Adjustable cavitation venturi tube

A venturi tube and steam adjustment technology, applied in the direction of valve lift, shaft seal, valve details, etc., can solve the problems of poor flow control effect and poor adjustment accuracy, so as to achieve good flow control, precise flow adjustment and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

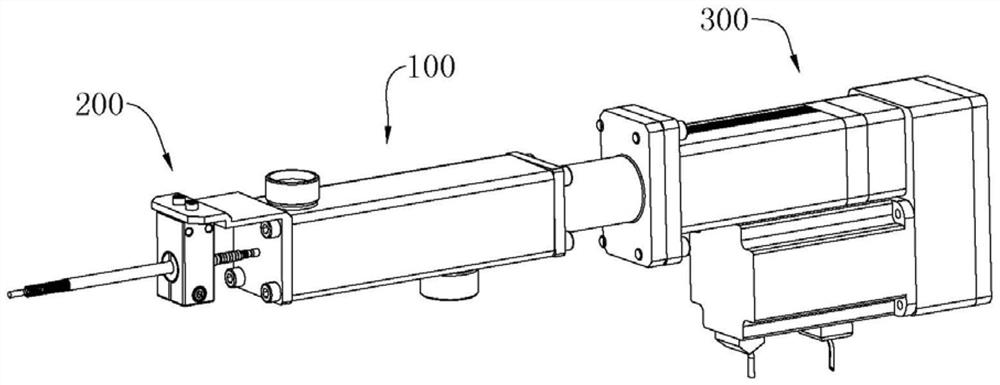

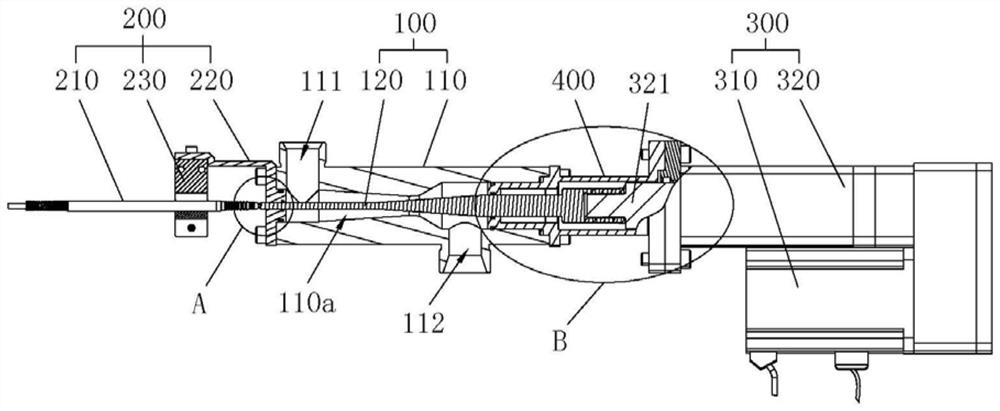

[0039] see Figure 1 to Figure 6 , an adjustable cavitation venturi provided in this embodiment, specifically relates to an adjustable cavitation venturi based on the feedback of a differential pressure variable displacement sensor 210, which is applied in the field of rocket engines and used for flow regulation .

[0040] Please refer to figure 1 and figure 2, The adjustable cavitation venturi provided in this embodiment includes: a venturi adjustment mechanism 100, a displacement detection mechanism 200, a driving mechanism 300 and a controller (not shown in the figure). Wherein, the driving mechanism 300 is arranged at one end of the venturi regulating mechanism 100 , and the driving mechanism 300 is used to drive the venturi regulating mechanism 100 for adjustment, so as to control the flow rate of the venturi regulating mechanism 100 . The displacement detection mechanism 200 is arranged at the other end of the venturi adjustment mechanism 100, and the displacement de...

Embodiment 2

[0063] see figure 1 , figure 2 as well as Figure 4 , an adjustable cavitation venturi provided in this embodiment is applied to flow regulation. This embodiment is an improvement made on the technical basis of the above-mentioned embodiment 1. Compared with the above-mentioned embodiment 1, the difference in:

[0064] The adjustable cavitation venturi provided in this embodiment also includes a limit mechanism 400, which is arranged between the driving mechanism 300 and the venturi body 110, and the limit mechanism 400 is used to limit the axis of the spool 120. to the displacement.

[0065] Specifically, the limit mechanism 400 includes a limit sleeve 400a, the limit sleeve 400a is sleeved on the valve core 120, the limit sleeve 400a is provided with a limit boss 410, and the limit boss 410 and the shoulder on the valve core 120 For touch fit. Optionally, the limiting boss 410 is circular and arranged along the circumference of the inner wall of the limiting sleeve 400...

Embodiment 3

[0071] see figure 2 , Figure 5 as well as Figure 6 , an adjustable cavitation venturi provided in this embodiment is applied to flow regulation. This embodiment is an improvement made on the technical basis of the first or second embodiment above. Or embodiment two, the difference is:

[0072] In this embodiment, the axial section of the throat 114 is trapezoidal, preferably isosceles trapezoidal. That is to say, the shape of the throat 114 is a truncated circular cavity. The spool 120 is provided with a cone section 121 corresponding to the position of the throat 114, wherein the outer wall surface of the cone section 121 is parallel to the inner wall surface of the throat 114, so that the minimum flow section of the throat 114 of the venturi body 110 is no longer is a specific section. That is to say, after the outer wall surface of the cone section 121 is parallel to the inner wall surface of the throat 114, a series of equal-area flow cross-sections are formed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com