Permanent magnet material cutting equipment

A technology for cutting equipment and permanent magnet materials, applied in stone processing equipment, stone processing tools, inductance/transformer/magnet manufacturing, etc., can solve problems such as vibration, high temperature, and material loss of magnetism, so as to prevent loss of magnetism and save resources , Prevent the effect of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

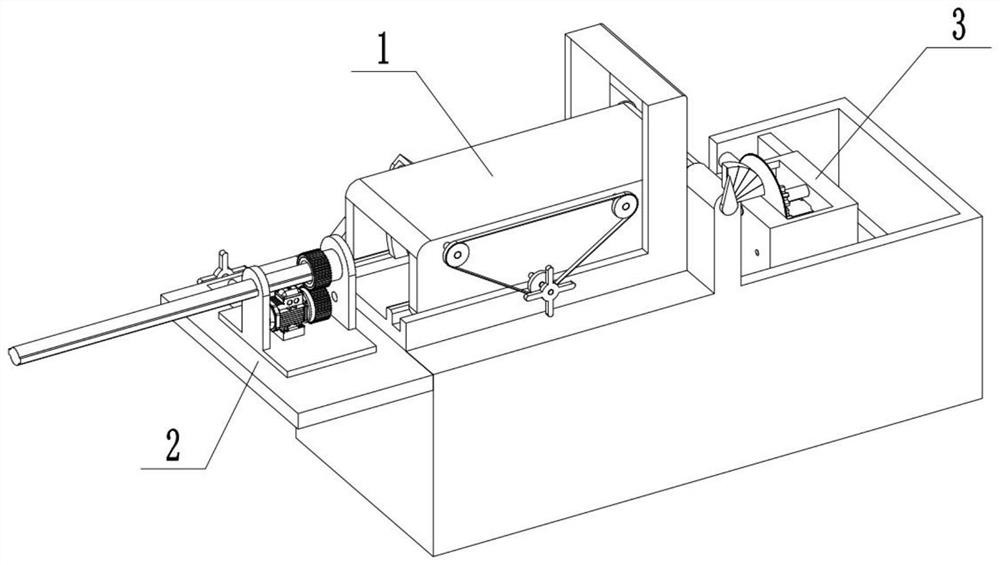

[0028] Combine below Figure 1-12 Describe this embodiment, a permanent magnet material cutting equipment, including a clamping assembly 1, a push-pull assembly 2 and a cutting assembly 3, the push-pull assembly 2, cutting assembly 3 are connected to the clamping assembly 1 .

