Novel 10 kv environment-friendly gas all-insulated switch cabinet

A fully insulated, switchgear technology, applied in the field of switchgear, can solve the problems of endangering personal or equipment safety, high production cost, affecting production, etc., to avoid erroneous and illegal operations, enhance safety, and avoid arc hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiment of the present invention will be described in detail below, and the examples of the embodiments are intended to be described in order to explain the invention, and is not to be understood to limit the embodiments of the invention, and in the examples are not specifically described in the art. Techniques or conditions or according to the product description, the instrument used is not indicated, all of which can be obtained through the commercially available conventional products.

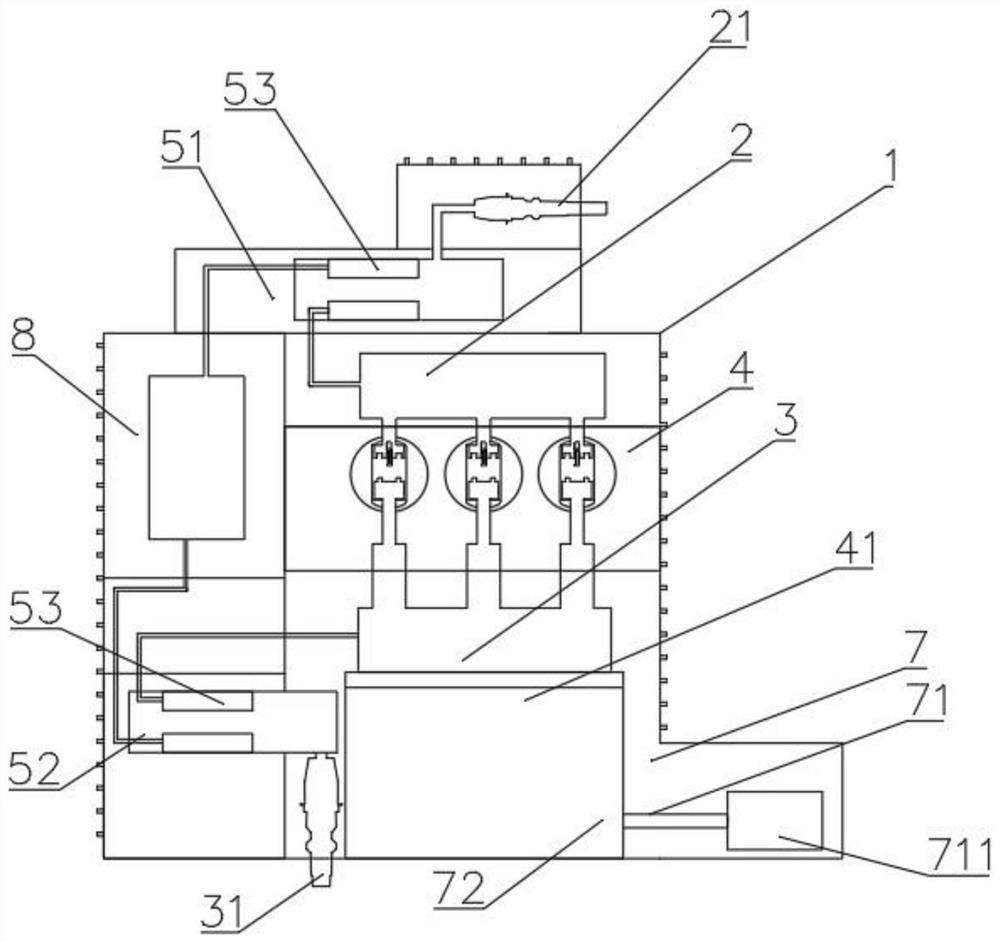

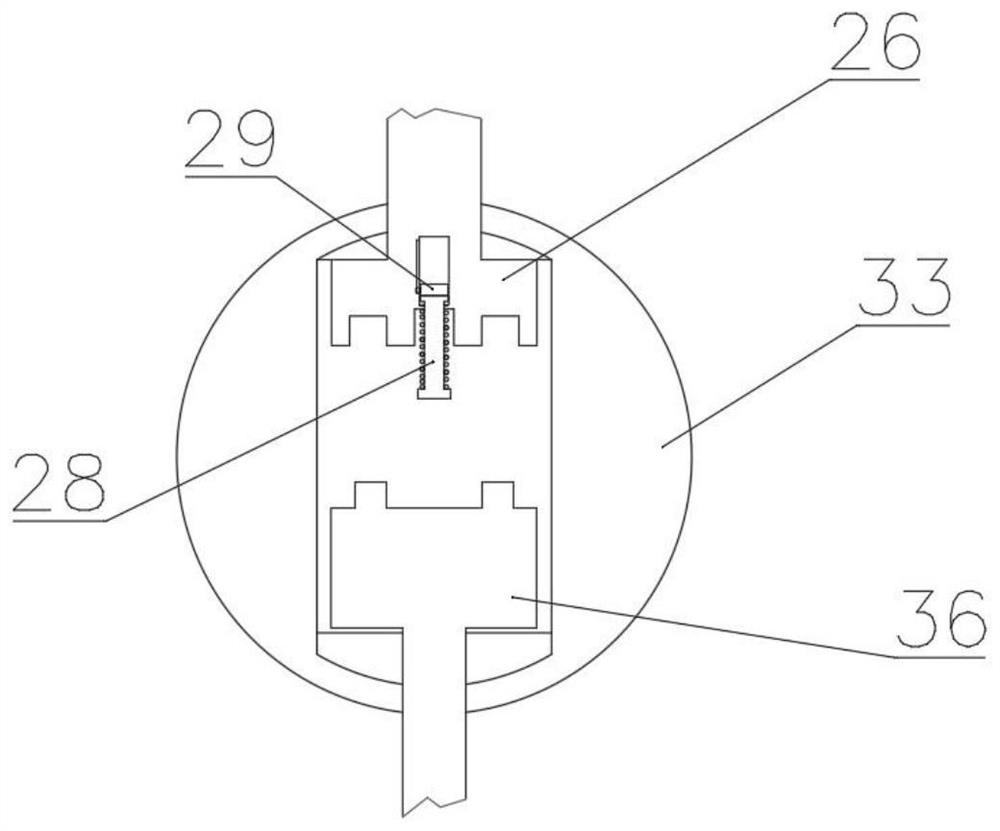

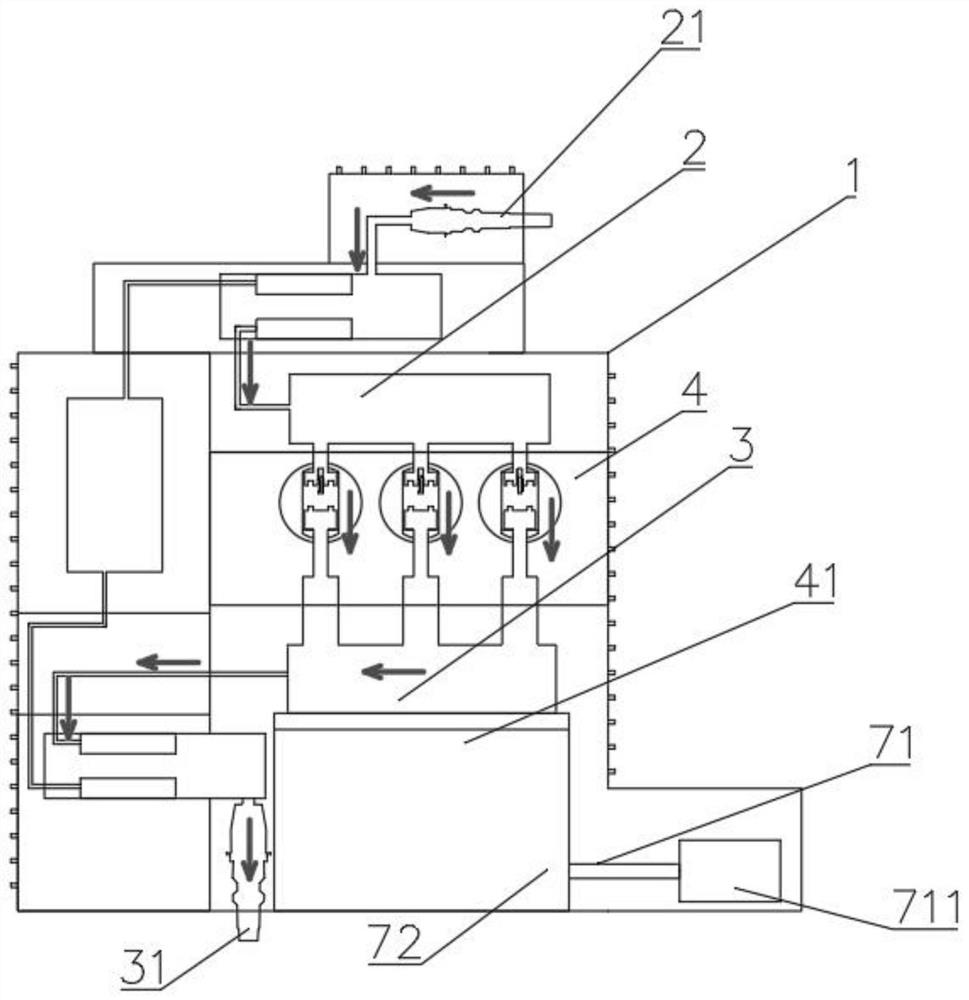

[0028] like Figure 1-4 A new 10kV environmentally friendly gas is fully insulated, including:

[0029] The cabinet 1, provided with a control assembly, the operation of each component in the intelligent control cabinet 1 in the power-on state, the main bus assembly 2 is located in the cabinet 1, and the circuit breaker assembly 3 is set to the main bus assembly 2, through the lifting mechanism. 41 Unicom line;

[0030] The main bus assembly 2 is fixed to the top of the lumen of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com