Vibration mixing device and vibration mixing method for high performance concrete

A high-performance concrete and vibration mixing technology, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of increasing the amount of gel materials, prolonging the mixing time, and improving the concrete, so as to improve the cohesion. , Improve the effect of stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

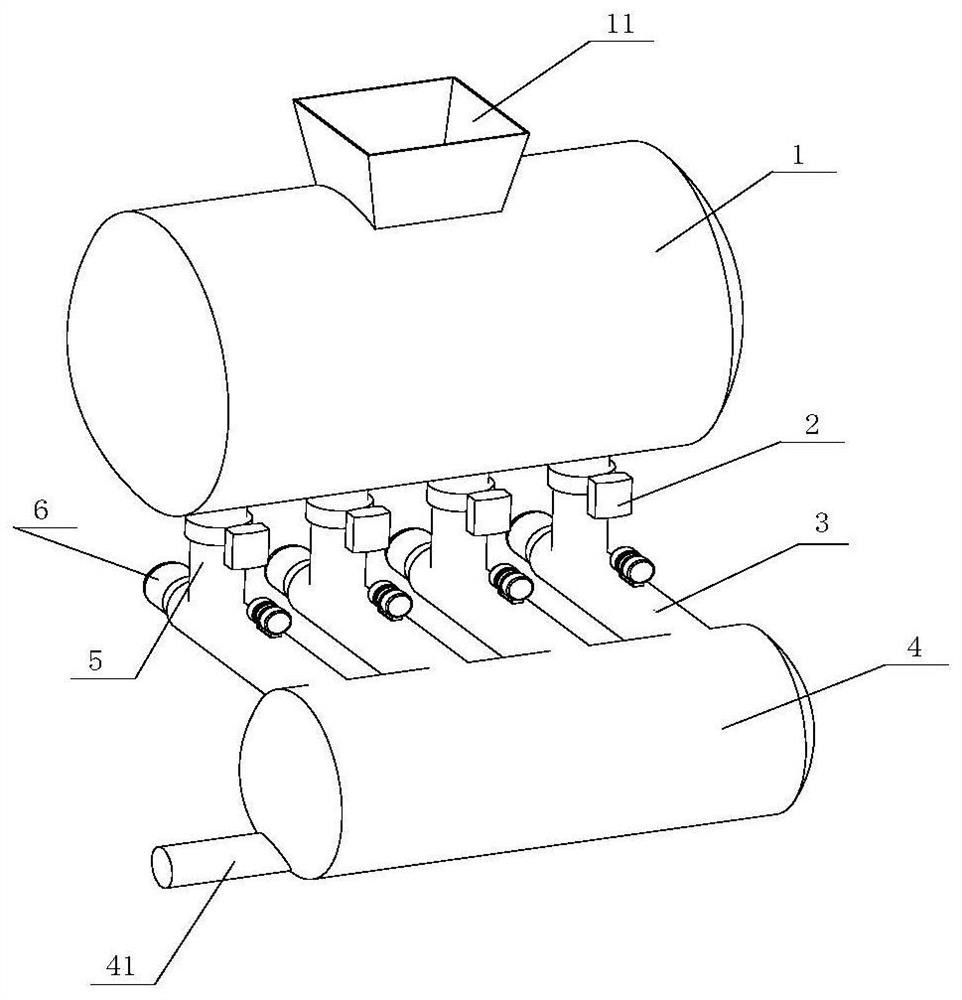

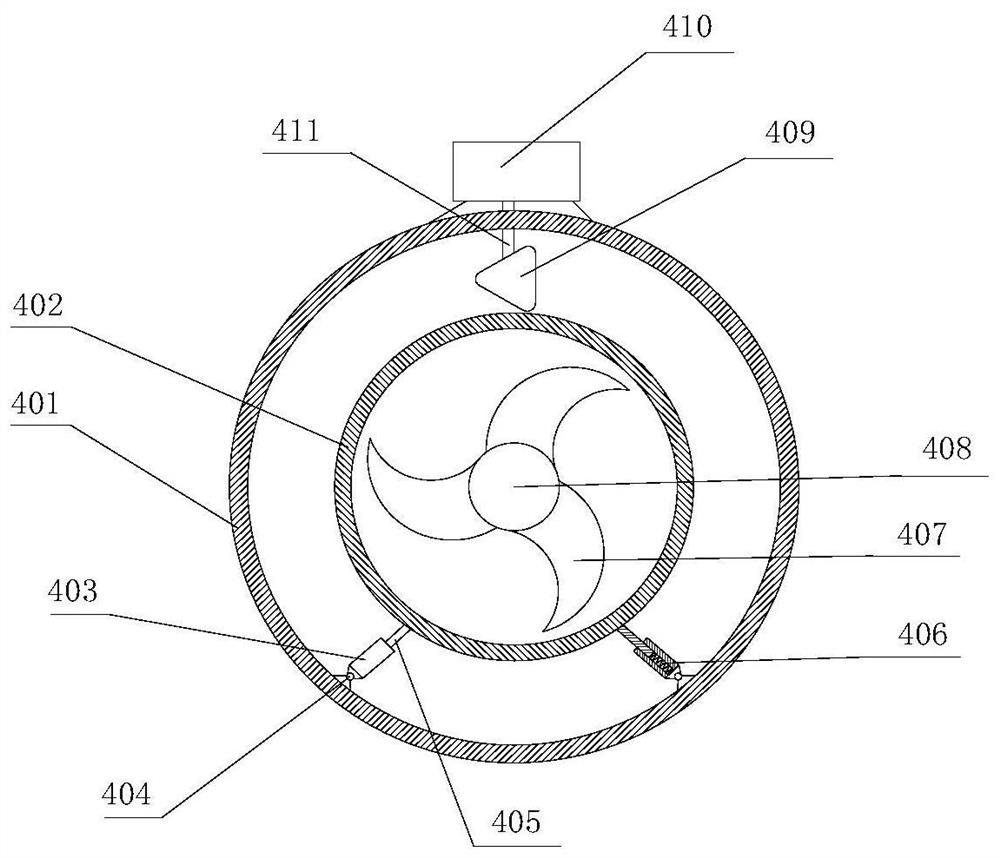

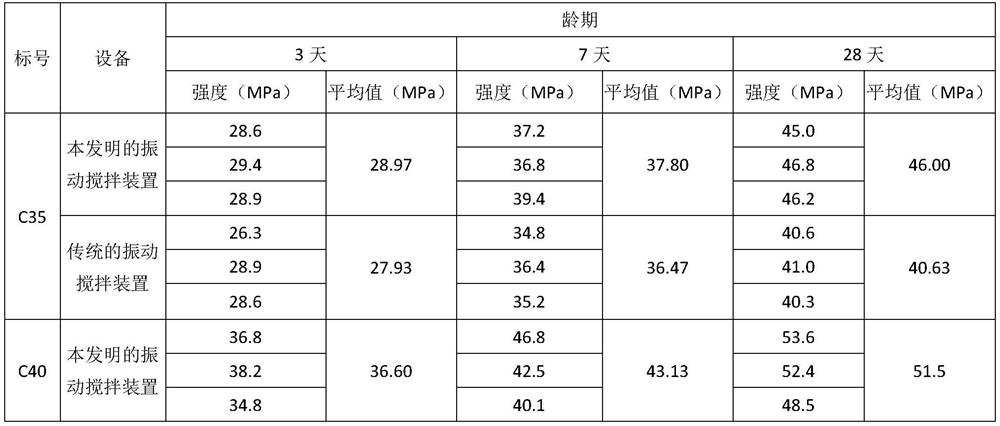

[0040] see Figure 1-Figure 2 , the present embodiment is used for the vibratory stirring device of high-performance concrete, and it comprises primary stirring mechanism, secondary stirring mechanism, stirring and mixing mechanism and feeding pipe 5, and there are 4 secondary stirring mechanisms and feeding pipe 5, and the lower The material pipe 5 is provided with an electric valve on the top, and the electric valve is an electric butterfly valve. The primary stirring mechanism includes a primary coarse stirring chamber 1, a primary stirring part and a primary driving part. The primary stirring part includes a primary transmission shaft and a primary stirring paddle. The primary driving part is Motor, secondary stirring mechanism comprises outer pipe body 401, inner pipe body 402, secondary driving part 6, secondary stirring part, eccentric mechanism and elastic mechanism, secondary driving part 6 is a motor, and secondary stirring part comprises main shaft 408 and Spiral st...

Embodiment 2

