Supporting iron numerical control integrated forming machine

A forming machine and supporting iron technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of increased processing costs, wear of equipment parts, frequent wear of punches, etc., to achieve improved quality, improved efficiency, Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

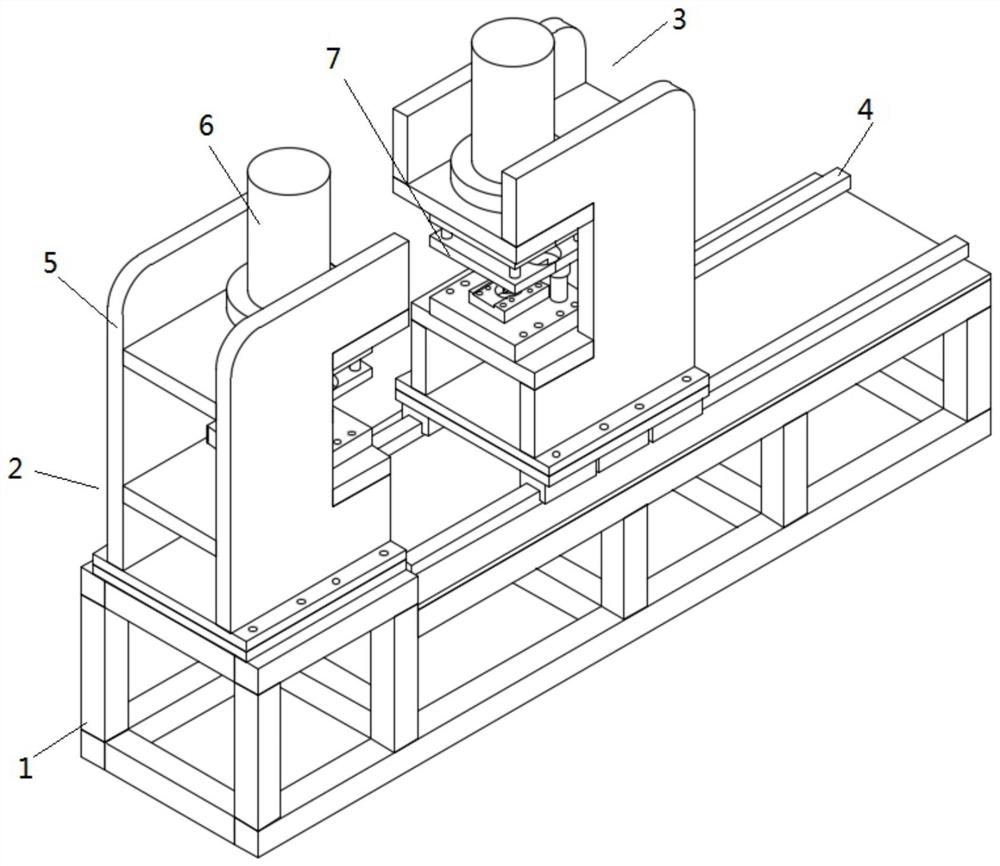

[0022] In an optimized embodiment, the moving direction of the second hydraulic mechanism 3 is toward one side of the composite mold 7 of the first hydraulic mechanism 2 .

