Filler thickness correction control method, device and system

A control method and technology of a control device are applied in the field of ceramic brick presses, which can solve the problems of affecting the quality of brick blanks, leaving traces, and the press being unable to know the real-time position of the distribution mechanism, so as to meet the requirements of thickness adjustment, improve performance, and improve the thickness of brick blanks. Precise effect of deviation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

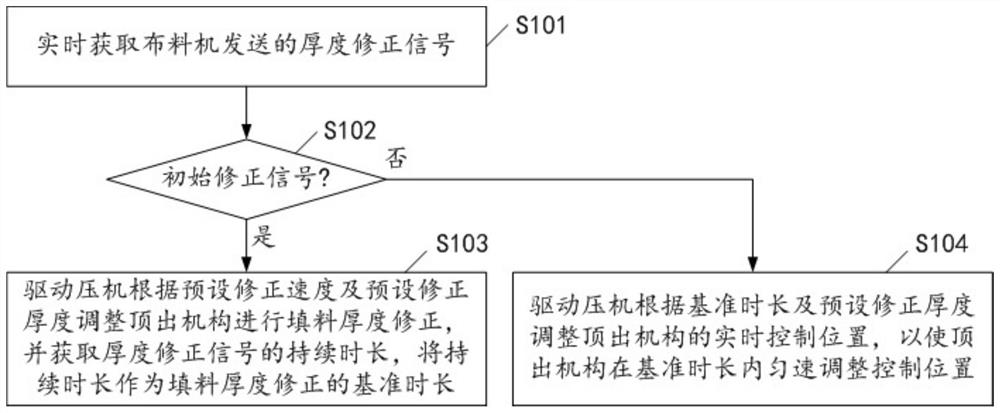

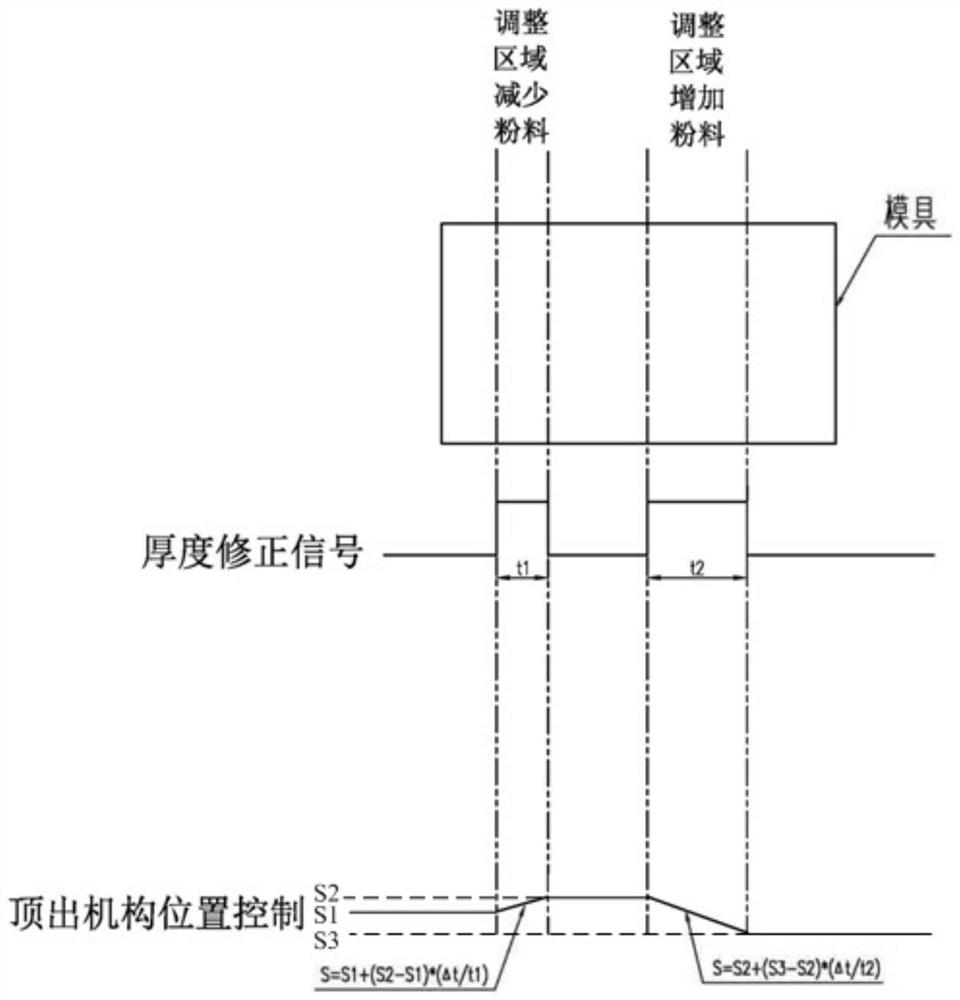

[0024] see figure 2 , figure 2 A flow chart of an embodiment of the filler thickness correction control method of the present invention is shown, which includes:

