Rotor with low electromagnetic torque ripple and low noise and parametric modeling method thereof

A torque ripple, low electromagnetic technology, applied in the field of low electromagnetic torque ripple and low noise rotor and its parametric modeling, to achieve harmonic amplitude reduction, electromagnetic radial force reduction, reduce electromagnetic torque ripple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

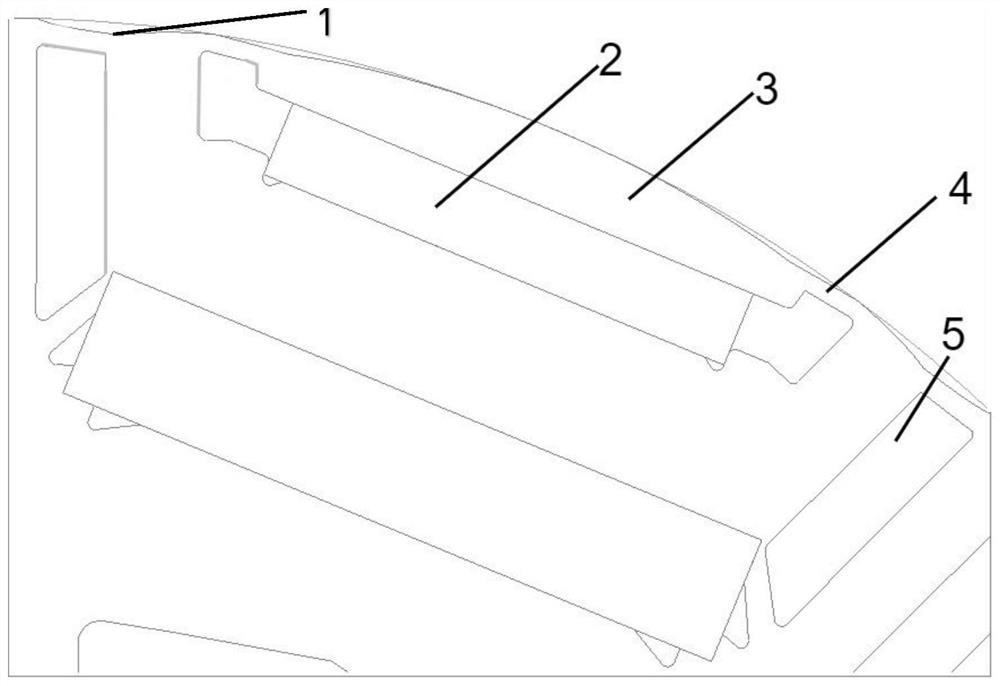

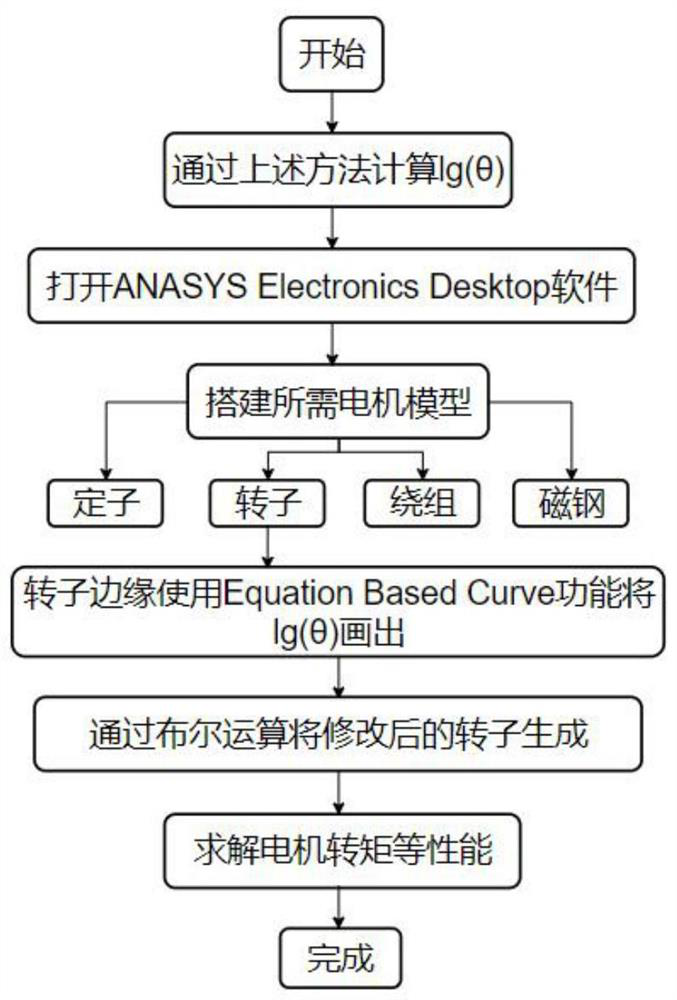

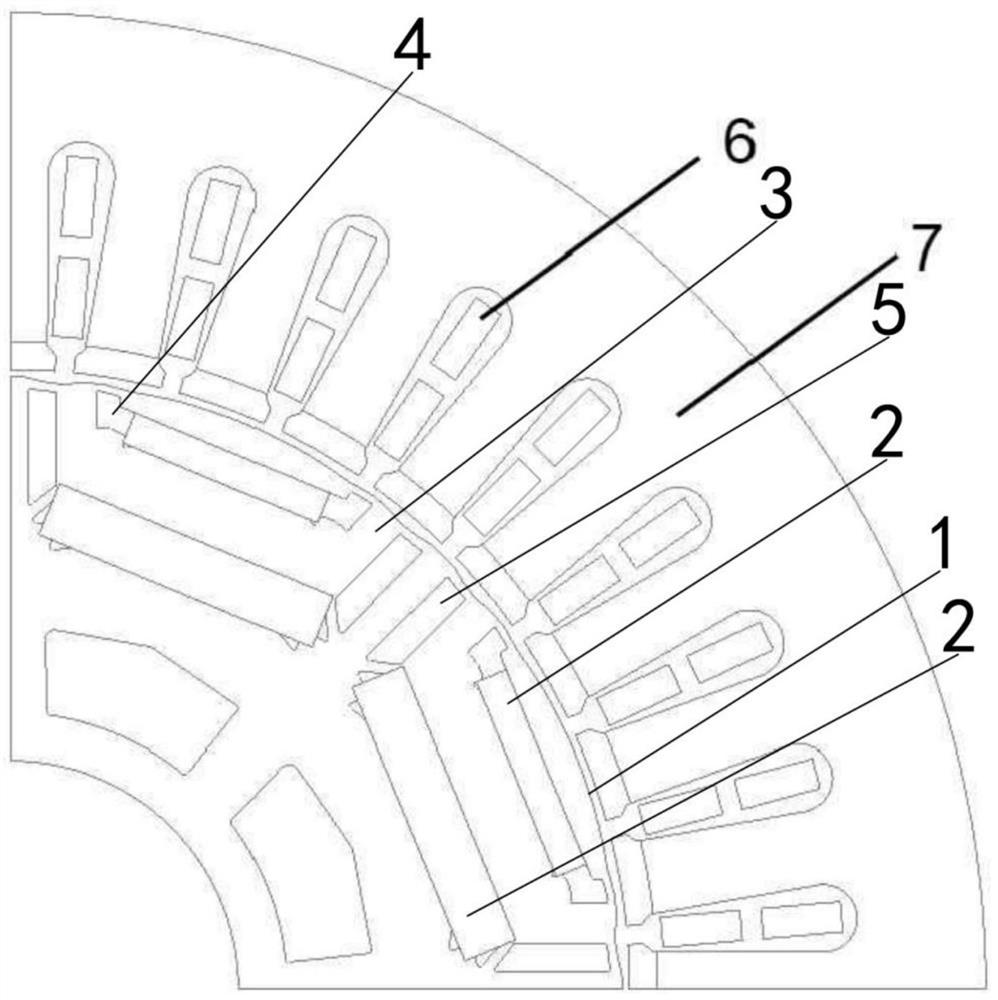

[0034] Example: See Figure 1-6 A low-electromagnetic tum torque pulsation and low noise rotor comprise a rotor core 3, and the rotor core 3 is uniformly disposed in its circumferential direction, each of the magnetic poles is formed by two magnetic steel 2, rotor iron The core 3 is provided between the adjacent two magnetic poles, and there is a air tank 5 between the adjacent absorber 4, and the outer contour of the rotor core 3 is cut into segmented anti-surpass function curves, specifically See figure 1 , 3 The rotor core edge 1 in 6, the segmented anti-cosine function curve of the outer contour of the rotor core 3 is determined by the following formula:

[0035]

[0036] In L g (θ) is air gap length, B m Is the air gap magnetic flux density generated by the magnetic steel 2 when the rotor did not change the rotor, L g For the initial length of the air gap, k is the magnitude of the air gap magnetic tester after changing the rotor shape;

[0037] Among them, a plurality of ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com