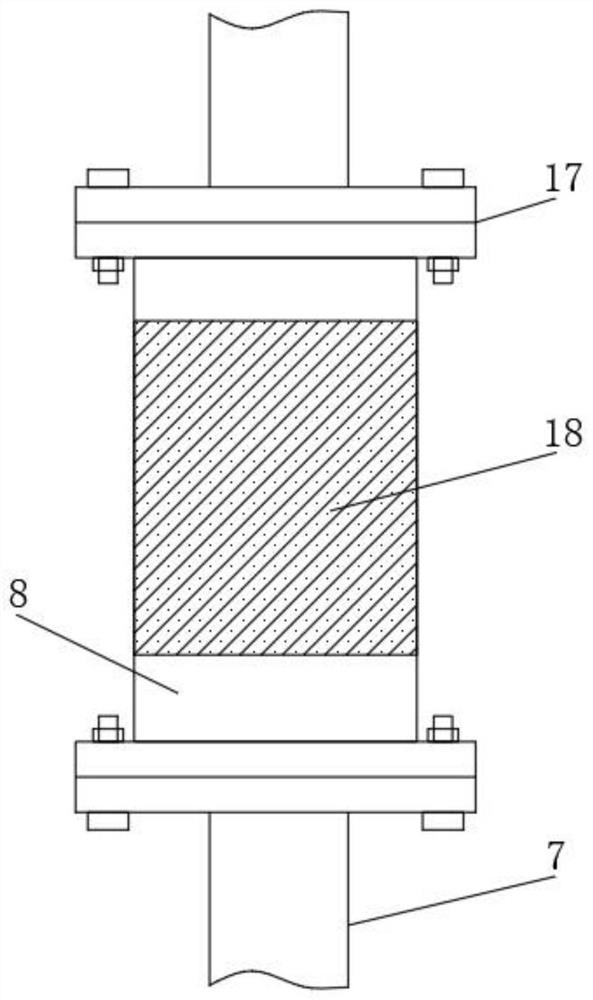

[0026] Such as Figure 1 to Figure 4 As shown, a batch cleaning machine for plush crafts described in this embodiment includes a cleaning machine body 1, a sealed door 2, a drive motor 3, a water inlet 4, a cleaning agent addition port 5, an air inlet 6 and a sewage pipe 7, The top left end of the cleaning machine body 1 is provided with a cleaning agent adding port 5, the top middle of the cleaning machine body 1 is provided with a driving motor 3, the front end of the cleaning machine body 1 is provided with a sealing door 2, and the cleaning machine The top right end of the main body 1 is provided with a water inlet 4, and the bottom right end of the washing machine body 1 is provided with a sewage pipe 7, and the upper end of the top of the sewage pipe 7 is connected with a filter device 8 through a flange 17, and the filter device 8 A precision filter element 18 is provided inside the filter device 8, and a circulating water pump 9 is connected to the top of the filtering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com