specific Embodiment approach 2

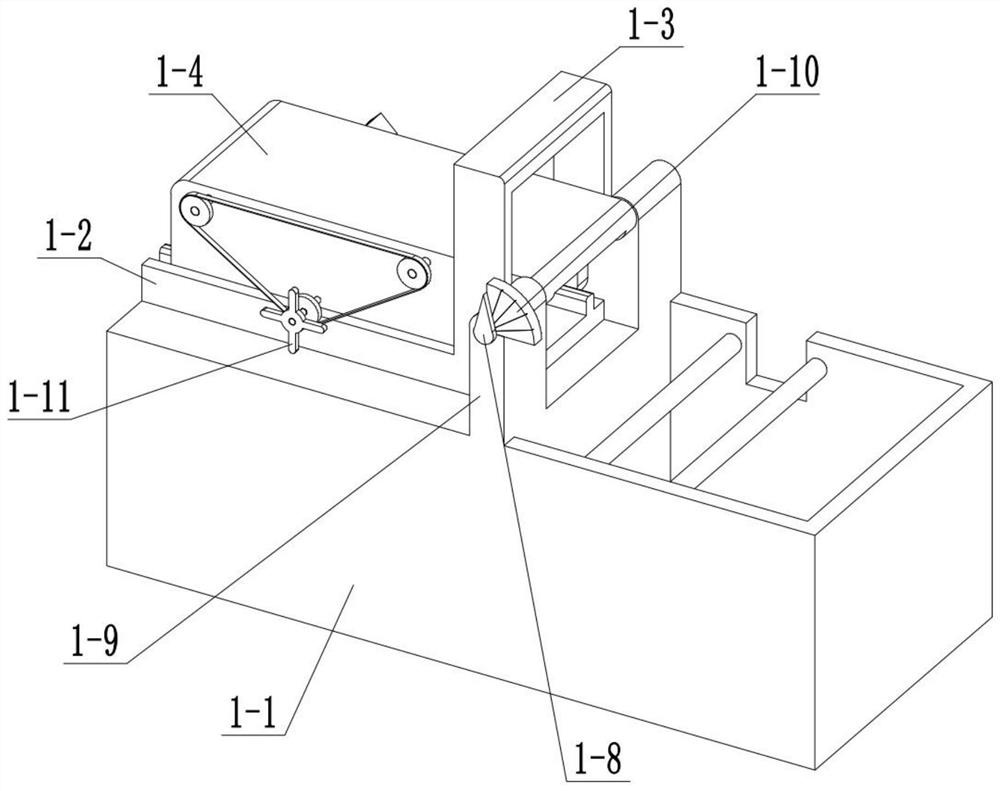

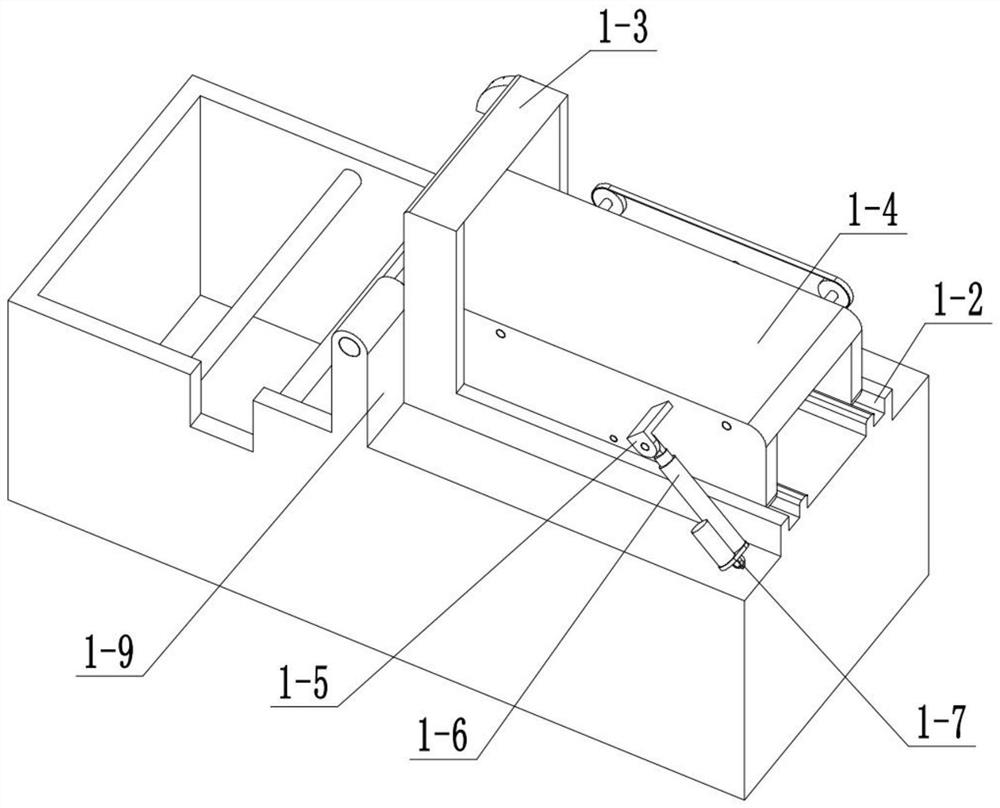

[0030] Combine below Figure 1-12Describe this embodiment, this embodiment will further explain the first embodiment, the clamping assembly 1 includes the equipment shell 1-1, the shockproof bracket I1-2, the shockproof bracket II1-3, the clamp shell 1-4, the electric cylinder support Ear Ⅰ 1-5, electric cylinder 1-6, electric cylinder supporting ear Ⅱ 1-7, turning shaft 1-8, turning supporting lug 1-9, angle plate 1-10, handle Ⅰ 1-11, threaded shaft Ⅰ 1-12, belt Wheel Ⅰ 1-13, belt 1-14, threaded shaft Ⅱ 1-15, fixture Ⅰ 1-16, fixture Ⅰ chute 1-17, fixture Ⅱ 1-18 and fixture Ⅱ slide 1-19, equipment shell 1-1 and shockproof bracket Ⅰ 1 -2 is connected, the anti-vibration support I1-2 is connected with the anti-vibration support II1-3, the equipment shell 1-1 is connected with the flip lug 1-9, the flip lug 1-9 is connected with the angle plate 1-10, and the fixture The shell 1-4 is connected with the turning shaft 1-8, the turning shaft 1-8 is connected with the turning lug 1-9...

specific Embodiment approach 3

[0032] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain Embodiment 1, the push-pull assembly 2 includes a push-pull bottom plate 2-1, a carriage chute 2-2, a handle II 2-3, a threaded shaft III 2-4, and a carriage 2 -5. Push-pull bracket Ⅰ2-6, push-pull bracket Ⅱ2-7, motor 2-8, gear Ⅰ2-9, gear Ⅱ2-10, threaded sleeve 2-11 and push-pull rod 2-12, push-pull bottom plate 2-1 and equipment The shell 1-1 is connected, the carriage chute 2-2 is located in the push-pull bottom plate 2-1, the carriage 2-5 is slidably connected with the carriage chute 2-2, the handle Ⅱ2-3 is connected with the threaded shaft Ⅲ2-4 , the threaded shaft III2-4 is rotationally connected with the push-pull bottom plate 2-1, the threaded shaft III2-4 is threadedly connected with the slide frame 2-5, the push-pull bracket I2-6, and the push-pull bracket II2-7 are connected with the slide frame 2-5, The motor 2-8 is connected with the carriage 2-5, the motor 2-8 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com