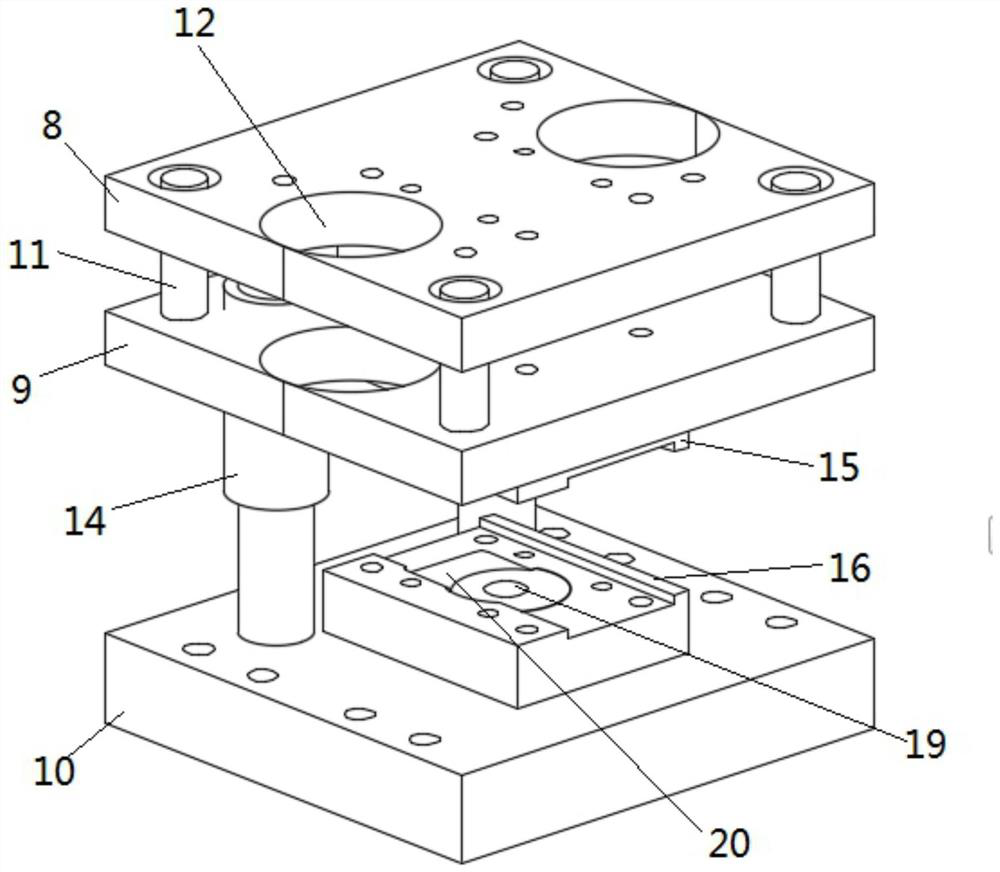

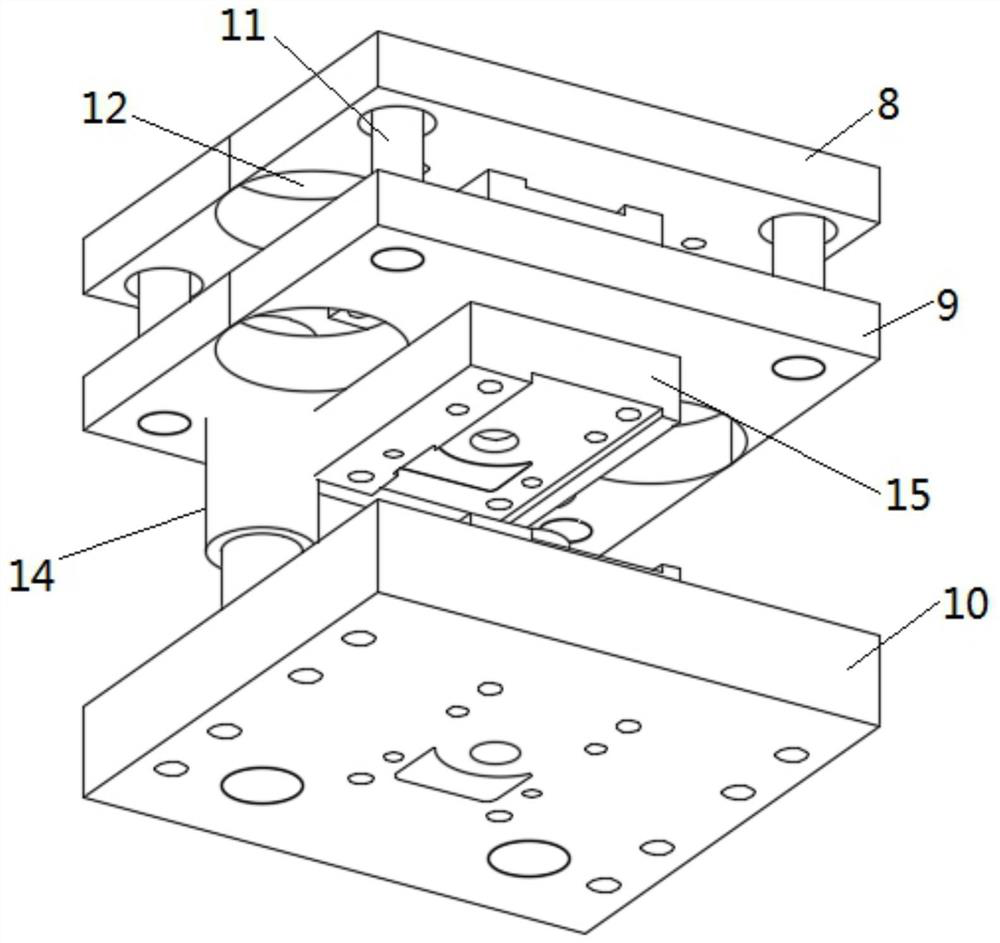

[0023] In an optimized embodiment, the composite mold 7 includes an upper plate 8, a middle plate 9 and a lower plate 10, the lower plate 10 is arranged on the hydraulic main frame 5, the upper plate 8 is connected to the hydraulic cylinder 6, The middle plate 9 is arranged between the upper plate 8 and the lower plate 10, and the four corners of the upper plate 8 and the middle plate 9 are connected with four positioning guide posts 11, and the positioning guide posts 11 passes through the upper plate 8, the upper plate 8 and the lower plate 9 are respectively provided with through holes 12, the through hole 12 of the upper plate 8 and the through hole 12 of the lower plate 9 There is a spring 13 between them. After the hydraulic oil cylinder is started, it will exert pressure on the upper plate. This pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com