[0025] S101, acquiring the thickness correction signal sent by the distributing machine in real time.

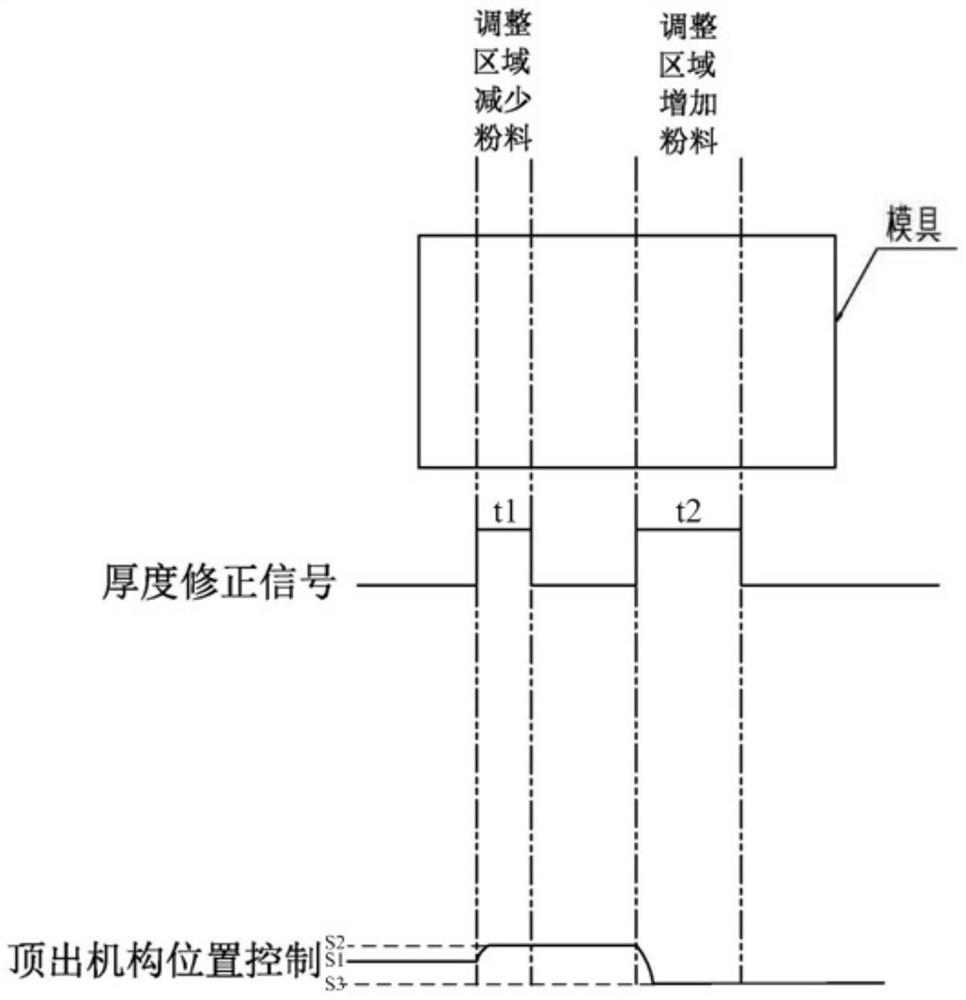

[0026] It should be noted that the current cloth thickness fine-tuning is generally based on the real-time position of the cloth distribution mechanism and the position where powder needs to be increased or decreased by the cloth distribution machine to send a thickness correction signal to the press. Correspondingly, the thickness correction signal is used to indicate that the cloth mechanism needs to perform thickness correction at the current position, and the corrected area range is reflected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com