[0042] This embodiment is used for the vibratory stirring device of high-performance concrete, which includes a primary stirring mechanism, a secondary stirring mechanism, a stirring and mixing mechanism and a feeding pipe 5, and there are 6 secondary stirring mechanisms and the feeding pipe 5, and the feeding An electric valve is arranged on the pipe 5, the electric valve is an electric ball valve, the primary stirring mechanism includes a primary coarse stirring chamber 1, a primary stirring part and a primary driving part, the primary stirring part includes a primary transmission shaft and a primary stirring paddle, and the primary driving part is an electric The push rod, the secondary stirring mechanism includes an outer pipe body 401, an inner pipe body 402, a secondary driving part 6, a secondary stirring part, an eccentric mechanism and an elastic mechanism, the secondary driving part 6 is an electric push rod, and the secondary stirring part includes The main shaft 408...

Embodiment 3

[0044] The present embodiment is used for the vibration mixing method of high-performance concrete, and it comprises the following steps:

[0045] 1) Add various raw material components for high-performance concrete into the primary rough mixing bin 1 through the feed port 11, the raw material components include cement, mineral admixtures, admixtures, water, sand and ore, and the primary driving parts pass through The primary transmission shaft drives the primary agitating paddle to rotate, and the primary agitating paddle stirs each raw material component, so that the various raw material components of high-performance concrete can fully collide, convect and diffuse, and achieve the macroscopic homogeneity of each raw material component. Stir the slurry;

[0046]2) The primary stirring slurry flows into the inner cavity of the inner pipe body 402 for secondary stirring, and the eccentric wheel driving member 410 drives the eccentric wheel 409 to rotate along the outer wall of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com