Semiconductor automatic chip loading mechanism and operation method

An operating method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of labor and time-consuming, low efficiency of manual loading, and save time, improve production efficiency, and improve the degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

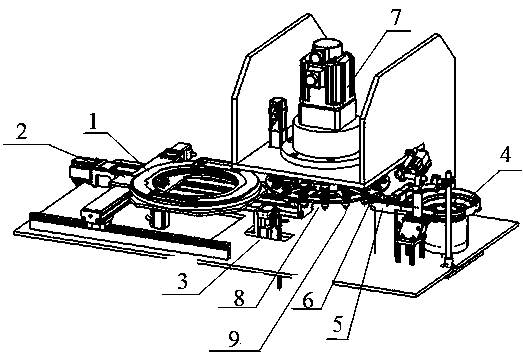

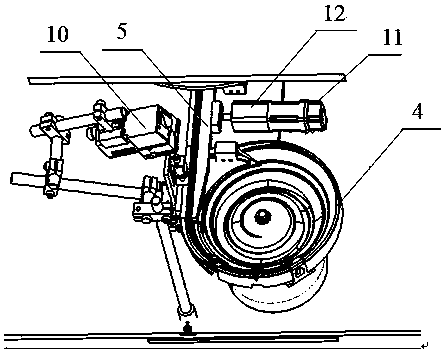

[0024] see Figure 1 to Figure 3 , the present invention relates to a semiconductor automatic chip loading mechanism, which includes a workbench 1, a vibrating plate 4, a guide rail 5, and a turntable mechanism 8. Bulk devices are put into the vibrating plate 4, and the vibrating plate 4 is started, and the bulk devices pass through the vibrating plate in an orderly and orderly manner. 4 The guide rail 5 connected at the end is transferred to the guide rail discharge station 6.

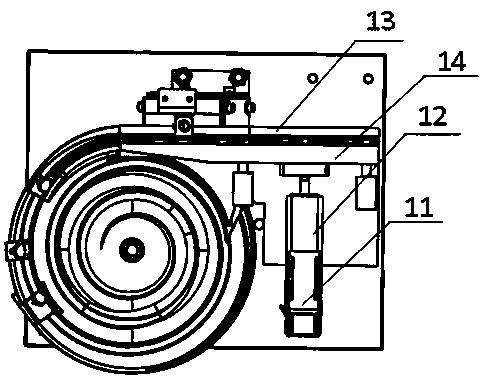

[0025] Wherein guide rail 5 is a track changing guide rail, and it is made up of guide rail fixed end 13 and guide rail movable end 14, and the top of described vibration plate 4 is provided with visual sensor 10, is used for detecting the bulk device of feeding in vibration plate 4, obtains bulk device The size data and the signal of the visual sensor 10 are transmitted to the servo motor 11, the servo motor 11 drives the cam transmission box 12 to move, the cam transmission box 12 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com